INIM Electronics Moon 700 Series User manual

Gas detector Moon series 700 - Installation manual.

File: s.700UM1_IT.pdf

INIM Electronics Srl reserves the right to make changes to the product and

the manuals without any notice.

Rev. 04 10.2017

Page 1/14

Gas detector series Industrial

Installation Manual

Gas detector Moon-2 series 700 - Installation manual.

File: Moon-2 UM1_IT.pdf

Micromac reserves the right to make changes to the product and the manuals

without any notice.

Rev. 04 14 2017

Page 2/14

These instructions shall be used by qualified service personnel only,

who have been duly trained to install and maintain Gas detection

systems.

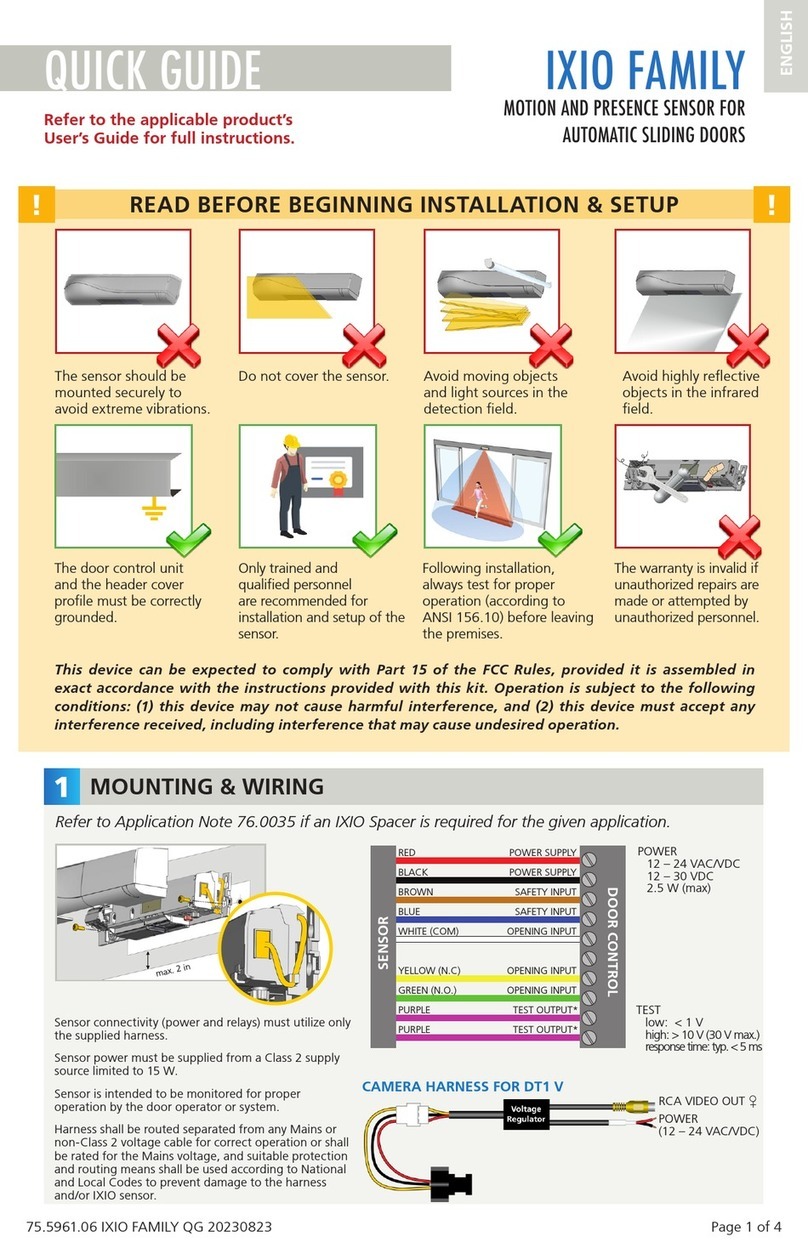

WARNINGS

Valid for all variants of IP and ATEX Gas detectors

Do not install and connect the gas detector without carefully reading these

instructions. All operations must be executed by skilled personnel who are aware of

the regulations and has attended a technical training course on products included in

this manual.

The housing must be earthed (grounded).

Keep the sensor away from gas substances or solvents such as silicone and

derivatives, acetone, all types of paints, alcohol & derivatives, cleaning solvents,

turpentine, bleach, etc. These agents could damage the sensitive part of the sensor

or permanently change the original setting. Strictly avoid to test the sensors with

lighters or generic spray cans.

When the sensor is outdoor installed, it’s necessary to put an adequate cover over

the sensor to avoid being directly wet by rain or snow.

Do not install the sensor closed to vents, high speed air or vortexes.

During the installation or maintenance of ATEX gas detectors, before opening the

housing, make sure that the power is OFF (either 24Vdc or current loop) and that

the application area is safe. Otherwise it’s forbidden to open the sensor and

execute connections.

Do not disconnect any connectors or plug-in cards when the sensor is powered up.

When the installation is completed, it’s necessary to execute the electrical tests on

the sensors by using the proper software, working with the simulation functions,

generating pre-alarm, alarm and fault conditions and checking the exact match in

the control panel or in any other device connected to the sensors

For ATEX gas detectors it’s mandatory to read carefully the safety instructions

contained in the package.

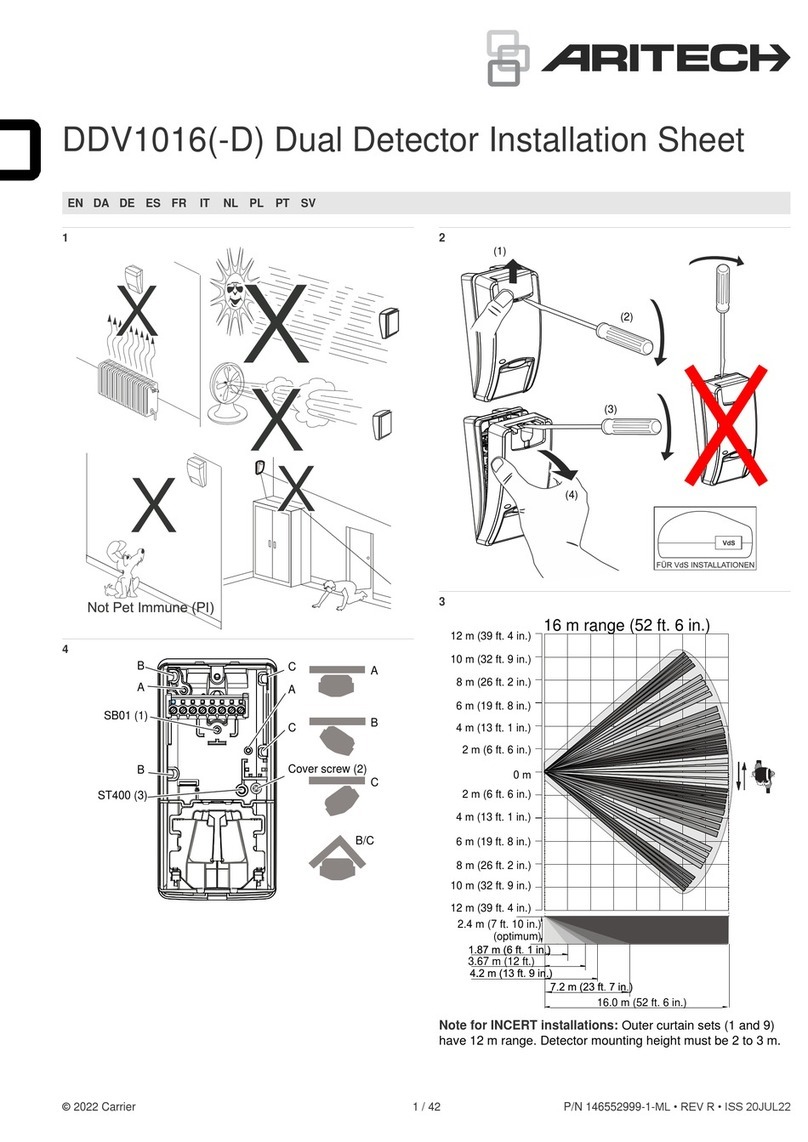

The Gas detector must be installed vertically with its nose facing down (see

pictures).

Do not unplug the connector of the sensitive element when it’s powered and do not

power the sensor when the head is not available

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 3/14

The installation height is determined by the type of gas to be detected. Here below

there are some examples; in case the type of gas is not included in this list, please

check the specific gravity to avoid installation errors.

Examples:

Heavy gases: about 30 cm from the ground (eg. Propane, gasoline vapors etc.)

Light gases: about 30 cm from the ceiling (eg. Methane, Hydrogen, etc)

The Oxygen and Carbon Monoxide gas detectors have to be installed mainly at ca.

1,60 cm from the ground.

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 4/14

NOTES NOT SUBJECT TO REVIEW

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

------------------------------------------------------------------------------------------------------------------------

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 5/14

Gas detector Moon series - Overview

The new generation of gas detectors Moon series is available with 5 different sensing

elements, in order to provide a very large range of Gas detection applications.

The sensor can be combined with 6 different Communication Interfaces that can be

selected according to the installation needs. Details and diagrams in the next pages.

The detector has been designed to give to the installer the possibility to check the sensor

parameters, set and change the sensor element, provide maintenance service directly on-

site, through a dedicated software application (Level 1 and Level 2).

L1 visualization

Production year and serial number, sensor type, sensor code, unit of

measure, gas head FW version, base board FW version.

Indication of alarm and prealarm status, fault status and fault type.

Prealarm and alarm threshold

Prealarm and alarm filters

4-20mA working range

Initialization delay

Sensor life (working hours)

Alarms number (only real alarms occurred during sensor life are counted, not

software simulation).

Level 2

Password protected: it is possible set the sensor, with the support of calibrated gas

cylinders, without any electronic adjustment trough trimmers or jumper, but easily

trough the software interface. Moreover it is possible finalize the sensor element

(head) substitution, even by software. This function is conform to the international

technical norms in order to protect the detector from external sabotage or setting

modification by not authorized personal.

The head substitution can be done only with a new one (same item). A different

head will generate a failure into the detector.

L2 Parameters editing

Prealarm and alarm threshold

Prealarm and alarm filters

4-20mA working range

Initialization delay

Sensor element (head) substitution

Calibration

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 6/14

Gas detector Moon series - G7(AP) E7(AD) product range

Description

Industrial gas detectors, available with IP55 metal housing or ATEX II 2G Ex-d IIC T6

housing. The detector is combined with two boards: the first card controls the sensing

element, and depends to the detected Gas type; the second one controls the communication

to the control device (see the table below) and it is available either for connection to specific

panels or for connection to normal electrical cabinets and PLC.

Sensors for automatic gas detection are generally suitable for explosion risks,

Hydrocarbons (L.I.E. detection), toxicity Ammonia, Carbon Monoxide (ppm detection) and

Oxygen control (% detection).

Code

Description

Page

G7-RL

3 relays connection

09

G7-AS

Conventional and Addressed Modules

10

G7-42

4-20mA connection

11

G7-LE

Loop Panels with Enea protocol

12

Board 1

Board 2

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 7/14

Gas detector Moon series - Technical Features

General Features

Power Supply: 12/24Vdc

Semiconductor sensors: Max 50/80 mA (StBy/Alarm)

Catalytic sensors: Max 70/100 mA (StBy/Alarm)

Elettrochemical cell sensors: Max 30/60 mA (StBy/Alarm)

Operating temperature: 0 to 40 °C with compensation measurement

Humidity Up to 90% relative, non-condensing

Max air speed 10 m/sec

Standard Thresholds

L.I.E.: 15% prealarm and 30% alarm

P.P.M.: 100ppm prealarm and 200ppm alarm

Oxygen (defect): 18% prealarm and 15% alarm

Oxygen (excess): 24% prealarm and 27% alarm

Mechanical Features

G7 metal housing IP55 ADFT

Dim. (HxWxD) 141x100x60mm

Weight 370gr

E7 explosion proof housing ATEX II 2G Ex-d IIC T6

Dim. (HxWxD) 170x90x78,50

Weight 1Kg

Electronic Base Board

LEDs Description

LD1 yellow color, failure.

LD2 green color, power supply presence.

LD3 red color, prealarm, Gas presence equal or higher to the prealarm threshold.

LD4 red color, alarm, Gas presence equal or higher to the alarm threshold

J1 Terminal board

1 Negative

2 Positive 12/24 Vdc

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 8/14

LIFE OF THE SENSORS

The average life of the sensors:

Catalytic: in a clean environment the life can be of 3/4 years. In presence of

pollution, the average life is reduced and as well the sensitivity.

Electrochemical cell: in a clean environment, the life can be of 2/3 years. In

presence of pollution, the average life of the sensor rapidly decreases.

Semiconductor: in a clean environment the life can be of 3/4 years. In presence of

pollution, the average life rapidly decreases and the values reading is altered.

Infrared: in a clean environment the life can be of 5 years.

MAINTENANCE

The Gas detectors maintenance is mandatory and it ensures the proper functioning

of the sensor.

The maintenance has to be planned according to the installation site and to the

deterioration experienced by the sensors in the various environments, at least every

6 months.

All operations must be executed in compliance with the relevant regulations in force.

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 9/14

G7-RL 3 Relais interface

Description

The 3 relays interface provide a free of voltage relay for each single event: alarm, prealarm

and detector fault.

It is possible to set each single relay contact as NO or NC, trough the jumpers on board.

Power supply can be set to 12Vdc or 24Vdc opening or closing the dedicate jumper.

J1 Terminal board

1 Alarm output

2 Alarm output

3 Prealarm output

4 Prealarm output

5 Failure output

6 Failure output

Settings

STR3 Opened 24Vdc -Closed 12Vdc

STR4 Prealarm position 1-2 NC, 2-3 NO

STR5 Alarm position 1-2 NC, 2-3 NO

STR6 Failure position 1-2 NC, 2-3 NO

Technical Features

Power Supply 12/24 Vdc

Relay contacts current max 1A @ 30Vdc

Relay contacts current max 0,5A @ 12Vdc

Warning

Using relays interface, it’s mandatory to have a power supply of at least 10 Vdc

when working at 12Vdc, or at least 22 Vdc when working at 24 Vdc.

Layout

STR3

J1

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 10/14

G7-AS Conventional Interface

Description

The interface is developed to keep simple.

The connection to input modules, or to conventional panels, requires this interface has to

be ordered with the specific resistors, for the specific panel/modules.

The resistors have to be pre-configured in manufacturer laboratories.

The interface allows a 2 wires connection without any balancing resistor.

Electronic Board type G7-AS

J1 Terminal board

1 Zone positive

2 Zone negative

Layout

Note

Before connecting the interface to the module or to the panel, verify that the balancing

resistors are correct for the module/panel it self.

J1

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 11/14

G7-42 4-20mA Interface

Description

The G7-42 interface manages a 4-20mA output in the following way:

1. Active output with positive signal (Default)

2. Active output with negative signal

3. Passive output with positive signal

4. Passive output with negative signal

Electronic Board type G7-42

Settings

Type

Board G7-42

Base Board 1

Str1

Str3

Str4

Str5

Str5

1

Close 2-3

Open

Close

Close 2-3

Open

2

Close 1-2

Close

Open

Close 1-2

Open

3

Open

Open

Close

Close 2-3

Close

4

Open

Close

Open

Close 1-2

Close

J1 Terminal board

Terminal

Type 1

Type 2

Type 3

Type 4

1

Positive

Negative

Positive

Negative

2

Negative

Positive

Negative

Positive

Layout

Note

Jumpers can be only moved with the board is switched off (without power supply).

Verify very well the right output type required, before power on.

A wrong setting may damage the interface.

STR3

STR4

J1

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 12/14

G7-LE ENEA protocol Interface

Description

The interface has been developed in order to be connected directly to control panels with

ENEA (INIM) protocol Loop lines. The communication support the different sensor types

(Methane, Hydrogen, Propane, etc) and the real time analog value with three types of

measurement units: L.E.L, P.P.M, %

Sensor addressing

As other ENEA devices, G7-LE interface has a serial-number address on board.

To assign to the control panel, refer to ENEA manuals and documentation.

Electronic Board type G7-LE

J1 Terminal board

1 - Loop IN

2 + Loop IN

3 - Loop OUT

4 + Loop OUT

Layout

J1

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 13/14

NOTE

IMPORTANT NOTE. Use a properly shielded

cables size,conforming installation features, and

connected the shield.________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

_________________________________

Gas detector Moon-2 series - Installation manual.

Micromac reserves the right to make changes to the product and the

manuals without any notice.

File: Moon-2 UM1_IT.pdf

Rev. 04- 16 10 17

Page 14/14

INIM Electronics S.r.l.

Via Fosso Antico

Loc. Centobuchi

63033 Monteprandone (AP)

www.inim.biz

This manual suits for next models

1

Table of contents

Other INIM Electronics Security Sensor manuals

INIM Electronics

INIM Electronics OTT100H Assembly instructions

INIM Electronics

INIM Electronics Air2-OTT100W Assembly instructions

INIM Electronics

INIM Electronics ED100 Technical specifications

INIM Electronics

INIM Electronics Air2 Series Assembly instructions

INIM Electronics

INIM Electronics EB0020 User manual

INIM Electronics

INIM Electronics ODI100H Assembly instructions

INIM Electronics

INIM Electronics ID100 User manual

INIM Electronics

INIM Electronics Air2 Series Assembly instructions