Copyright HK Instruments 2022 www.hkinstruments. Installaon version 1.0 2022

INSTALLATION

INSTRUCTIONS

DIFFERENTIAL PRESSURE TRANSMITTERS

DPT-CR-MOD Series

• READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THIS

DEVICE.

• Failuretoobservesafetyinformaonandcomplywith

instruconscanresultinPERSONALINJURY,DEATHAND/OR

PROPERTY DAMAGE.

• Toavoidelectricalshockordamagetoequipment,disconnect

powerbeforeinstallingorservicinganduseonlywiringwith

insulaonratedforfulldeviceoperangvoltage.

• Toavoidpotenalreand/orexplosiondonotuseinpotenally

ammableorexplosiveatmospheres.

• Retaintheseinstruconsforfuturereference.

• Thisproduct,wheninstalled,willbepartofanengineered

systemwhosespecicaonsandperformancecharacteriscs

arenotdesignedorcontrolledbyHKInstruments.Review

applicaonsandnaonalandlocalcodestoassurethatthe

installaonwillbefunconalandsafe.Useonlyexperiencedand

knowledgeabletechnicianstoinstallthisdevice.

ThankyouforchoosinganHKInstrumentsDPT-CR-MODseriesdif-

ferenalpressuretransmier.DPT-CR-MODseriesisdesignedspe-

ciallyforcleanroommonitoring.Inaddiontodierenalpressure,

thedeviceenablesmonitoringtemperatureandrelavehumidity.

A 0…10 V voltage input of an external humidity and temperature

transmiercanbeconnectedtotheinputterminalofthedevice.In

thiscase,all three measuredvalues(dierenalpressure,relave

humidity,temperature)willbeshownsimultaneouslyonthedisplay.

Alternavely,apassivetemperaturesensorcanbeconnectedtothe

inputterminal.

DPT-CR-MOD is compable with Modbus serial communicaon

protocol.

DPT-CR-MODseriesdevicesarecommonlyusedinHVAC/R

systems for:

•pressure,temperatureandhumiditymonitoringincleanrooms

SPECIFICATIONS

Performance

Measurement range:

-250...2500Pa

Accuracy (from applied pressure):

Pressure<125Pa=1%+±2Pa

Pressure>125Pa=1%+±1Pa

(Including:generalaccuracy,linearity,

hysteresis,longtermstabilityandrepeonerror)

Input accuracy:

Temperature:±0.25°Ctypical@25°C+accuracyof

externaltransmier

Humidity:±0.5%rHtypical@25°C+accuracyof

externaltransmier

Overpressure:

Proofpressure:25kPa

Burstpressure:30kPa

Zero point calibraon:

ManualpushbuonorviaModbus

Response me:

1...20sselectableviamenu

Communicaon

Protocol:MODBUSoverSerialLine

TransmissionMode:RTU

Interface:RS485

Byteformat(11bits)inRTUmode:

CodingSystem:8-bitbinary

BitsperByte:

1 start bit

8databits,leastsignicantbitsent

rst

1bitforparity

1stopbit

Baudrate:selectableinconguraon

Modbusaddress:1−247addressesselectablein

conguraonmenu

Technical Specicaons

Media compability:

Dryairornon-aggressivegases

Measuring units:

Selectableviamenu(Pa,mbar,inchWC,mmWC,psi)

Measuring element:

MEMS,noow-through

Environment:

Operangtemperature:-20...50°C

Temperaturecompensatedrange0...50°C

Storagetemperature:-40...70°C

Humidity:0to95%rH,non-condensing

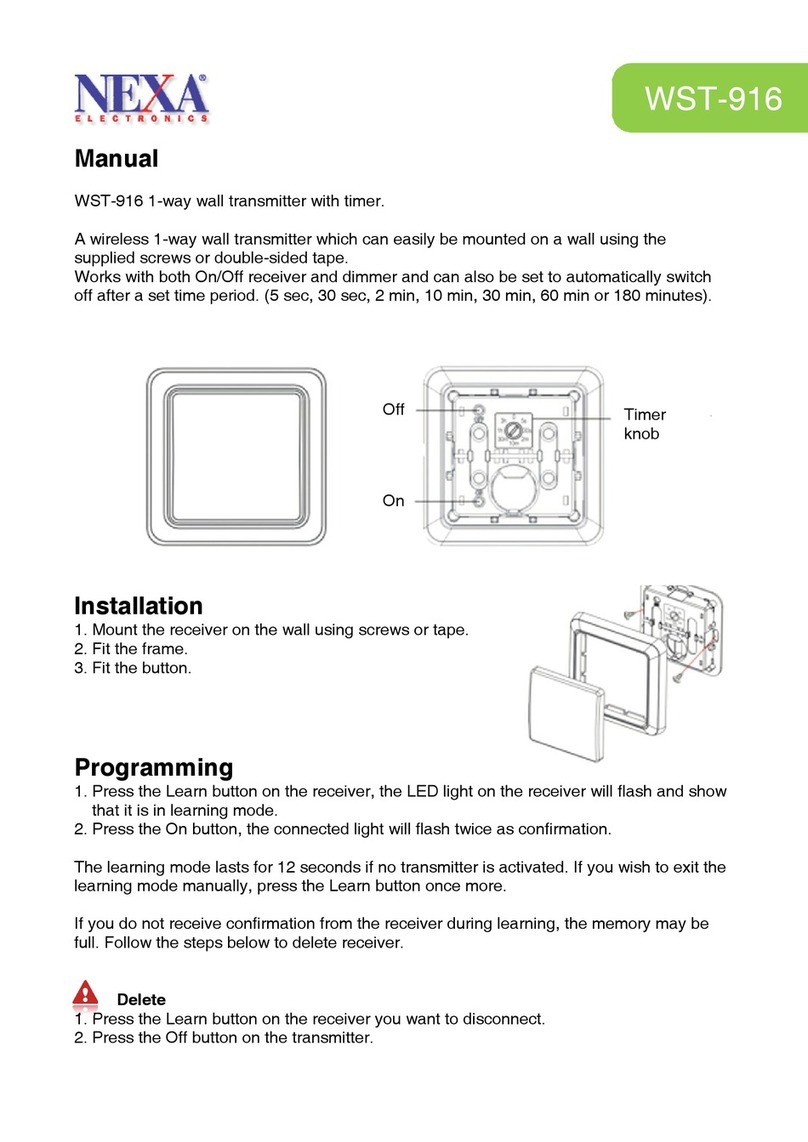

Physical

Dimensions:

Case:102x71.5x36mm

Weight:

150g

Mounng:

2each4.3mmscrewholes,onesloed

Materials:

Case: ABS

Lid:PC

Pressure inlets: Brass

Protecon standard:

IP54

Display:

2-linedisplay(12characters/line)

Line1:pressuremeasurement

Line2:relavehumidityandtemperature(ifexternal

measurementsareconnected)

Electrical Connecons:

4+4springloadterminals,max1.5mm2

Cableentry:M20

Pressure ngs:

Maleø5.2mm

+Highpressure

-Lowpressure

Electrical

Supply voltage:

24VACorVDC±10%

Power consumpon:

<1.3W

Output signal:

viaModbus

Input signals:

Temperatureinput:0−10VorNTC10k,Pt1000,

Ni1000/(-LG)

RHinput:0−10V

Conformance

Meetsrequirementsfor:

CE: UKCA:

EMC: 2014/30/EU S.I.2016/1091

RoHS: 2011/65/EU S.I.2012/3032

WEEE: 2012/19/EU S.I.2013/3113

INTRODUCTION

APPLICATIONS

WARNING

RoHS