English

- 22 -

ROTARY HEAD (optional accessory)

Thehighpressurewashercanbettedwithaheadwithrotary

nozzle to clean the most stubborn dirt.

Danger:

Aim the jet from a certain distance to avoid damage caused by

the high pressure.

Do not aim the jet at people, animals or electrical sockets.

STOPPING THE CLEANER

1)Afterusingwithdetergent,ushouttheintakecircuit;place

thedetergentsuctionhose(g.8)inatankofcleanwaterand

let the pump run for 1 minute with the dosing tap turned fully

on and the lance in detergent delivery condition.

2) Stop the cleaner by turning the selector switch to pos. "0"

(g.6A).

3) Discharge the pressure from the H.P. hose by pressing the

triggeronthegun(g.5A).

4) Disconnect the water cleaner from the mains electricity

supply via the omnipolar switch or by unplugging the plug from

the socket.

5)Turnothewatersupplytap(g.4A).

Warning

-Ifthewatercleanerisleft,eventemporarily,turnitobyusing

the omnipolar switch or by unplugging the plug from the socket.

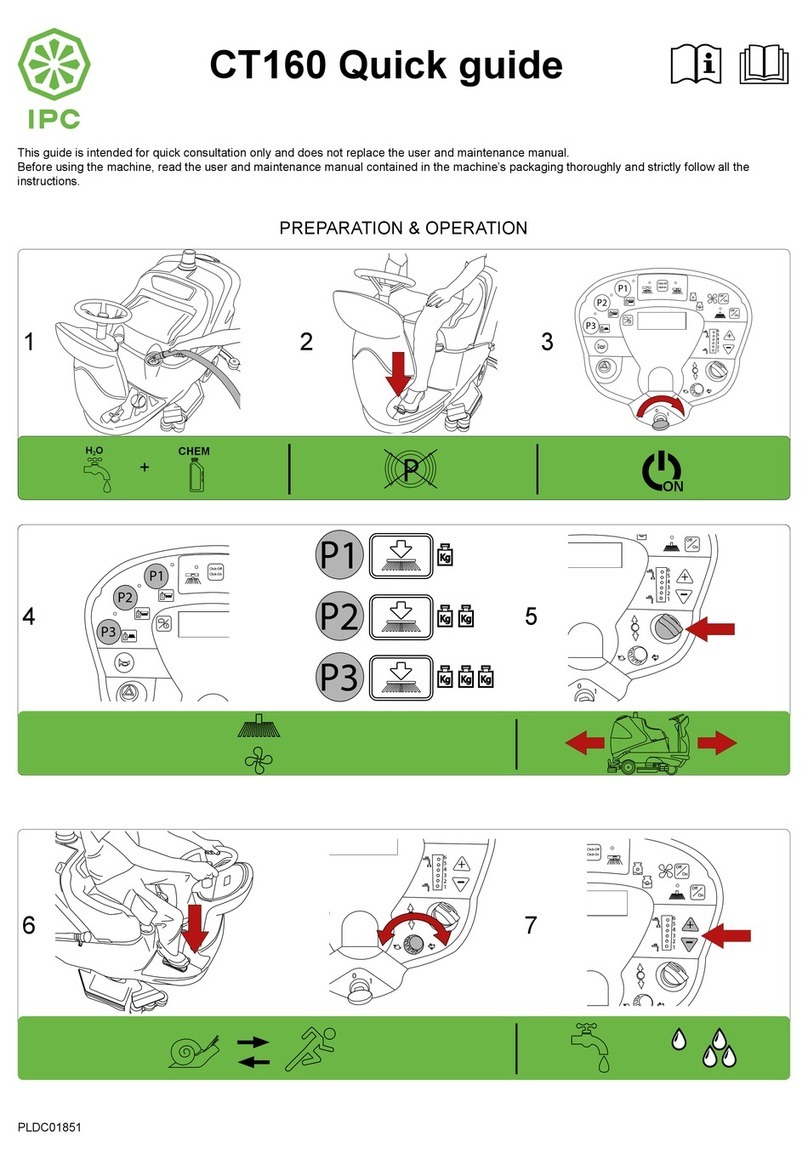

STARTING THE CLEANER

1)Turnonthewatersupplytap(g.4A).

2) Connect the water cleaner to the mains electricity supply via

the omnipolar switch or by plugging the plug into the socket.

3) Start the cleaner by turning the selector switch to pos. 1

(g.6A).

Warning

The high pressure water jet generates a reaction force in the

lance.Keeparmgriponthelancehandle.

4) Press the trigger on the gun and begin washing.

Warning

In water cleaners with the “Total Stop” system, the motor starts

and stops when the lever on the lance handle is actioned or

released.

Danger

Do not block the handle lever in the delivery position.

Warning

If malfunctions are found at startup, refer to the chapter "Trouble

Shooting".

SIGNALS AND FAULTS DISPLAYED.

Indicator light B): Power is on when the indicator light is on

steady(switch“A”inpos.I);whentheindicatorlightisashing,

the high pressure washer is in “TSI” status.

Indicator light C): Fault indicator:

-2ashes,minorleakalarm:

Minor leaks detected or water nozzle clogged: the high pressure

washer shuts down.

-3ashes,nowateralarm:

After 3 minutes of operation with no water detected, the high

pressure washer shuts down.

-4ashes,motorthermalprotectoractivated:

The high pressure washer shuts down.

-5ashes,anti-oodsystemactivated:

After 1 hour of non-stop operation, the high pressure washer

shuts down.

Indicator light D): 200h programmed maintenance interval

expired. The light will go o following maintenance by the

authorised service centre.

N.B. To reset the fault si-

gnals, turn main switch “A”

to pos. “0” and then back

to pos. “I”.

For further assistance, con-

tact the technical service

centre.

IMPORTANT!

To eliminate any impurities

or air bubbles from the wa-

ter circuit we advise starting

the cleaner for the rst time

without the lance and letting

the water run out for a few

seconds.

Impurities could block the

nozzle and cause malfun-

ction (Fig. 7).

USING THE ACCESSORIES.

The high pressure washer

hasanozzlewithaatjetfor

cleaning large surfaces.

Warning

Aim the jet from a certain

distance to avoid damage

caused by the high pressure.

USING

THE CLEANER

CONTROL PANEL

A-On/oswitch

Indicator lights (if featured).

B - Power indicator light.

C - Fault indicator light.

D - Programmed maintenance

indicator light.

!

!

!

!

!

!

!

FIG. 7

FIG. 6

FIG. 8

A

B C D