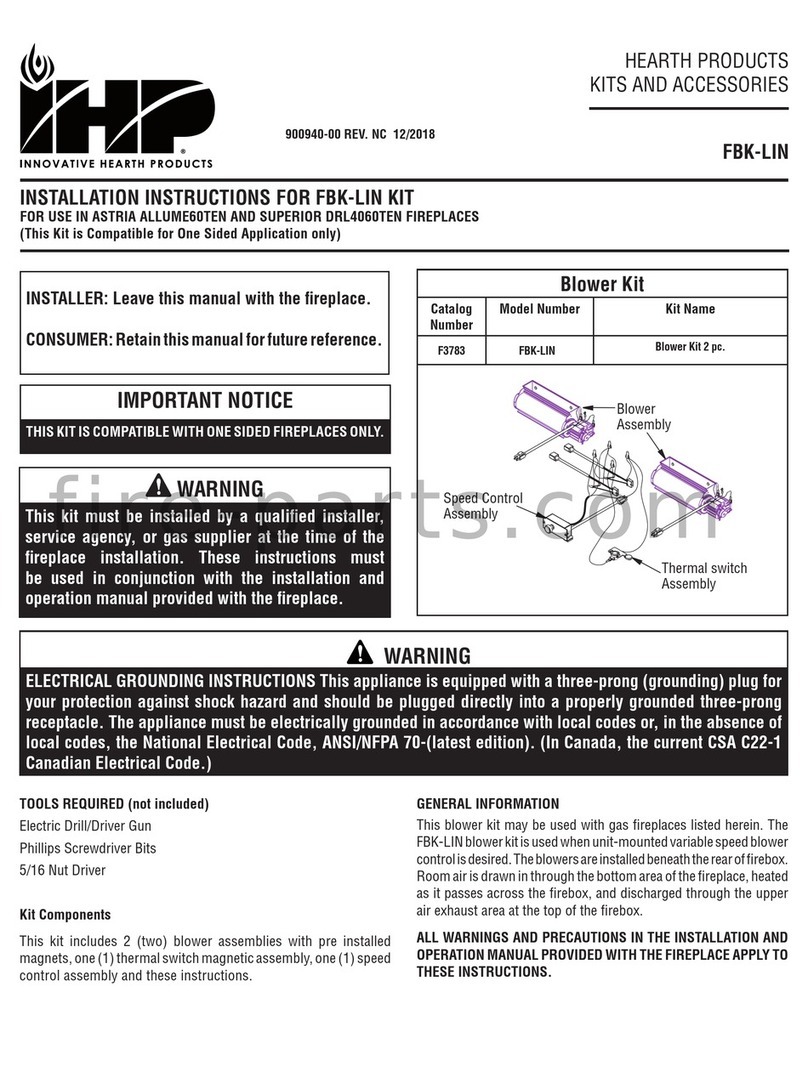

KIT CONTENTS

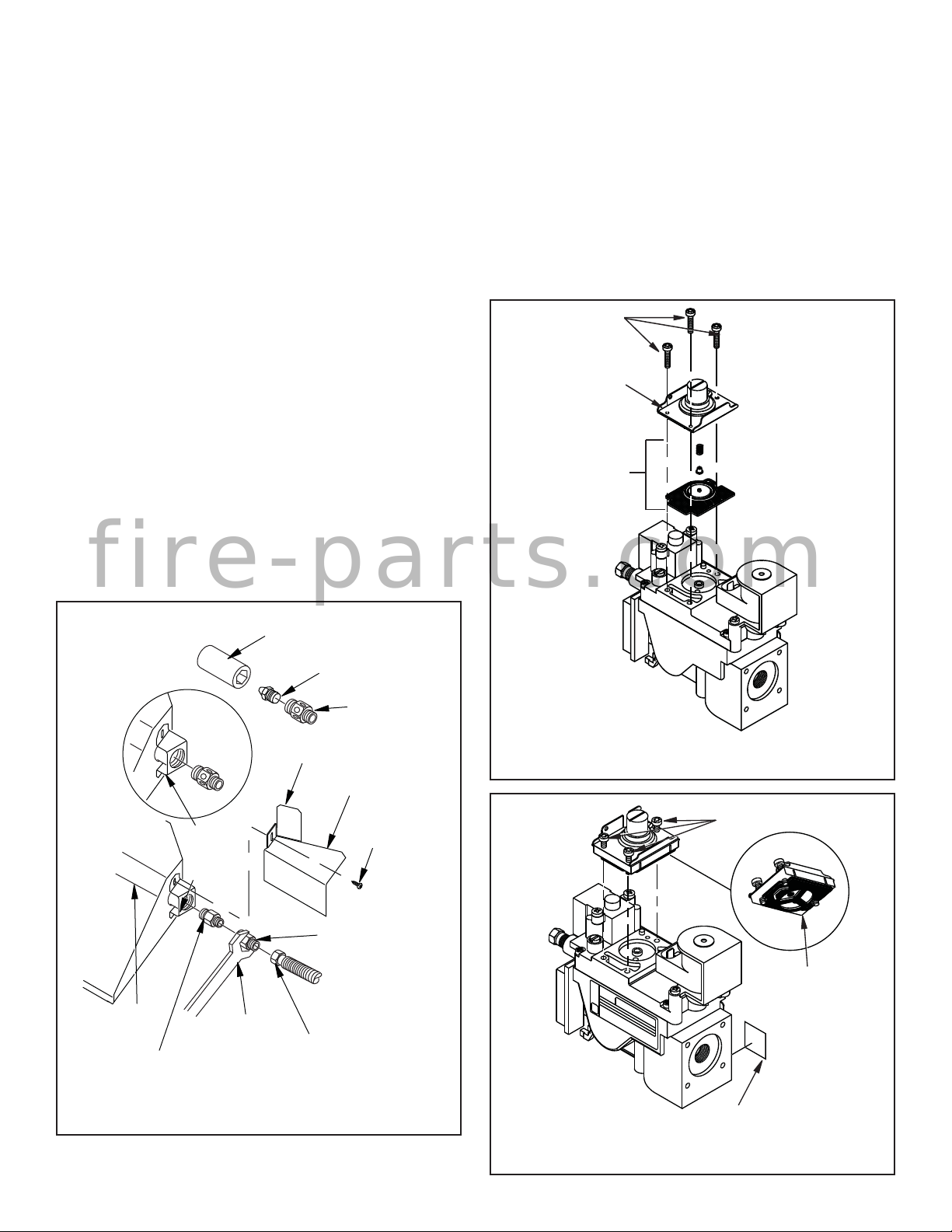

1 ea. Pilot Orifice LP (#14)

1 ea. Main Burner Orifice (#54)

1 ea. Air-Mixer Brass LP

1 ea. Gas Valve Regulator LP

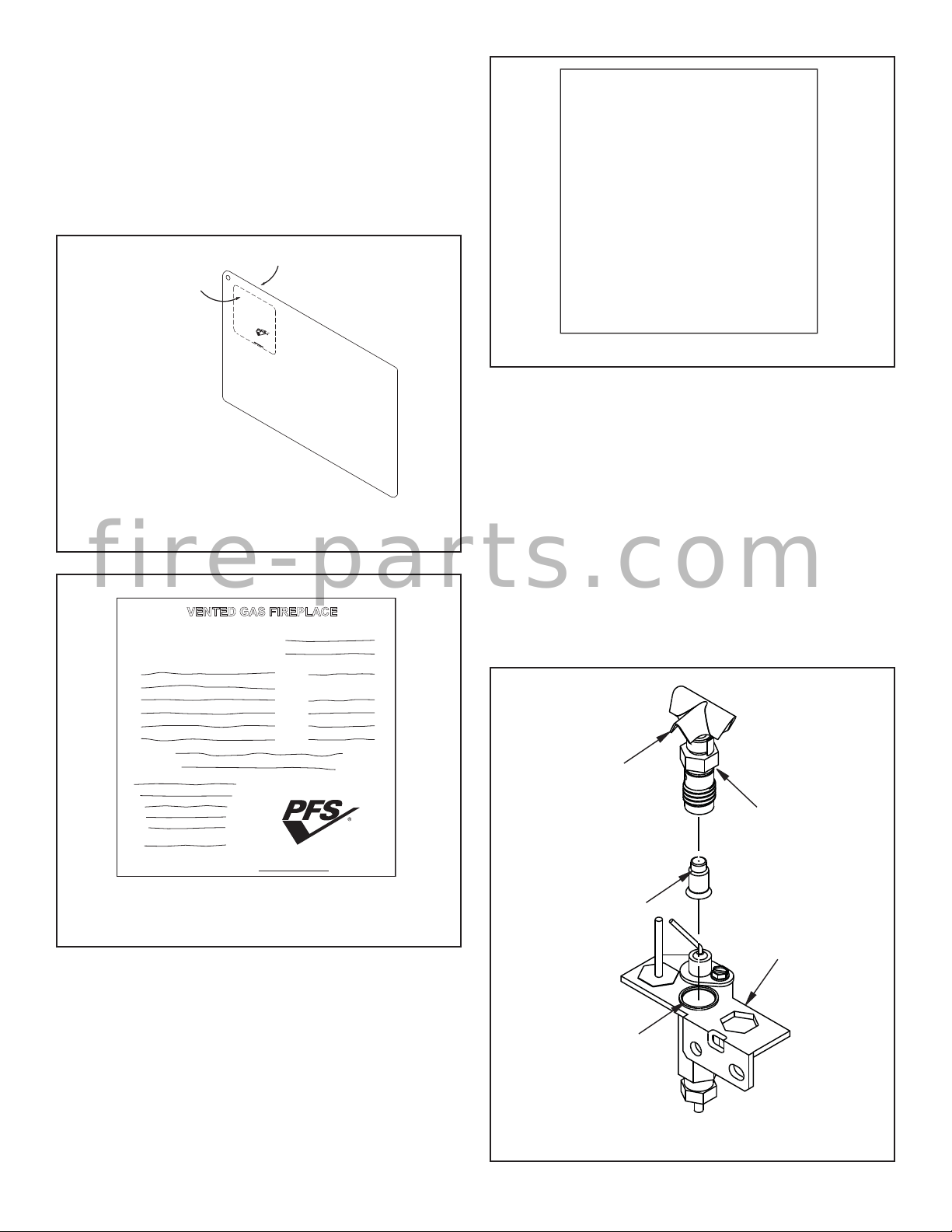

1 ea. Conversion Label, English

1 ea. Conversion Label, French

1 ea. Conversion Information Label

1 ea. Instruction Sheet

REQUIRED TOOLS AND SUPPLIES

7/8” Open End Wrench or Adjustable Wrench

3/4” Open End Wrench or Adjustable Wrench

3/8” Deep Socket Drive

Torx T20 or Slotted Screwdriver

5/32” Allen Wrench

#2 Short Phillips Screwdriver

Thread Sealant (Resistant to Propane/LP)

TURN OFF THE GAS SUPPLY TO THE APPLIANCE. DISCONNECT

ELECTRICAL POWER SUPPLY.

READ ALL THE STEPS BEFORE STARTING THE CONVERSION. IN-

STALLER NOTICE: THESE INSTRUCTIONS MUST BE LEFT WITH THE

APPLIANCE.

When installing gas components use pipe joint compound or

Teflon tape on all pipe fittings before installing (Do not use pipe

joint compounds on flare fittings).

THE APPLIANCE MUST BE OFF AND COLD BEFORE PERFORMING

THE GAS CONVERSION.

ALL WARNINGS, PRECAUTIONS AND INSTRUCTIONS IN THE INSTAL-

LATION AND OPERATION MANUAL PROVIDED WITH THE APPLIANCE

APPLY TO THESE INSTRUCTIONS.

GENERAL INFORMATION

Gas conversion kits are available to adapt the appliance from the

use of one type of gas to the use of another. These kits contain all

the necessary components needed to complete the task including

labeling that must be affixed to ensure safe operation.

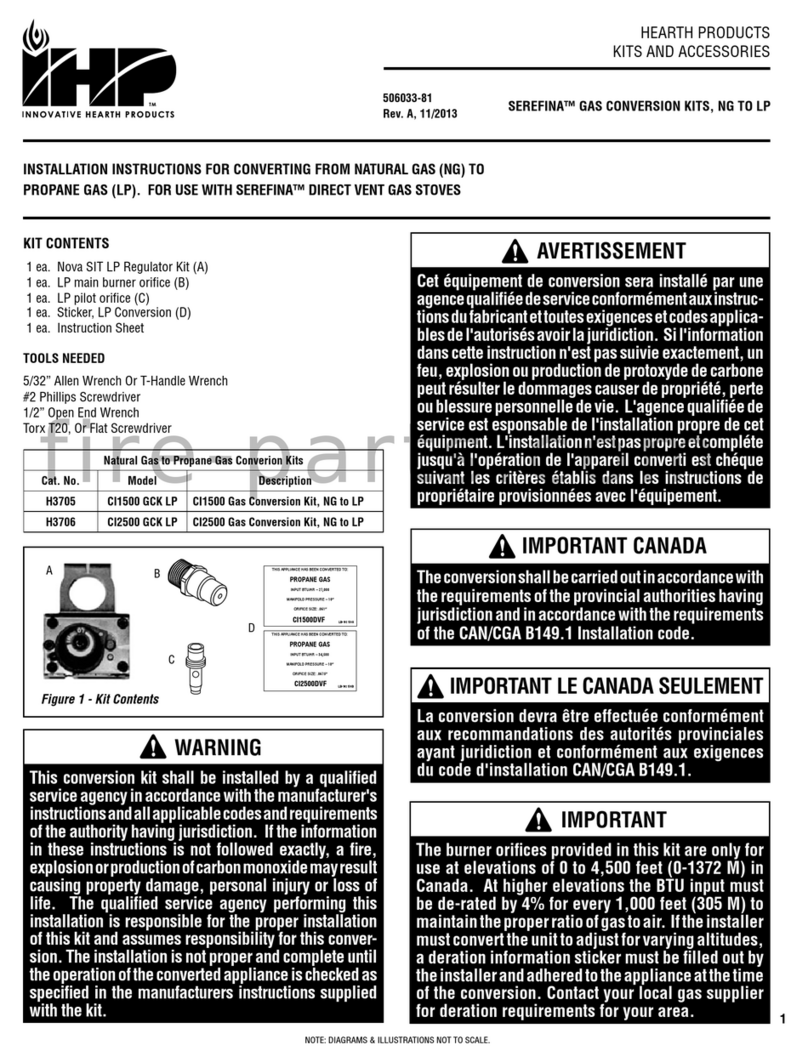

PCBE-325 GAS CONVERSION KIT, ELECTRONIC, NATURAL GAS TO PROPANE/LP GAS

[FOR USE WITH APPLIANCE MODELS BRT2332 AND BRT2532]

PCBE-325 GAS CONVERSION KIT

NATURAL GAS TO PROPANE/LP GAS

P/N 127192-01

Rev. B, 03/2017

HEARTH PRODUCTS

KITS AND ACCESSORIES

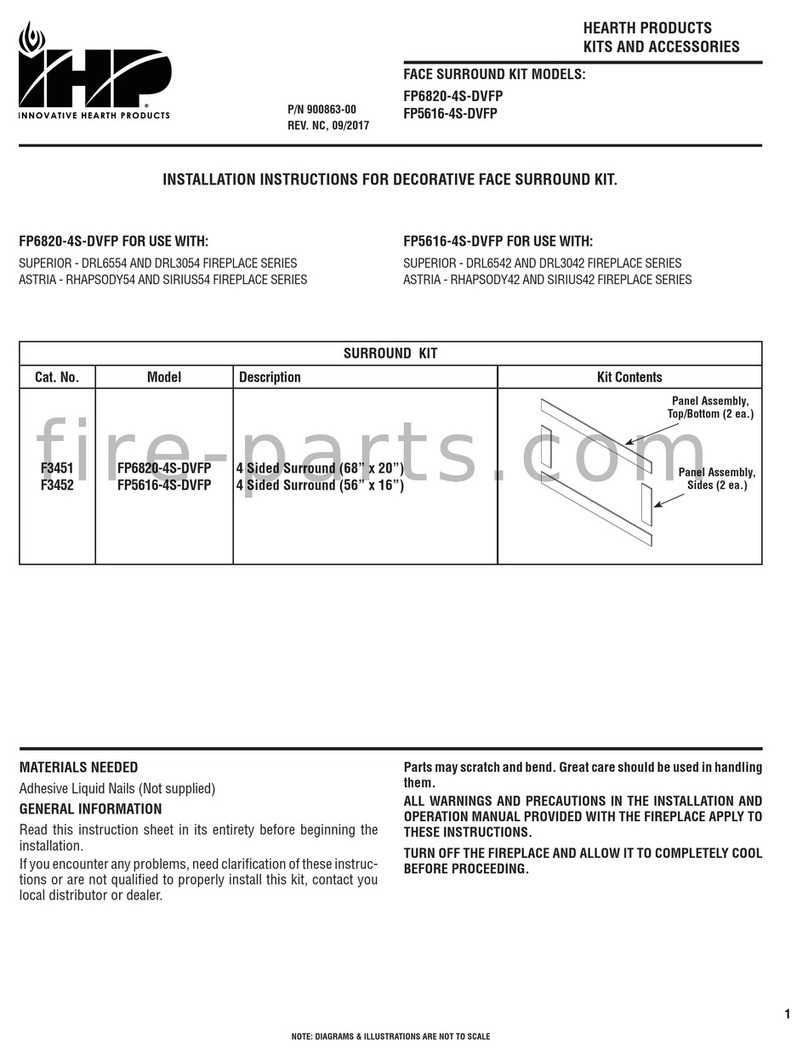

Cat. No. Model Description

F1121 PCBE-325 Gas Conversion NG to LP

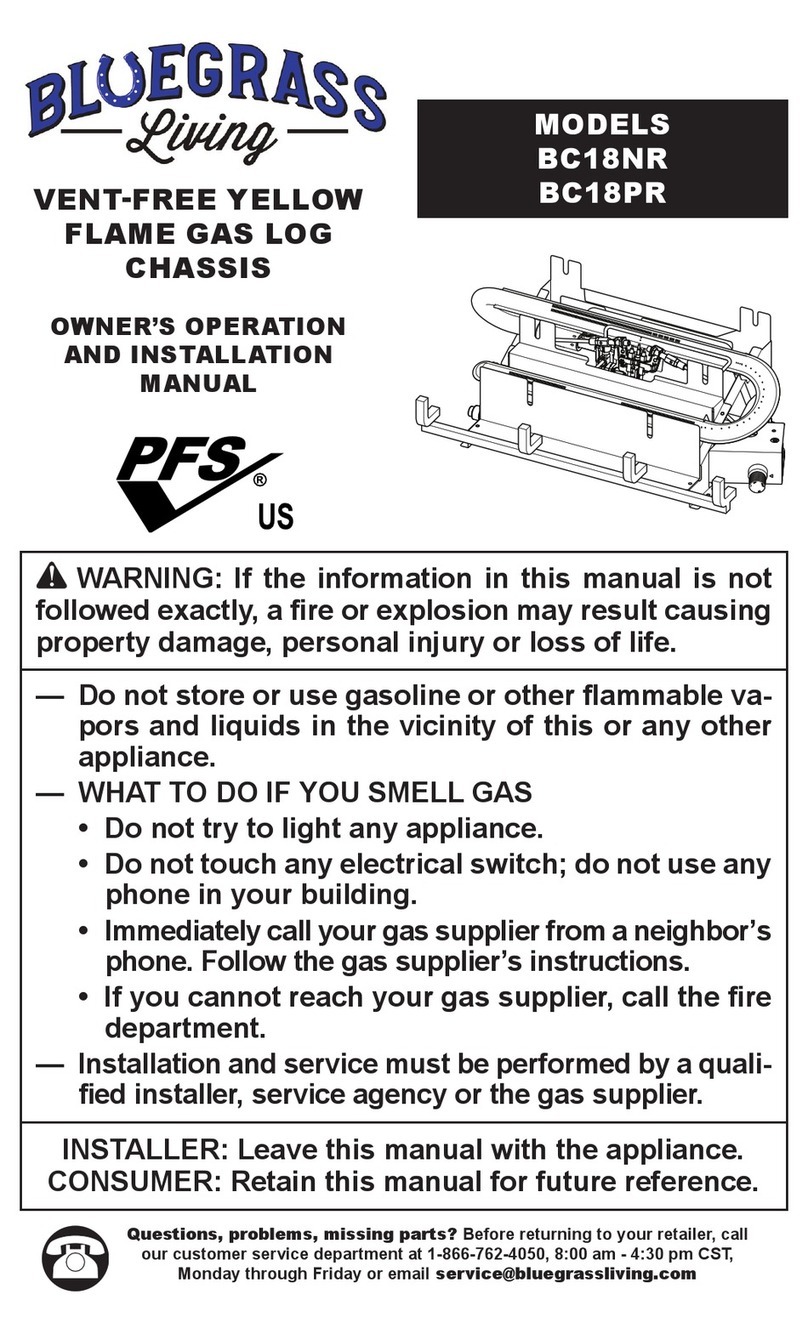

WARNING

This conversion kit shall be installed by a qualified

service agency in accordance with the manufac-

turer's instructions and all applicable codes and

requirements of the authority having jurisdiction. If

the information in these instructions is not followed

exactly, a fire, explosion or production of carbon

monoxide may result causing property damage,

personal injury or loss of life. The qualified service

agency performing this installation is responsible

for the proper installation of this kit and assumes

responsibility for this conversion. The installation

is not proper and complete until the operation of the

converted appliance is checked as specified in the

manufacturers instructions supplied with the kit.

IMPORTANT LE CANADA SEULEMENT

La conversion devra être effectuée conformément aux

recommandations des autorités provinciales ayant

juridiction et conformément aux exigences du code

d'installation CAN/CSA B149.1.

IMPORTANT CANADA

The conversion shall be carried out in accordance with

the requirements of the provincial authorities having

jurisdiction and in accordance with the requirements

of the CAN/CSA B149.1 Installation code.

AVERTISSEMENT

Cet équipement de conversion sera installé par

une agence qualifiée de service conformément aux

instructions du fabricant et toutes exigences et codes

applicables de l'autorisés avoir la juridiction. Si

l'information dans cette instruction n'est pas suivie

exactement, un feu, explosion ou production de

protoxyde de carbone peut résulter le dommages

causerdepropriété,perteoublessurepersonnellede

vie. L'agence qualifiée de service est esponsable de

l'installation propre de cet équipment. L'installation

n'est pas propre et compléte jusqu'à l'opération de

l'appareil converti est chéque suivant les critères

établis dans les instructions de propriétaire provi-

sionnées avec l'équipement.

1

fire-parts.com