CHECKOUT, CALIBRATION AND MAINTENANCE

GENERAL1

SHAFT IMBALANCE, WHEELADAPTER TO SHAFT REMOUNT TEST1

BALANCER DIAGNOSTICS (TROUBLESHOOTING)1

TROUBLESHOOT USING CORRECT DIAGNOSTICS PROCEDURES 1-2

TOOLS REQUIRED WHEN SERVICING THE Y2K BALANCERS1-2

FUNCTIONS OF SNAPON / JBC VPI BALANCERS1-3

SERVICE CODES1-3

F/P CODE DESCRIPTIONS OF THE BALANCER1-4

F/P 1 TOGGLE FINE WEIGHT MODE 1-4

F/P 2 RIM WIDTH INCH / MILLIMETER 1-4

F/P 3 GRAM / OUNCE1-4

F/P 4 CALIBRATION WITH ADAPTER OR DISABLE ADAPTER COMPENSATION 1-4

F/P 7 TOGGLE MILLIMETER AND INCH FOR DIAMETER 1-4

F/P 12 READ COUNTERS 1-4

F/P 14 USER CALIBRATION PROCEDURE 1-5

F/P 18 ALU-S MODE1-5

F/P 19ALU-S ONE PLANE BALANCING MODE 1-5

F/P 21 KERNEL SOFTWARE1-5

F/P 28 KERNEL ERROR MESSAGES 1-5

1-6

F/P 43 RESETTING THE COUNTERS 1-6

F/P 44 READ OR RESET PRODUCTIVITY OF USER 1-6

F/P 50 READ OUTPUT VOLTAGE OF THE DISTANCE POTENTIOMETER OF SAPE 1-6

F/P 51 READ OUTPUT VOLTAGE OF THE DIAMETER POTENTIOMETER OF SAPE 1-6

F 52 READ OUTPUT VOLTAGE OF THE WIDTH POTENTIOMETER 1-7

F/P 53 DISPLAY TEST1-7

F/P 55 CHECKAC AND DC VOLTAGES 1-7

F/P 56 CHECK PEDALAND HOOD SWITCHES ON POWER CLAMP 1-7

F/P 59 DISPLAYS THE UNBALANCE OF THE BARE SHAFT 1-7

F/P 60 READ SHAFT RPM 1-7

F/P 63 CONTINUOUS BALANCING 1-7

F/P 64 DISPLAYS THE TRANSDUCER OUTPUT 1-7

F79 CALIBRATION OF WIDTH SAPE 1-8

F/P 80 SAPE GAUGE CALIBRATION 1-9

F/P 83 FACTORY CALIBRATION PROCEDURE 1-11

F/P 84 EMPTY SHAFT CALIBRATION PROCEDURE 1-13

F/P 88 TDC CALIBRATION 1-13

F/P 90 MATCH BALANCE1-14

F/P 91 OPTIMIZATION 1-14

F/P 92 SPLIT WEIGHT 1-14

F/P 94 SPOKE MODE 1-14

F/P 95 CLEAN & RESET EEPROM 1 & 2 1-14

F/P 97 STICKYAT TOP STOPAT TOP 1-14

SERVICING THE BALANCER1-15

CONTROL PANEL REMOVAL & REPLACEMENT1-15

MAIN PROCESSOR REPLACEMENT1-16

TOACCESS THE INSIDE OF THE MACHINE1-17

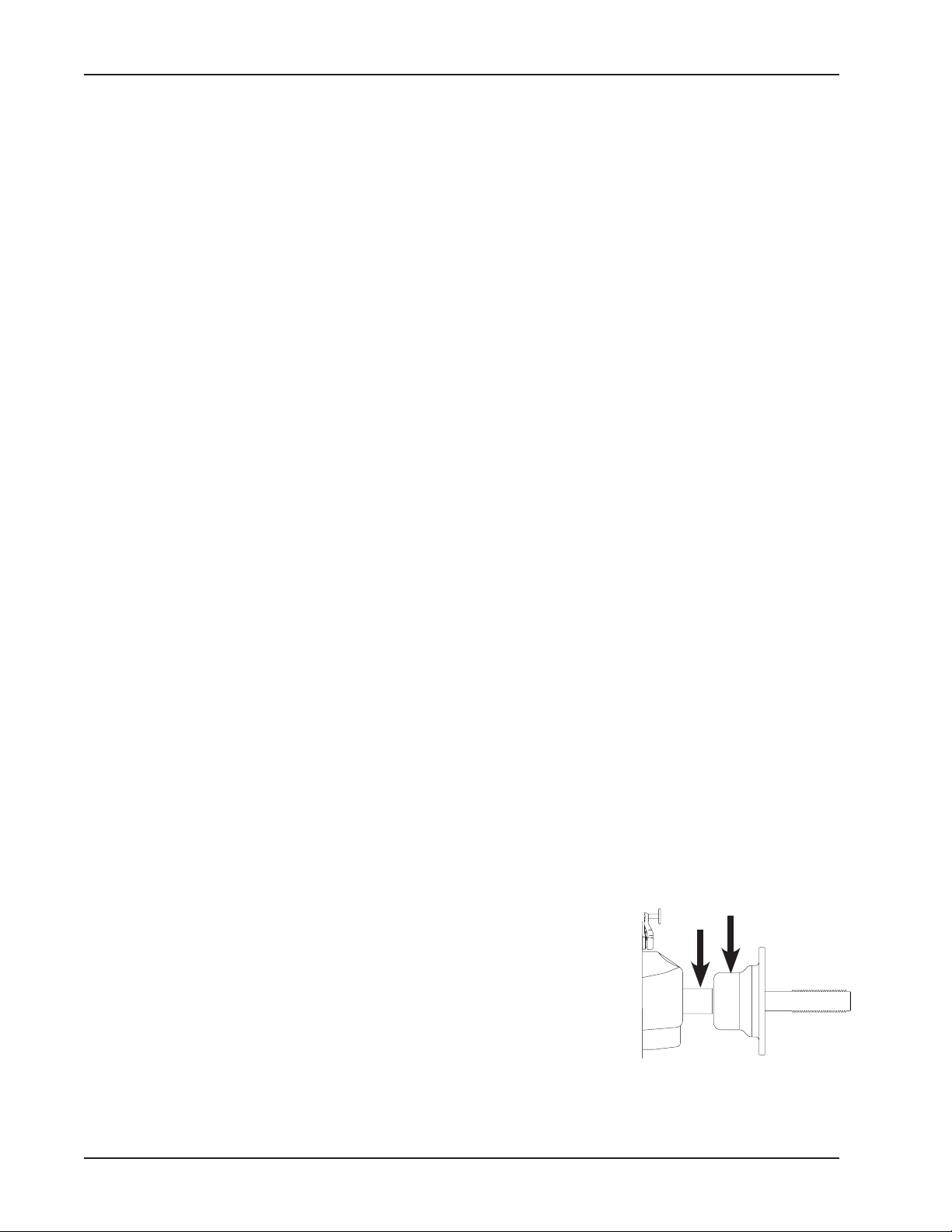

TRANSDUCER REMOVAL 1-18

INSTALLATION OF TRANSDUCER1-18