IMER KOINE 4 Guide

PLASTERING MACHINE

Operating,maintenance,spare parts manual

3223425 R18 - 2018/09

KOINE 4/5

2

IMER INTERNATIONAL S.p.A.

INTONACATRICI IMER

Special attention must be given to warnings with this symbol:

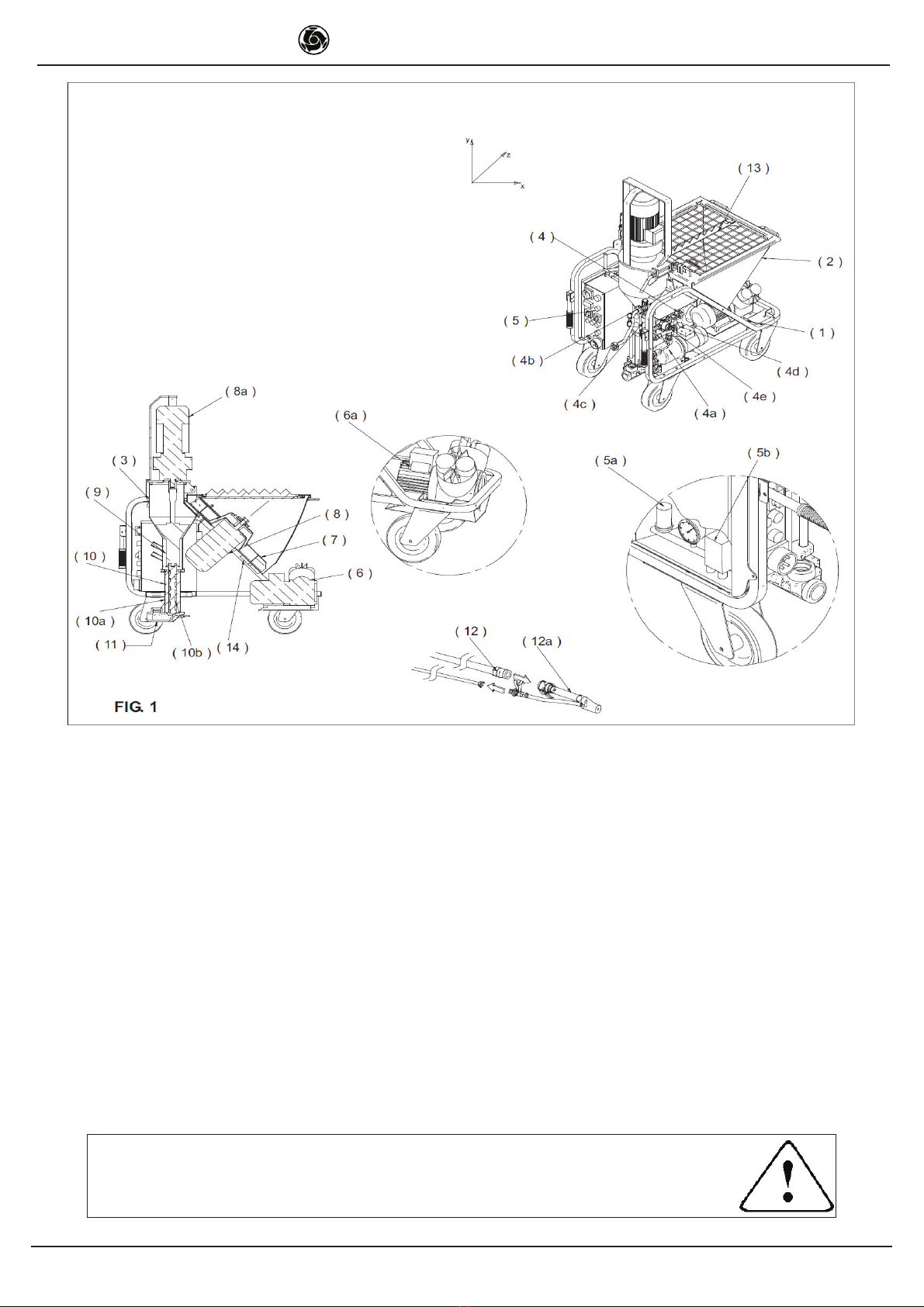

FIG. 1

ENGLISH

( 1 ) WHEELED FRAME

( 2 ) HOPPER

( 3 ) MIXING CHAMBER

( 4 ) WATER CIRCUIT

( 4a ) WATER PUMP

( 4b ) MICROMETRIC VALVE

( 4c ) FLOW METER

( 4d ) WATER PRESSURE SWITCH

( 4e ) PRESSURE REDUCER

( 5 ) ELECTRICAL PANEL

( 5a ) COMPRESSOR PRESSURE

SWITCH

( 5b ) MACHINE PRESSURE SWITCH

( 6 ) DIAPHRAGM COMPRESSOR

( 6a ) RELIEF VALVE COMPRESSOR

( 7 ) CELL WHEEL

( 8 ) CELL WHEEL GEARMOTOR

( 8a ) MORTAR PUMP GEARMOTOR

( 9 ) MIXER

( 10 ) MORTAR PUMP

( 10a ) STATOR

( 10b ) CAM SCREW

( 11 ) MANIFOLD

( 12 ) MATERIAL DELIVERY HOSE

( 12a ) SPRAY JET

( 13 ) GRILLE WITH SACK SPLITTER

( 14 ) HOPPER WATER OUTLET PLUG

3

IMER INTERNATIONAL S.p.A.

KOINE 4/5

Dear Customer,

compliments on your purchase of this IMER plaster mixer, the re-

VXOWRIORQJVWDQGLQJH[SHULHQFHLQWKH¿HOGDQGIHDWXUHVPD[LPXP

UHOLDELOLW\DQGLQQRYDWLYHWHFKQLFDOVROXWLRQV

- WORKING IN SAFETY.

To ensure complete safety, read all the instructions in this

manual carefully.

This OPERATION AND MAINTENANCE manual must be kept

by the Site Manager and be always available for consultation.

The manual is considered part of the machine and must be stored

for future reference (EN ISO 12100) through to scrapping of the

machine itself. If the manual is lost or damaged, a replacement

copy can be ordered from the manufacturer.

The manual contains the EC declaration of conformity 2006/42/EC)

important information on construction site procedures, installation,

operation, maintenance and requests for spare parts. Neverthe-

less, the user must both have adequate experience and knowledge

of the machine prior to use: the user should be trained by a person

totally familiar with the operation and use of this machine.

In order to ensure operator safety, safe operation and long service

life, all instructions in this manual must be observed, together with

the requirements of current legislation governing work safety (use

of safety footwear and adequate clothing, use of helmets, gloves,

goggles etc.).

- Make sure that all signs are legible.

1HYHUPDNHDQ\PRGL¿FDWLRQVWRWKHPHWDOVWUXFWXUH

or plastering machine systems

IMER INTERNATIONAL accepts no responsibility in the event

of failure to comply with laws governing the use of this type of

equipment, with particular reference to: improper use, incorrect

SRZHUVXSSO\ODFNRIPDLQWHQDQFHXQDXWKRULVHGPRGL¿FDWLRQDQG

failure to comply, either wholly or partially, with the instructions set

out in this manual.

IMER INTERNATIONAL reserves the right to modify the cha-

racteristics of the plastering machine and/or contents of this

manual, without the obligation to update the previous machine

and/or manuals.

1. TECHNICAL DATA

7DEOH SURYLGHV WKH WHFKQLFDO VSHFL¿FDWLRQV RI WKH SODVWHULQJ

PDFKLQHZLWKUHIHUHQFHWR¿JXUH

2. DESIGN STANDARDS

The plastering machines have been designed and constructed

DFFRUGLQJWRWKHVWDQGDUGVVSHFL¿HGLQWDEOH

3. NOISE EMISSION LEVEL

Table 1 shows the sound pressure levels of the plastering machine

measured at the ear of the operator (LpA at 1m) and noise emission

levels in the environment (power LWA) measured according to EN

ISO 3744 (2000/14/CE).

4. DESCRIPTION OF PLASTERING MACHINE OPERATION

- The plastering machine is designed for use in building

sites, for mixing and pumping all mixed mortars declared as

compatible with this type of machine by the material manu-

facturers: gypsum based plasters, anhydrite based plasters,

lime/cement based plasters, reverse insulation plasters,

grouting mortar etc.

4.1 PLASTERING MACHINE DESCRIPTION (Fig. 1)

The plastering machine comprises a wheeled frame (ref.1), which

supports a hopper (ref.2), a mixing chamber (ref.3), a water circuit

(ref.4) complete with self-priming pump (ref.4a), an electrical panel

(ref.5), and a diaphragm compressor (ref.6).

The pre-mixed dry material is poured in to the hopper, in which

a cell-wheel-dispenser (ref.7), activated by a gearmotor (ref.8),

moves the material inside the mixing chamber. The mixing cham-

ber contains

a mixer (ref.9), activated by a gearmotor (ref.8a), which mixes the

material with water delivered to the chamber by the water pump.

7KHZDWHUÀRZUDWHLVUHJXODWHGE\PHDQVRIDPLFURPHWULFYDOYH

UHIEDQGGLVSOD\HGYLDDÀRZPHWHUUHIF7KHPL[HUGULYHV

a helical rotor pump (ref.10) which conveys the material via a

rubber hose (ref.12) to the spray jet (ref.12a). Ther air pumped

by the compressor is also delivered to the jet to enable spray

application onto the walls.

5. OPERATION SAFETY

- Before using the plastering machine, ensure that it is

¿WWHGZLWKDOOVDIHW\GHYLFHV

- Never insert parts of the body and/or tools in the hopper

or mixing chamber during operation.

All current standards governing accident prevention and safety

devices must be observed in the workplace.

Take care when handling sacks of material to avoid dispersion of

dust with inhalation of the latter; if this is not possible masks must

be worn to protect the mouth and nose.

- Never use the machine in areas subject to the risk of

H[SORVLRQ¿UHVRULQXQGHUJURXQGLQVWDOODWLRQV

The plastering machine is not equipped with a lighting system

DQGWKHUHIRUHWKHZRUNSODFHPXVWEH¿WWHGZLWKDGHTXDWHOLJKWLQJ

The power lines must be laid to prevent any possible damage.

Never place the plastering machine on electric power cables.

Ensure that the electrical connection is protected against the risk

of water penetration in connectors. Use exclusively connectors

and couplings equipped with water spray protection.

- Never use inadequate or provisional electric lines; if in doubt

consult specialist personnel for assistance.

- Repairs to the electrical circuit must be performed exclusively by

specialised personnel. Disconnect the machine from the power

supply before performing maintenance or repairs.

-Avoid contact of electric wires with movable and/or moving parts

of the machine to avoid injury from contact with live metal parts.

6. ELECTRICAL SAFETY

The G.I.5 plastering machine is constructed according to standard

EN 60204-1, with protection against water sprays and protection

against overload and power failure.

The plastering machine must be connected to the earthing circuit.

TRANSLATED INSTRUCTIONS

4

IMER INTERNATIONAL S.p.A.

KOINE 4/5

7. MECHANICAL SAFETY

The hazardous points on the IMER plastering machine are

protected by means of suitable safety devices, which must remain

¿WWHGDWDOOWLPHVDQGNHSWLQSHUIHFWFRQGLWLRQVXFKDVWKHHOHFWULF

motor cooling fan guard and the grille on the hopper to prevent

contact with the cell wheel.

Also opening of the mixing chamber, either via the motor support

ÀDQJHRUWKHFRPSOHWHPL[LQJFKDPEHUVKXWVGRZQWKHURWDU\SDUWV

RIWKHPDFKLQHWKDQNVWRDVSHFL¿FVDIHW\PLFURVZLWFK

8. TRANSPORT

- Caution! Before moving the plastering machine, always

detach the power plug.

Before moving the plastering machine the water delivery hose and

material delivery line must be removed.

Only a minimal amount of the material should be in the hopper

when handling.

Release the wheel by means of the brake and move the mixer by

PHDQVRIWKHKDQGOHV¿J

FIG.2

- Caution! Before lifting the plastering machine, always

disassemble the compressor for separate transport.

- Caution! Before lifting the machine, always check that

DOOPDFKLQHFRPSRQHQWVDUHFRUUHFWO\VHFXUHGDQG¿WWHGLQ

place.

7ROLIWWKHPDFKLQHXVHWKHVSHFL¿FDWWDFKPHQWULQJV¿J

FIG.3

- Caution! Lift with care to avoid hazardous oscillations

&DXWLRQ1HYHUXVHSRLQWVRWKHUWKDQDVVSHFL¿HGLQ

¿JXUHWROLIWWKHPDFKLQHDQGLQSDUWLFXODUGRQRWKRRNXS

lifting equipment to the gearmotor guard.

Use lifting equipment suited to the overall weight of the machine

indicated in table 1.

To facilitate transport, the machine can be disassembled as

VKRZQLQ¿J

.

FIG.4

7KHZHLJKWRIWKHVXEXQLWVVKRZQLQ¿JDUHVSHFL¿HGLQWDEOH

9. INSTALLATION

3RVLWLRQWKHSODVWHULQJPDFKLQHRQDÀDWVXUIDFHLQDQDUHDZKHUH

it does not constitute an obstruction either during use or cleaning

at the end of the work shift and where a minimum quantity of

pipelines is required.

Secure the machine in place by means of the wheel brake (ref.5

¿J

10. CONNECTIONS

10.1 ELECTRICAL CONNECTION

- Ensure that the power supply voltage, mains frequency

and electrical connection (socket, fuses, cable) correspond

WRVSHFL¿FDWLRQVLQWDEOH

7KH HOHFWULFDO SRZHU OLQH PXVW EH ¿WWHG ZLWK SURWHFWLRQ DJDLQVW

current overload (e.g. by means of fuses or a thermal magnetic

cut-out) and with current dispersion to earth (e.g. with a differential

circuit breaker). The electric cable wire size must take into account

the operating currents and length of the line to avoid excessive

voltage drops.

Avoid use of extension leads wound on drums. The power cable

must be suitable for frequent movements and with an abrasion

resistant sheath (e.g. type H07RN-F).

Before connecting the plastering machine to the electrical mains,

HQVXUHWKDWDOOVDIHW\GHYLFHVDUH¿WWHGDQGDUHLQSHUIHFWFRQGL-

tion, and check in particular that the hopper grille is secured in

place, that the extension in good condition and that the plugs and

sockets are not wet.

Connect the plastering machine socket on the electrical panel to

WKHPDLQV¿J

FIG.5

5

IMER INTERNATIONAL S.p.A.

KOINE 4/5

10.2 WATER CONNECTION

&RQQHFWWKHZDWHUKRVHWDEOHWRWKHZDWHUPDLQV¿J

7KHZDWHUPDLQVPXVWJXDUDQWHHDPLQLPXPÀRZUDWHRI

20l/min.

2WKHUZLVHDWDQNRIVXLWDEOHFDSDFLW\OPXVWEH¿WWHGZLWK

clean water, to be kept full at all times, and from which water can

be taken by means of the self-priming pump supplied with the

machine. In this case the hose must have a minimum diameter

RIDPD[LPXPOHQJWKRIPSUHIHUDEO\DIRRW¿OWHUDQGPXVW

not be subject to deformation during use.

&DXWLRQ7KH¿UVWWLPHWKHZDWHUSXPS

is connected to the tank, it must be activated by manually

¿OOLQJWKHLQWDNHOLQH

The same operation must be repeated each time the circuit is

drained, or after a prolonged period of disuse.

FIG.6

10.4 AIR CONNECTION

&RQQHFWWKHDLUKRVHWRWKHPDFKLQHSDQHODQGVSUD\MHW¿J

FIG.7

11. START-UP

&ORVHWKHDLUYDOYHUHIDVXSSO\LQJWKHVSUD\MHW¿J

Open the micrometric valve (ref.8) virtually fully.

Turn the main switch/inverter (ref.1a) to position 1 or 2: in the

correct position the blue “phase correct” lamp illuminates (ref.1g).

Check that the water pressure gauge (ref.11) indicates a minimum

pressure of 3.5 bar and that the green “no water pressure” lamp

(ref.1i) is off. Otherwise, activate the pump by means of the water

pump switch (ref.1f). Press the water supplement pushbutton

(ref.1d) for 3-4 seconds.

Start the pump by means of the start pushbutton (ref.1c):

the lamp on the start/stop pushbutton illuminates and the mortar

pump starts up for a few seconds.

Open the spray jet air valve: the machine starts up. Check that the

water pressure does not fall below 2.5 bar; otherwise activate the

ZDWHUSXPS8VHWKHPLFURPHWULFYDOYHWRUHJXODWHWKHZDWHUÀRZ

UDWHGLVSOD\HGRQWKHÀRZPHWHUUHIZLWKUHVSHFWWR

- 800l/min if using gypsum based materials (pump D 6-3).

- 500l/min if using cement based materials (pump D 6-3).

Start the cell wheel by means of the relative switch (ref.1e) and

then stop it.

Close the air valve.

Fill the hopper with dry materials.

Open the air valve of the jet.Activate and deactivate the cell wheel

3 or 4 times by means of the relative switch

(2 -3 seconds operation, 2-3 seconds stopped) and then switch

on permanently. Regulate the water to obtain the consistency as

recommended by the material manufacturer. Close the air valve to

the spray gun. Check the material hoses to ensure perfect condi-

WLRQWKDWFRXSOLQJVDUHLQWDFWDQGWKHUHODWLYHVHDOVDUH¿WWHGDQG

SRXUDSSUR[OLWUHVRIJURXWLQWKH¿UVWVHFWLRQDQGWKHQFRQQHFW

them to the delivery manifold (ref.10) and spray jet. Check that

the cam levers ( A ) of the couplings have been tightened correctly

and that the seal

%LV¿WWHGDVVKRZQLQ¿J

FIG.8

FIG8

FIG.9

Start the machine: when the correct consistency of material is

delivered from the jet normal operation can be started.

The machine starts and stops by opening and closing the air

supply to the spray jet.

7KHPDFKLQHLV¿WWHG ZLWK SURWHFWLRQDJDLQVWSRZHU IDLOXUH DQG

water pressure failure: if one of these occur, press the start pu-

shbutton to resume operation.

To stop the machine in the event of an emergency, press the red

emergency pushbutton (ref.1b) to shut down the machine - all

moving parts are shut down - and then turn the main switch to 0

and remove the electric power plug from the socket (ref.1l).

6

IMER INTERNATIONAL S.p.A.

KOINE 4/5

THERMAL CUTOUT PROTECTION:

- The electric motors are protected against overload by

thermal magnetic cutouts, the activation of which is displayed

by illumination of the red lamp (ref.1h). In this case, after the

PRWRUVKDYHFRROHGWKHVSHFL¿FSHUVRQQHOVKRXOGRSHQWKH

electrical panel and reset the cutouts.

For the mortar pump motor (ref.12) there is an additional

safety protection: a thermal sensor shuts down the machine

in the event of a motor temperature overload.

12. OPERATION

- The hopper safety grille must be ¿WWHG DQG VHFXUHG

at all times.

Never place materials other than premixed dry materials in

the hopper.

- Opening of the mixing chamber causes shutdown of the

PDFKLQHPRYLQJSDUWV¿J)LUVWFORVHWKHPL[LQJFKDPEHU

and press the start pushbutton to start the machine.

:HDUVSHFL¿HGSURWHFWLYHGHYLFHVEHIRUHZRUNLQJRQ

the machine

FIG.11

FIG.10

Regulate the water to obtain the required consistency.

'LIIHUHQWGLDPHWHUVRIGHÀHFWRUDUHDYDLODEOHPP

WKHVPDOOHUGHÀHFWRUVHQDEOHLPSURYHGQHEXOLVDWLRQDQGWKHODUJHU

ones are more suited to materials with a larger particle size.

)RUVWDQGDUGSODVWHULQJPDWHULDOVWKHGHÀHFWRUZLWKPPKROH

(ref.9b) is used.

However, it is important to measure the distance of the nozzle

(ref.9c) from the outlet so that it is the same as the diameter of

WKHGHÀHFWRU¿J

If no water is delivered, the machine shuts down.

Before restarting the machine, identify the cause of the problem:

YDOYHFORVHGGHOLYHU\KRVHEHQWWDQNHPSW\FORJJHG¿OWHUUHI

Interruptions exceeding 30min should be avoided.

7

IMER INTERNATIONAL S.p.A.

KOINE 4/5

Prolonged shutdown can cause clogging in the material delivery

lines: in this case no material is delivered from the jet and the

pressure gauge (ref.3) indicates a higher pressure than the normal

working value.

Shut down the machine by means of the stop pushbutton (ref.1d),

position the cell wheel switch (ref.1e) to 0 and the main switch to

the opposite settings to the normal work position (the blue lamp

turns off) and press the inversion pushbutton for a few seconds

(ref.1l): the mortar pump motor rotates in the opposite direction

(the water solenoid valve (ref.13) stays closed) and the pipelines

are depressurised (the pressure gauge reads 0 bar).

Locate the point of clogging in the hose

and remove by tapping the pipeline with a mallet.

- If necessary, disconnect the jet or open the pipeline

couplings, checking previously if any residual pressure is

present.

The material pressure gauge must indicate 0 bar and the

SLSHOLQHVH[FOXGLQJWKHFORJJHGVHFWLRQVPXVWEHÀH[LEOH

The personnel assigned for this task must be specially trained

in these procedures.

In the event of any doubt as to the presence of residual pres-

sure, never open the couplings.

Reconnect the pipelines and spray jet, set the main switch to the

correct position (the blue lamp illuminates) and restart the machine.

- Do not move the machine with the hopper full.

If the material delivered is alternately hard and soft this may indica-

te a worn pump. To replace the pump, proceed as follows: release

the handle on the left and open the mixing chamber. Insert the

tube wrench on the end of the mixer and unscrew until the screw

inside the stator is released. Close the mixing chamber, tilt and

lock in the lifted position, remove the material delivery manifold

DQG¿WDQHZVFUHZVWDWRUXQLW¿J

FIG.13

To insert the screw in the stator, use the lubricant spray available

from IMER. Never use mineral oil or grease for screw assembly

as this may damage the stator. Avoid all types of benzene.

In the case of a power failure during operationclean the machine

and pipelines immediately (see para.13). Also disassemble the

pump, remove the screw from the stator and clean. On completion

reassemble all components.

13. MACHINE SHUTDOWN AND CLEANING

At the end of work, stop the cell wheel and continue pumping until

the material delivery pipelines are empty.

Stop the machine by means of the pushbutton and set the main

switch to 0.

Open the jet valve, detach the jet and clean thoroughly, cleaning

WKHQR]]OHZLWKWKHVSHFLDOWRROVXSSOLHG¿J

FIG.14

- Before disconnecting the jet or pipelines, ensure that

there is no residual pressure.

Disconnect the material pipelines from the delivery manifold.

Detach the quick connector with safety device (ref.14) and open

WKHPL[LQJFKDPEHU¿J

FIG.15

Remove the mixer and clean. Clean the mixing zone with a brush.

,QVHUWWKHVFUDSHUUHIDVVKRZQLQ¿JFORVHWKHPL[LQJ

chamber, turn the main switch to the correct position (blue lamp

ON) and then press the start pushbutton. Leave running for

5-10 seconds, until the mixing chamber is completely clean.

FIG.16

8

IMER INTERNATIONAL S.p.A.

KOINE 4/5

Stop the machine by means of the stop pushbutton, remove the

VFUDSHUDQGUH¿WWKHFOHDQPL[HU

Proceed with pipeline cleaning. Insert a washing sponge (ref.16)

at the start of the pipeline, connect the material delivery hose to

the mortar hose-water hose coupling (ref.17), and then connect

the latter to the auxiliary water valve. Insert the water pump and

open the auxiliary water valve until the washing sponge comes

RXWIURPWKHRWKHUHQG¿J

If using pipelines with a different diameter for cleaning, use a

suitably sized sponge. Repeat the operation until the pipeline is

perfectly clean.

At this point, on completion of machine cleaning, turn off the

main switch, disconnect the power plug, close the water delivery

valve, open the auxiliary valve for a few seconds and detach the

delivery hose.

If there is any risk of freezing, open the three valves (ref.18) as

VKRZQLQ¿JDQGGUDLQDOOZDWHUIURPWKHFLUFXLW

Remember to reclose the valves before restarting the machine.

If the machine is not to be used for several days, empty the hopper

completely, opening also the drain plug (ref.5, see EXPLODED

MACHINE DRAWING).

Also remove the cell wheel.

- Before opening the drain plug or the grille, ensure that

the main switch is turned to 0 and the plug is disconnected

from the power supply

14. MAINTENANCE

- Maintenance must be performed by adequately trained

personnel, after switching off the machine, disconnecting it

from the power supply and emptying the hopper.

&KHFNGDLO\WKDWWKHZDWHU¿OWHULVFOHDQ

&KHFNZHHNO\WKDWWKHFRPSUHVVRUDLU¿OWHULVFOHDQ,IGHWHULRUD-

ted, replace.

Check weekly that the mixer is in good condition and replace if

necessary.

Check weekly that the motor connection is in good condition and

replace if necessary.

Check weekly that the electric motors are free of dust and dirt and

if necessary clean using compressed air.

Check weekly that the plug and socket contacts are clean, dry

and rust free.

Every six months arrange for an inspection of the machine by a

technician authorised by IMER or authorised IMER dealer.

- Spent oil is a special waste. Therefore it must be dispo-

sed of according to current legislation.

- Always keep notices and symbols on the machine

legible.

15. REPAIRS

- Never start up the plastering machine during repairs.

Repairs to the electrical installation must be performed exclusively

by specialised personnel.

Use exclusively original IMER spare parts, which must not

EHPRGL¿HGLQDQ\ZD\

- If any guards are removed for repairs, ensure they are

UH¿WWHGFRUUHFWO\DWWKHHQGRIZRUN

FIG.18

16. SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials

with silica in their composition my give off dut or mists cintainig crystalli-

ne silica. Silica is a basic component of sand, quartz, brick clay, granite

and numerous other minerals and rocks. Repeated and/or substantial

inhalation of airborne crystalline silica can cause serious or fatal respira-

tory diseases, including silicosis. In addition, California and some other

authorities have listed respirable crystallinesilica as a substance known

to cause cancer. Whwn cutting such materials, always follow respiratory

precautions.

Use appropriate NIOSH-approved respiratory protection where dust

hazard may occur. Paper masks or surgical masks without a NIOSH

approval number are not recommended because they do little to protect

the worker. For more information about respirator programs, including

what respirators have received NIOSH approval as safe and effective,

please visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

Observe OSHA regulations for respirator use (29 C:F.R. § 1910.134).

Visit http://www.osha.gov for more information.

California proposition 65 message

Some dust created by power sanding, sawing, grinding, drilling, and

other construction activities contain chemicals know (to the State of Ca-

lifornia) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

-Lead, from lead-based paints

-Crystalline silica, from bricks and cement and other masonry products

-Arsenic and chromium, from chemically treated lumber

For further information , consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

http://www.P65warnings.ca.gov

Your risk from these exposures varies depending on how often you do

this typer of work. To reduce your exposure to these chemicals, work in

a well-ventilated area, and work with approved safety equipment, such

DVGXVWPDVNVWKDWDUHVSHFLDOO\GHVLJQHGWR¿OWHURXWPLFURVFRSLFSDU-

ticles. Where use of a dust extraction device is possible, it should be

used. To achieve a high level oof dust collection, use an industrial HEPA

vacuum cleaner. Observe OSHA 29 CFR part 1926.57 and 1926.103

9

IMER INTERNATIONAL S.p.A.

KOINE 4/5

10

IMER INTERNATIONAL S.p.A.

KOINE 4/5

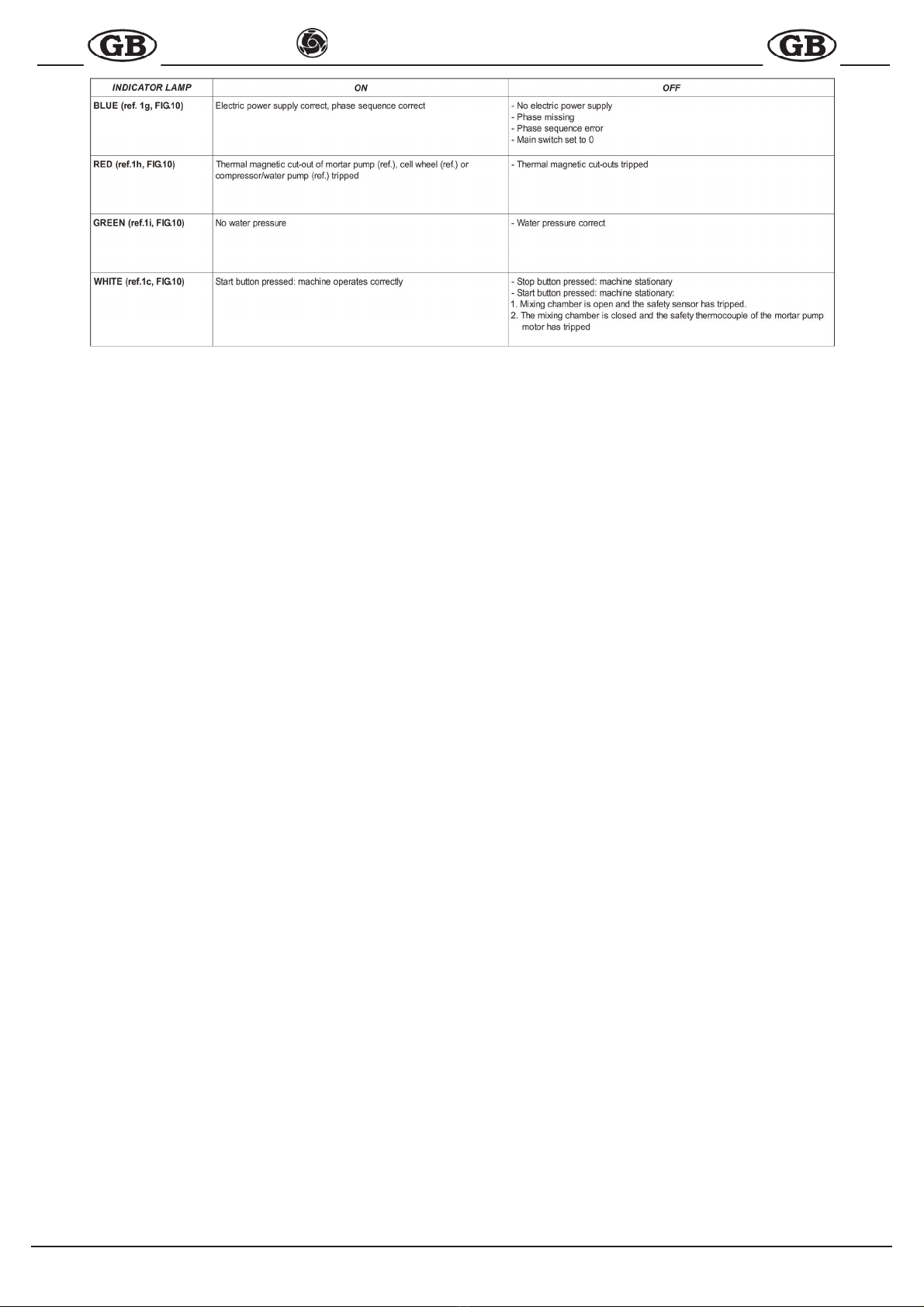

INDICATOR LAMP TABLE

Other manuals for KOINE 4

1

This manual suits for next models

1

Table of contents

Other IMER Construction Equipment manuals