Introduction 1

1

2

3

4

5

6

7

8

9

11

The 3169-20 and the 3169-21 Clamp On Power HiTester is supplied with a

instruction manual in addition to this manual. Please be sure to read both

manuals.

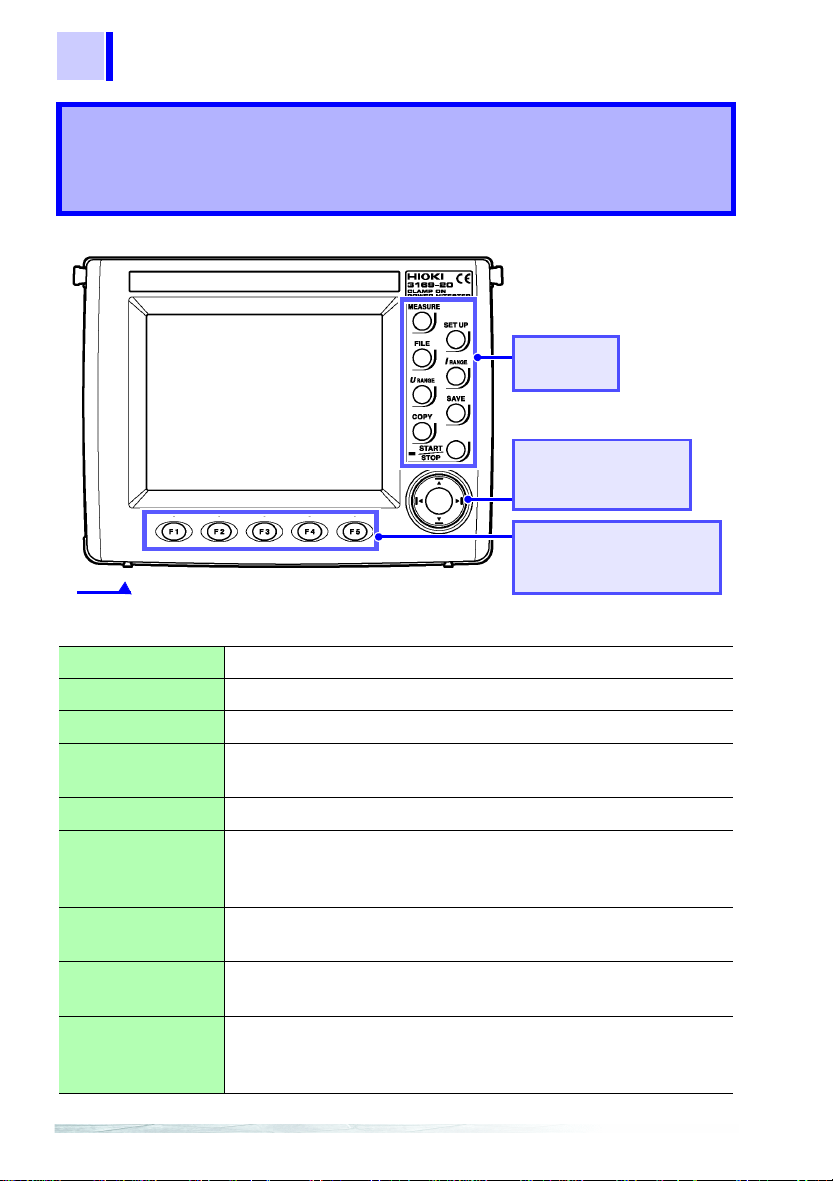

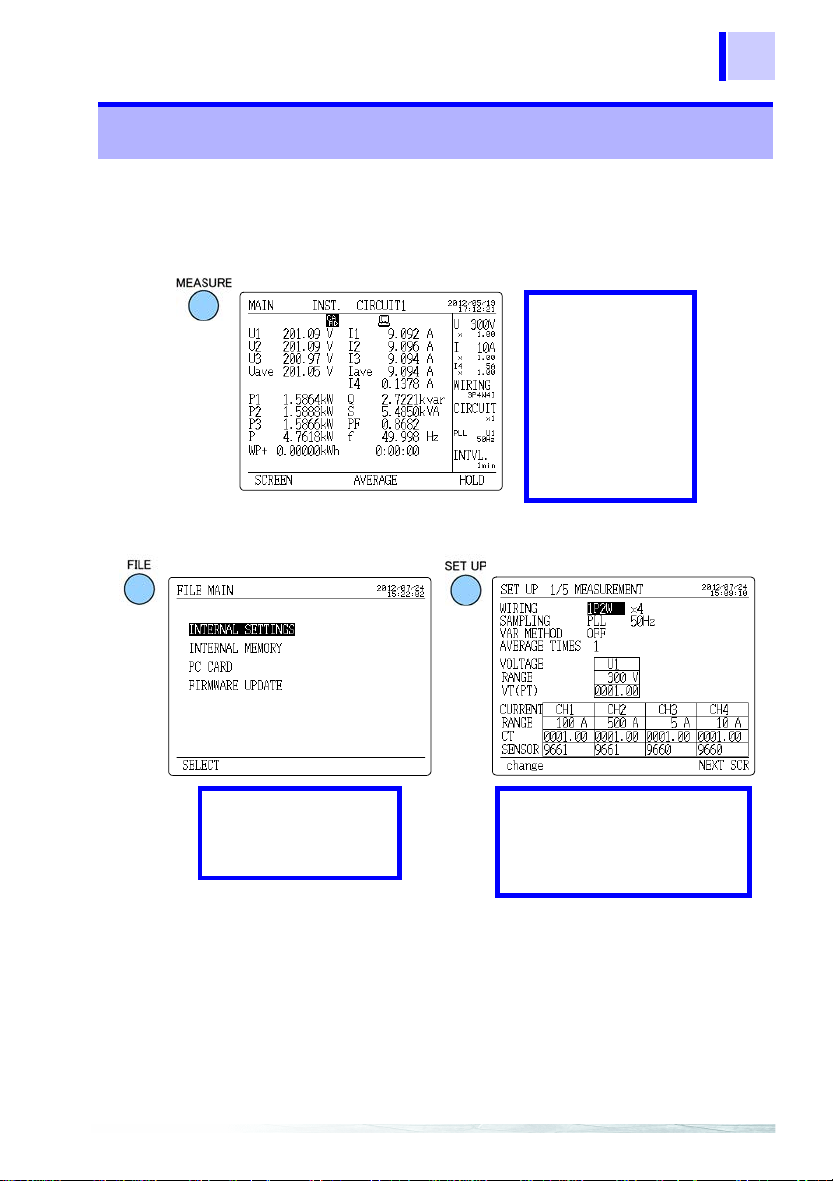

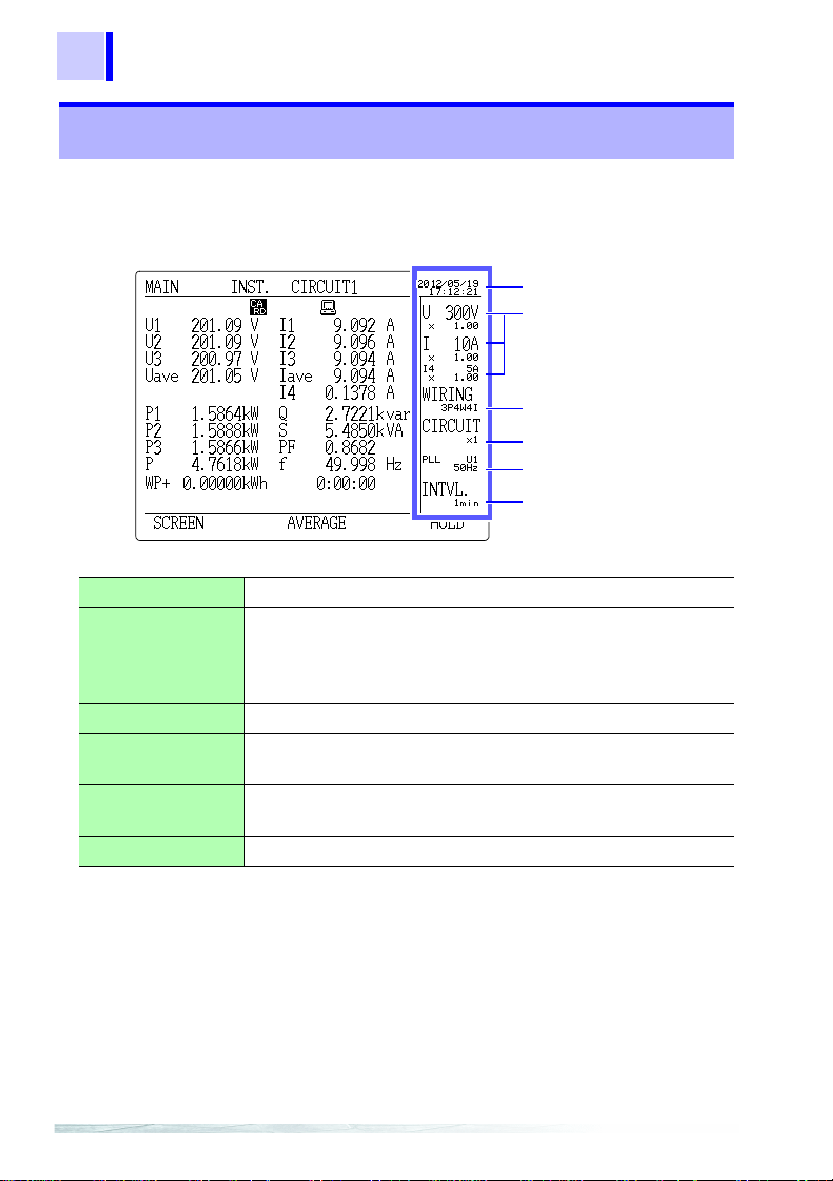

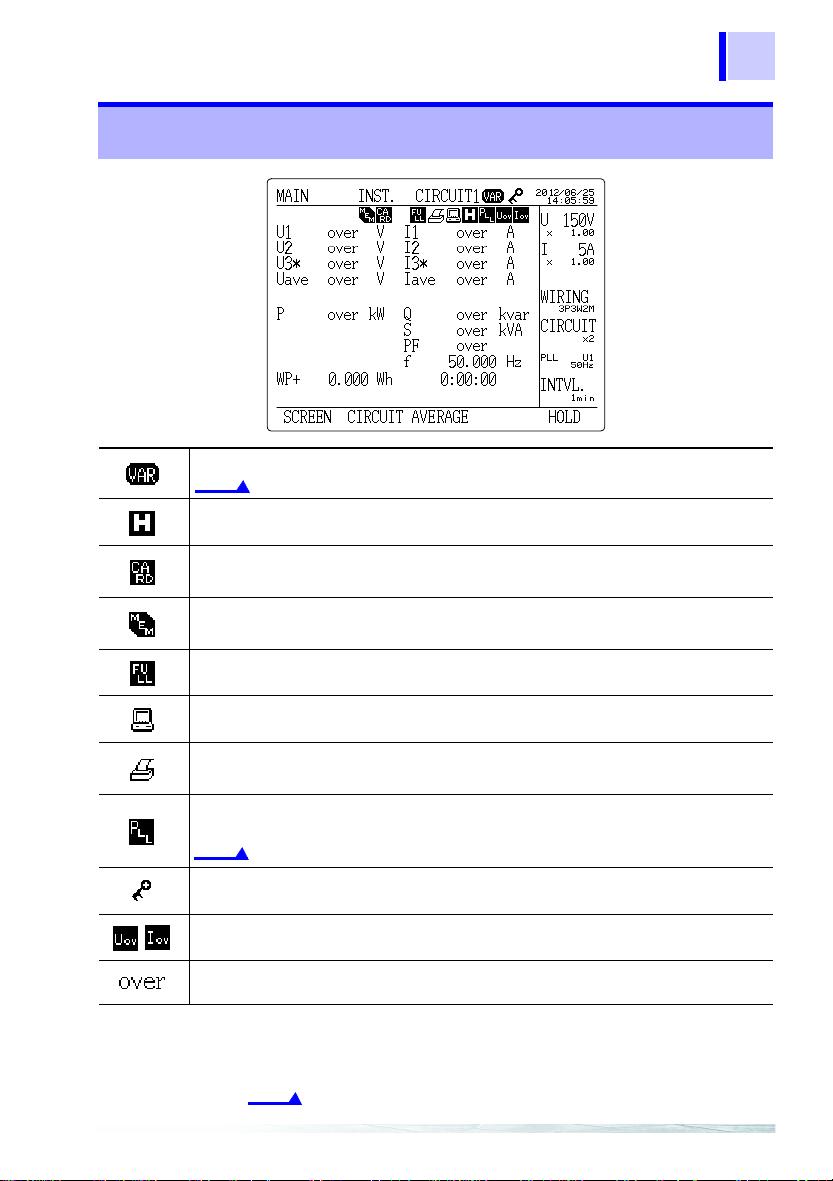

This manual provides a simplified description of the instrument (key names

and functions as well as screens) and measurement process, from the prepa-

ration stage to the completion of measurement, using an example application.

For current input with this instrument, a clamp-on sensor (optional) is

required. For details, refer to the instruction manual for the clamp-on sensor

you are using.

Be sure to review the instruction manual carefully before using the instru-

ment to ensure safe operation.

Model Numbers

In this manual, "3169" is used as the instrument model.

M

Notation

In this manual, the risk seriousness and the hazard levels are classified as

follows.

Introduction

Model No. D/A output function

3169-20 Not available

3169-21 Available

Indicates an imminently hazardous situation that will result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in minor or

moderate injury to the operator or damage to the instrument or mal-

function.

Indicates prohibited actions.

Indicates the reference.

Indicates a useful measurement tip or fact.

*Additional information is presented below.