2hms-tness.com

NOTES CONCERNIGN SAFETY

This product is intended only for home use and has been designed to ensure opmal safety.

The following rules shall be obeyed:

1. Before starng your workout, consult your physician to check if there are any reasons prevenng the use of this tness equip-

ment. The doctor’s decision is required if you take medicines that aect your heart work, blood pressure and levels of cholesterol.

It is also necessary in the case of persons aged over 35 and people with health problems.

2. Always do your warm-up before training.

3. During exercise and aer its compleon the training equipment should be protected from children and animals.

4. The equipment shall be placed on dry, stable and properly levelled surface. All sharp objects shall be removed from its direct

vicinity. The equipment should be protected from humidity. Possible surface irregularies should be levelled. It is recommended

to use special an-slip base to prevent the equipment displacement during workout.

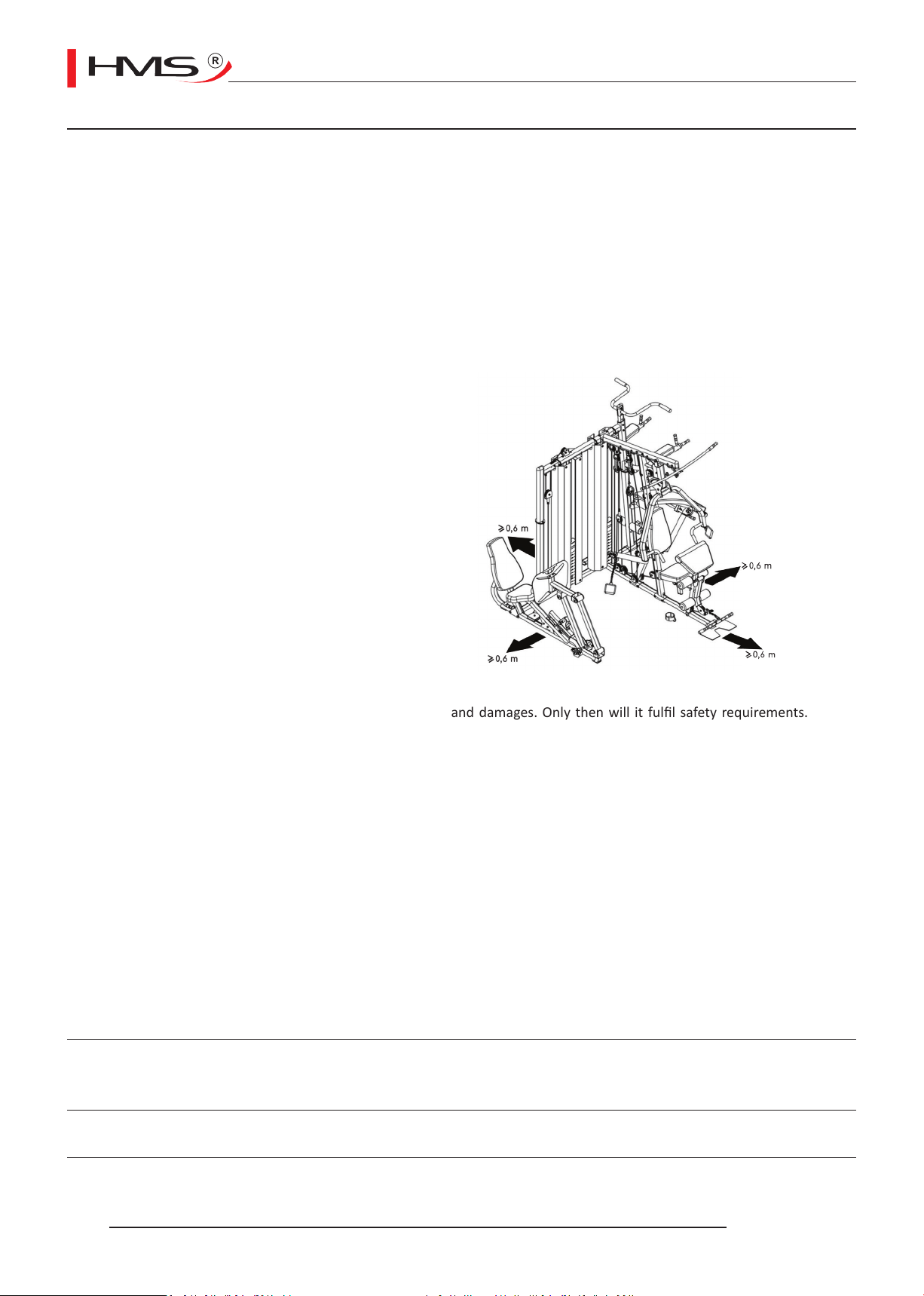

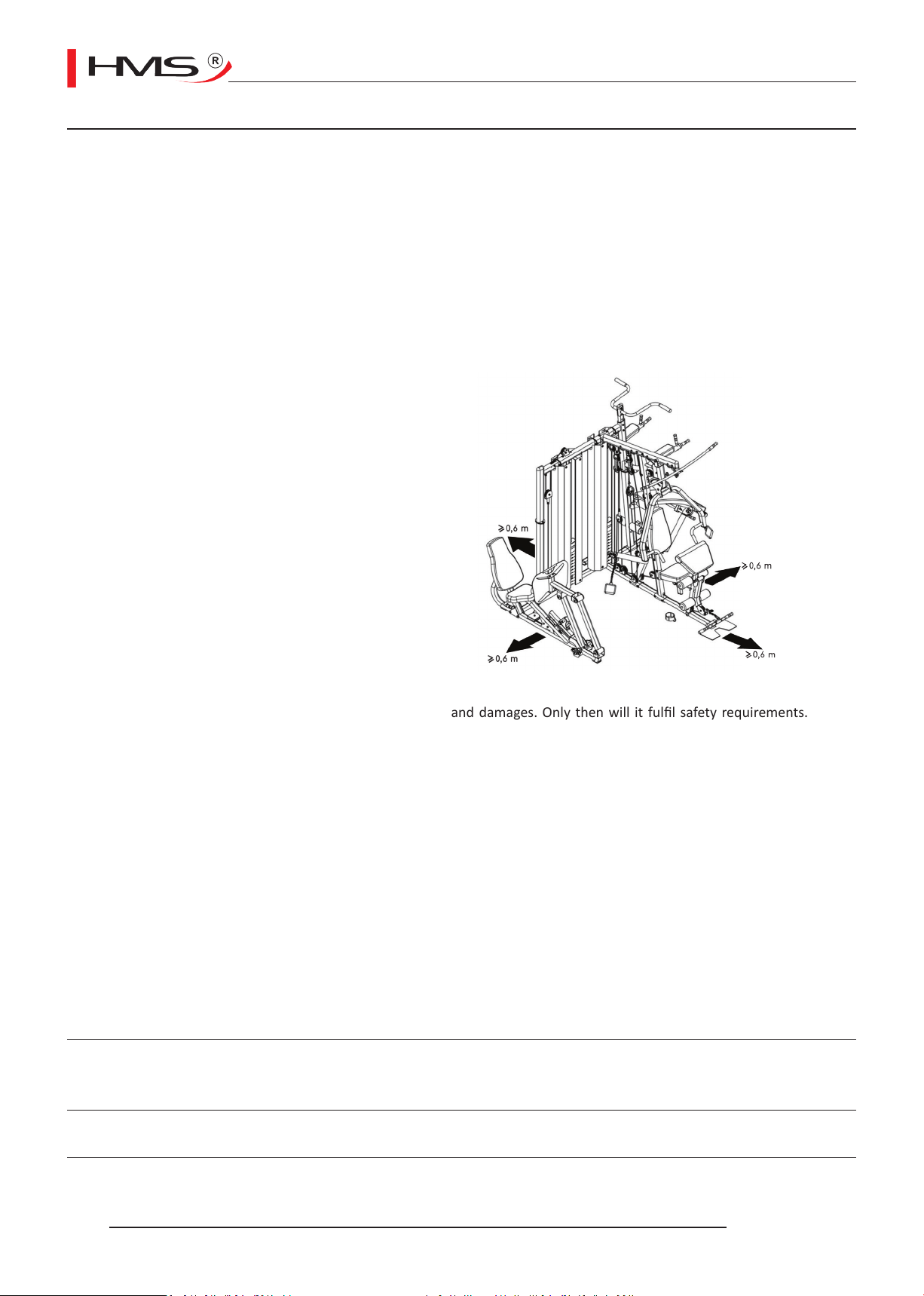

5. Free space should not be smaller than 0.6 m and

greater. Pay aenon to worrying signals. Incor-

rect or excessive exercising means health hazard.

If headache or dizziness, chest pain, irregular heart

rhythm or other worrying symptoms appear during

training, the workout shall be stopped immediately

and a doctor shall be consulted. Incorrect or over-in-

tensive training can lead to traumas.

6. than the training space available in direcons of

the equipment accessibility. Free space must also

include space for emergency quing. If dierent

pieces of equipment are located side by side, the

size of free space can be divided.

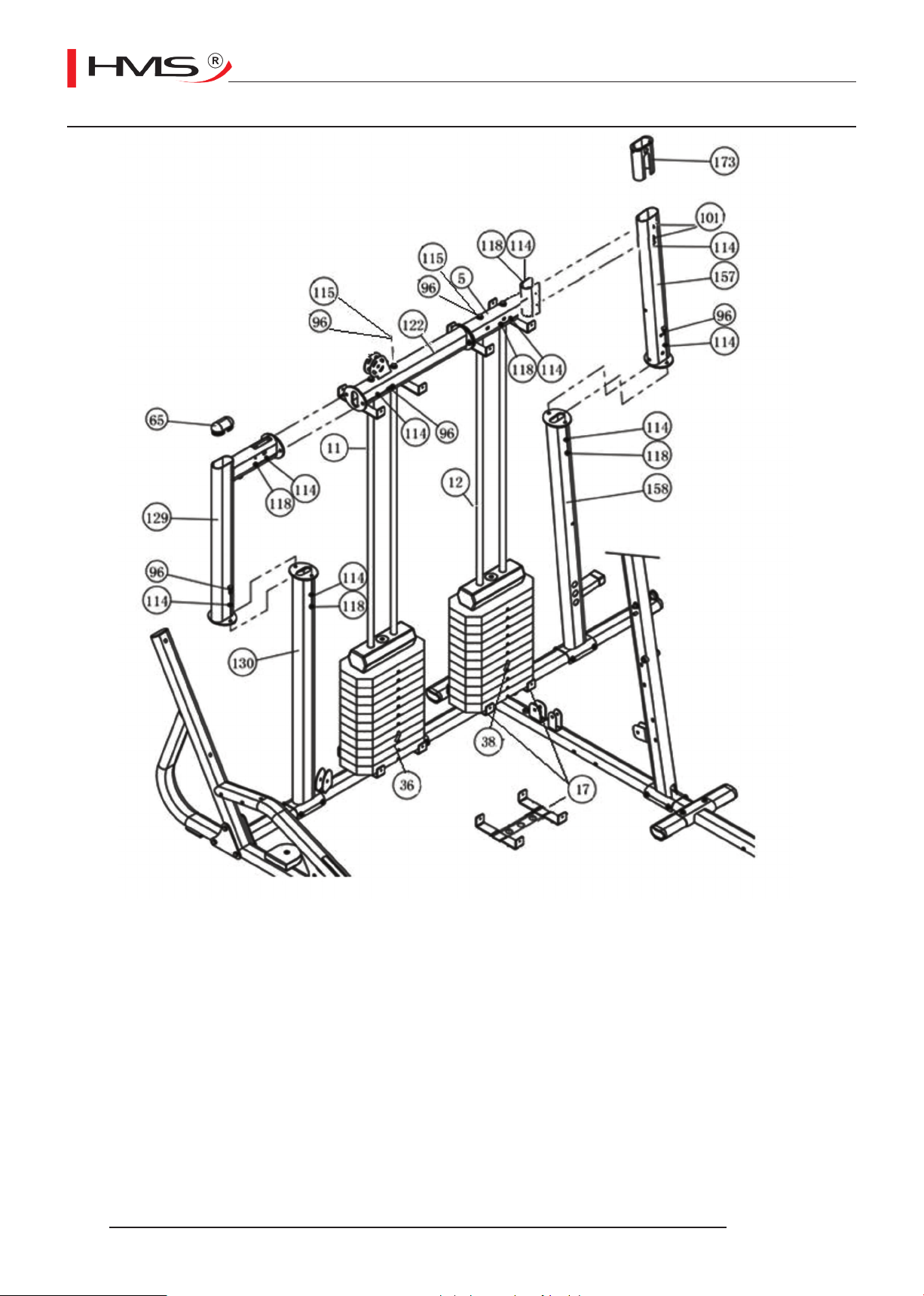

7. Before the rst use, and later at regular intervals,

ghtness of all screws, bolts and other joints shall

be checked.

8. Before starng your exercise, check xing of parts

and joints between them. Workout can be started

only if the equipment is fully operaonal.

9. The equipment shall be regularly checked for wearing-out and damages. Only then will it full safety requirements. Special

aenon shall be paid to foam grips, caps on legs and upholstery, which are all fast wearing parts. Damaged parts shall be imme-

diately repaired or replaced. Unl then, the training equipment cannot be used.

10. Do not put any elements into openings.

11. Pay aenon to protruding adjustment devices and other structural elements that might hinder exercise.

12. The equipment can only be used according to its intended purpose. If any parts wears out or is damaged, or if you hear wor-

rying sounds when using the equipment, you should immediately stop exercising. Do not use the equipment again unl the pro-

blem is removed.

13. Wear comfortable clothes and sport shoes for training. Avoid loose clothes that might catch protruding parts of the equipment

or limit your mobility.

14. The equipment falls into class H according to standard EN ISO 20957-1 and is intended for home use only. It cannot serve the-

rapeuc, rehab or commercial purposes.

15. When liing or moving the equipment, maintain correct posture to avoid spine injuries.

16. The product is intended for adults only. Keep children without supervision away from the equipment.

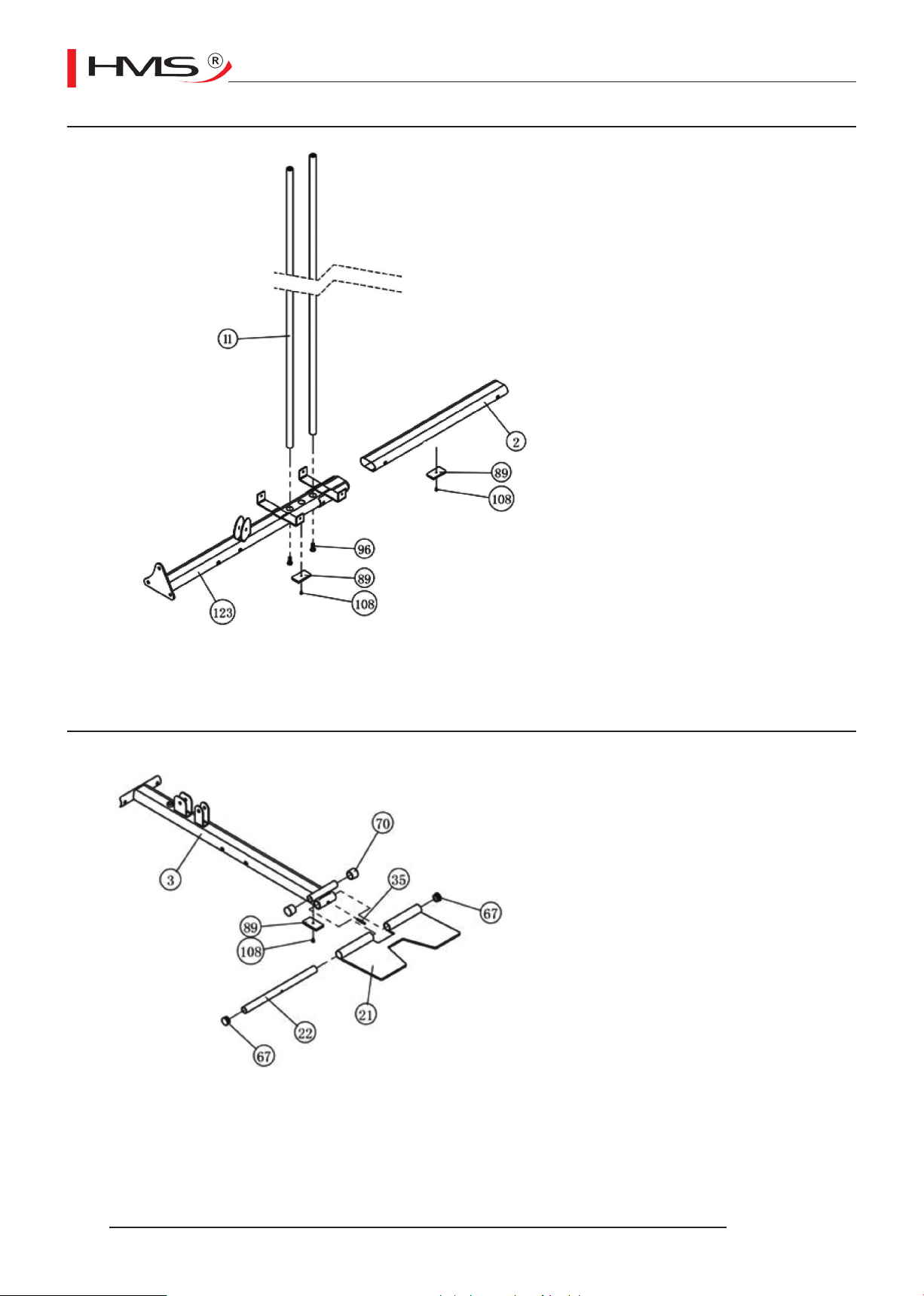

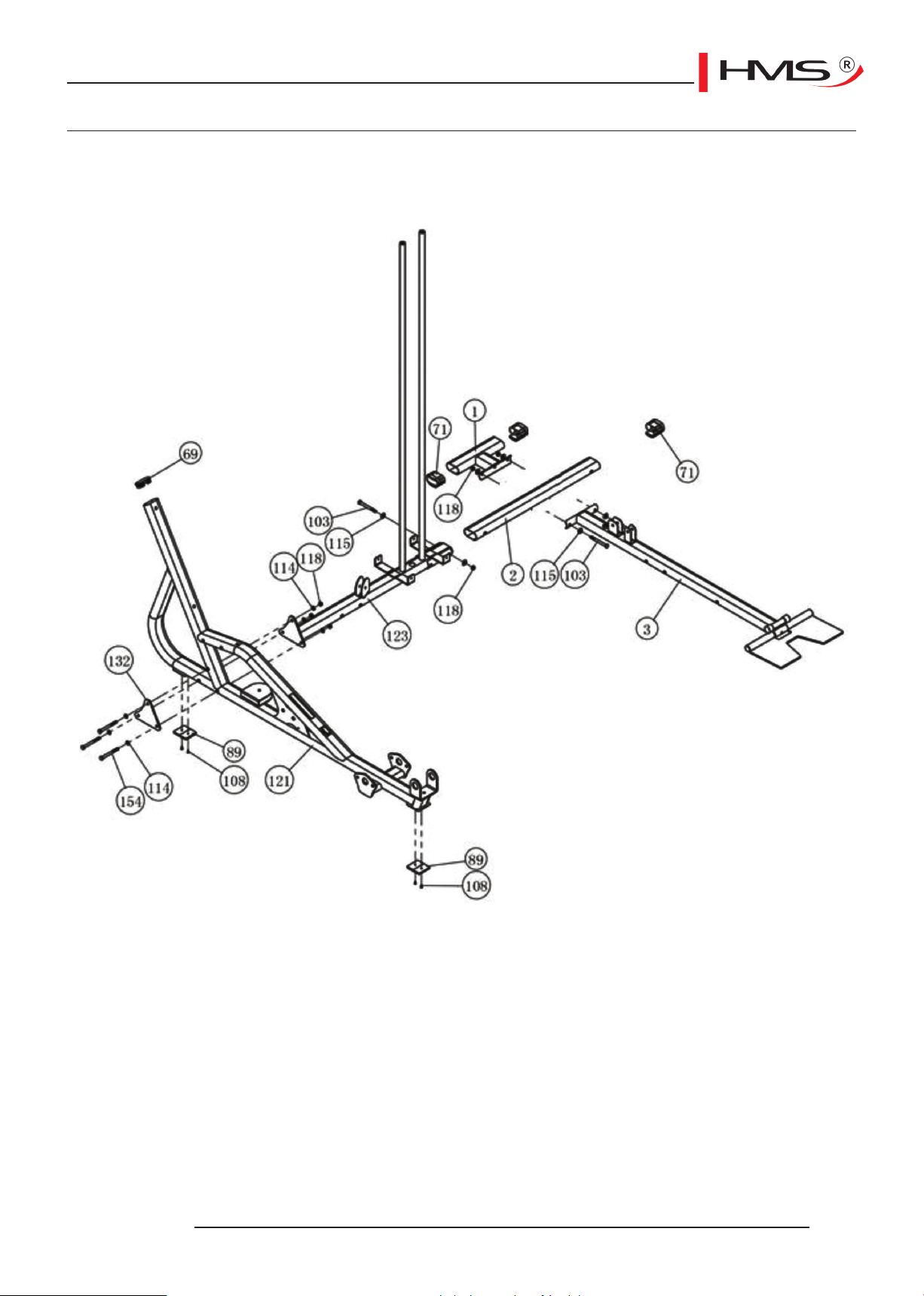

17. During installaon, follow closely the aached manual instrucon and use only such parts that have been included in the pac-

kage. Before installaon, check if all parts from the list are included in the package.

WARNING: READ THE INSTRUCTION BEFORE USING THE EQUIPMENT.

WE ARE NOT REPONSIBLE FOR INJURIES OR DAMAGES TO OBJECTS CAUSED BY INCORRECT USE OF THE PRODUCT

MAINTENANCE: No aggressive cleaning agents shall be used to clean the equipment. Use a so, wet cloth to remove dirt and dust. The

equipment shall be kept in dry places and protected from humidity and corrosion.

TECHNICAL DATA: Net weight – 370 kg

Dimensions when unfolded – 246 x 332 x 218 cm

Maximum permissible loading of the product – 140 kg