Contents

1 Typographical conventions ...................................................... 8

1.1 Warning signs ..............................................................................................8

1.2 Attention-drawing signs ...............................................................................8

2 General ....................................................................................... 9

2.1 Foreword ......................................................................................................9

2.2 Structure of the JUMO CTI-750..................................................................10

3 Inductive conductivity measurement .................................... 11

3.1 Field of application .....................................................................................11

3.2 Function .....................................................................................................12

4 Identifying the device ............................................................. 13

4.1 Type nameplate .........................................................................................13

4.2 Type declaration ........................................................................................14

4.3 JUMO CTI-750 as "Head transmitter" ........................................................14

4.4 JUMO CTI-750 as "Transmitter with separate sensor" .............................15

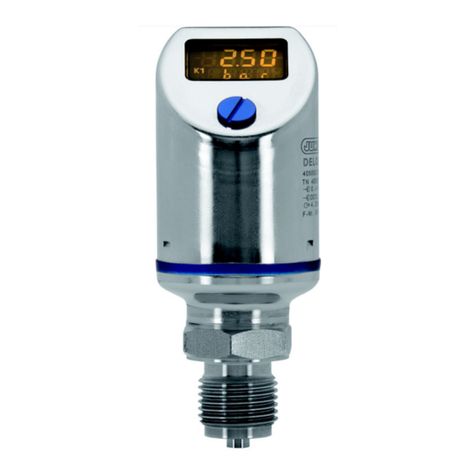

5 Device description .................................................................. 17

5.1 Technical data, transmitter ......................................................................17

6 Assembly .................................................................................. 21

6.1 General ...................................................................................................... 21

6.2 Dimensions / Process connections, head transmitter ...............................22

6.3 JUMO CTI-750 with separate sensor ........................................................24

6.4 Assembly examples ...................................................................................28

7 Installation ............................................................................... 30

7.1 General ......................................................................................................31

8 Setup program ........................................................................ 34

8.1 Function .....................................................................................................34

9 Commissioning ....................................................................... 35

9.1 Head transmitter or transmitter with separate sensor ...............................35

9.2 Replacement sensor ..................................................................................35