V1.00/EN/00477047

Page 2/12Data Sheet 202565

JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Internet: www.jumousa.com

Operation

For easy programming and operation, all

parameters are arranged in clearly structured

levels and shown in plain text. Operation is

protected by a code word. This facilitates

individual adaptation of the operation, since

parameters can be generally enabled or

specifically assigned to the protected area.

As an alternative to configuration from the

keys, the instrument can also be configured

through the convenient setup program for PC

(option).

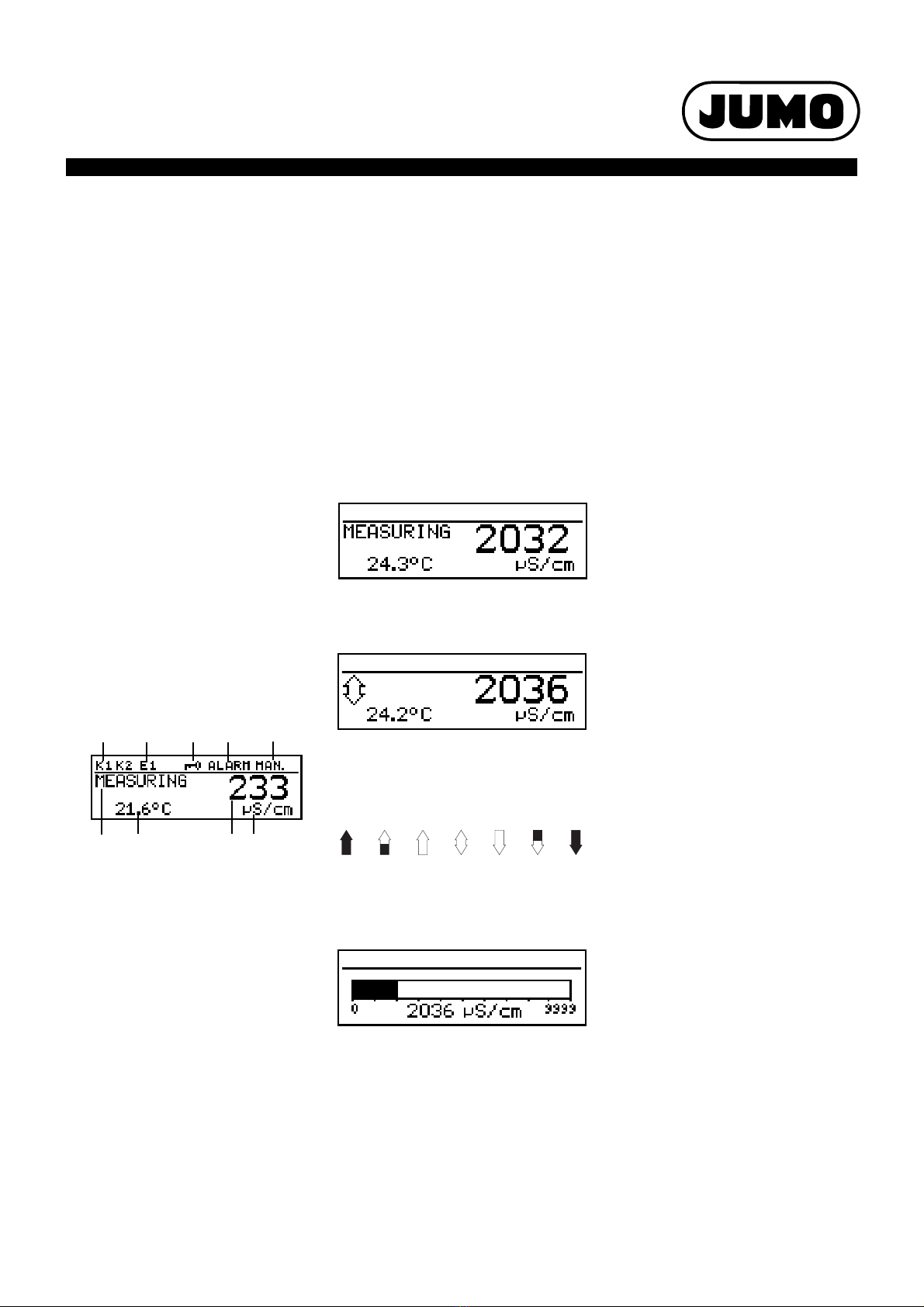

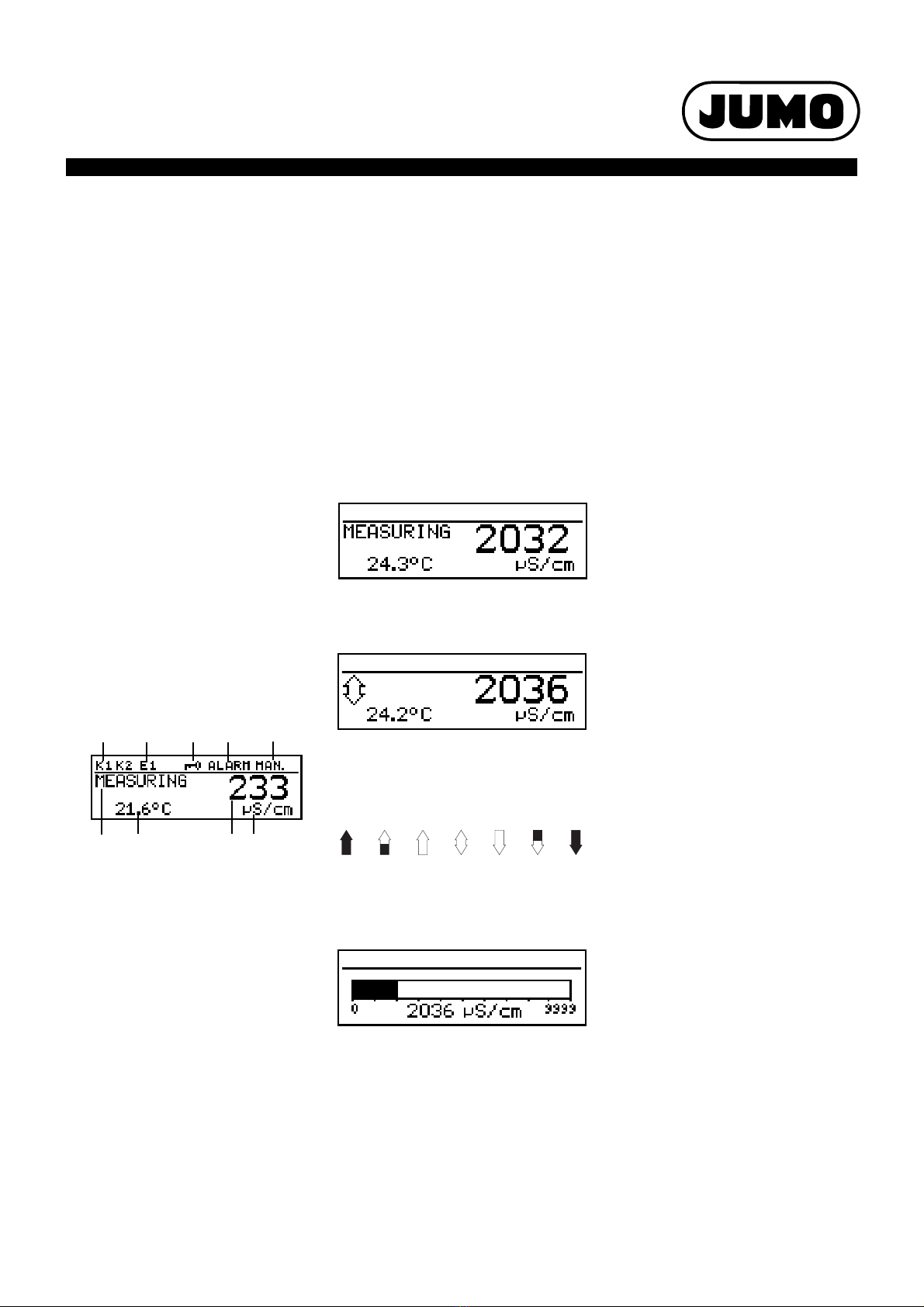

Display modes

Three display modes are available:

Large numbers

In this display mode, the measurements are

shown in digits, as usual.

Trend display

The numerical value is supplemented by a

symbol which indicates the change direction

and change speed of the measurement.

This can, for instance, be very useful during

controller optimization.

from left to right:

fast, medium and slow rise, stable,

slow, medium and fast fall.

Bar graph

This display mode allows the user to see at a

glance in which region the measurement is at

present.

The bar graph can be freely scaled.

Function modes

Electrolytic conductivity

Display/control, unit µS/cm or mS/cm.

Resistivity (high-purity water)

Display/control, unit kΩx cm or MΩx cm.

Functional description

The instrument is designed for use on site. A

rugged housing protects the electronics and

the electrical connections from corrosive

environmental conditions (IP67). As an

alternative, the instrument can also be

installed in a control panel, and is then

protected to IP65 on the front. The electrical

connection is made by easy-to-fit pluggable

screw terminals.

Transmitter

Two-electrode cells (standard) as well as four-

electrode cells can be used for measurement.

Two-electrode cells can be connected, in the

usual increments for cell constants (K=0.01;

0.1; 1.0; 3.0 and 10.0). Thanks to the widely

adjustable relative cell constant, it is also

possible to connect sensors with different cell

constants (e.g. K=0.2).

In the case of the 4-electrode cells, the values

K=0.5 and 1.0 have been predefined for the

cell constant. Here too, the instrument can be

matched to sensors with different cell

constants (e.g. K=0.4).

The instrument can perform automatic

temperature compensation, by acquiring the

temperature of the sample solution.

Displays and controls

(1) Switching output 1 or 2 is active

(2) Binary input 1 is actuated

(3) Keypad is inhibited

(4) Alarm has been activated

(5) Instrument is in manual mode

(6) Instrument status

(7) Temperature of medium

(8) Principal measurement

(9) Unit of principal measurement

The user can define what is to be shown in

positions (7) and (8) of the display:

•nodisplay

• compensated or uncompensated

measurement

•temperature

• output level 1 or 2

•setpoint1or2

(1) (2) (4) (5)

(6) (7) (8) (9)

(3)

TDS

Display/control with ppm for the unit.

In this mode, the specific TDS factor can be

entered in addition.

Customer-specific table

In this mode, the input value (conductivity or

resistivity) can be displayed in accordance

with a table (up to 20 value pairs). Thanks to

this function, it is possible to implement

simple concentration measurements, for

example. The values in the table can only be

entered through the optional setup program.

Calibration

Cell constant

Because of manufacturing tolerances, the cell

constant of a conductivity cell may deviate

slightly from its nominal value. In addition, the

cell constant may change during operation

(due to deposits or wear, for example). This

results in a change of the output signal from

the cell. The instrument provides the user with

the possibility of compensating any deviation

from the nominal value of the cell constant by

manual entry or automatic calibration of the

relative cell constant. A manual entry is used,

for instance, for calibration during high-purity

water measurement.

Temperature coefficient

The conductivity of almost all solutions

depends on the temperature. To ensure

correct measurement, it is therefore

necessary to know both the temperature and

the temperature coefficient [%/°C] of the

sample solution. The temperature can either

be measured automatically, with a Pt100 or

Pt1000 temperature probe, or it has to be set

manually by the user.

The temperature coefficient can be

automatically determined by the instrument,

or it can be entered manually.

Calibration logbook

The five most recent successful calibrations

can be called up in the calibration logbook.

This makes it possible to evaluate the ageing

of the sensor that is connected.

Calibration timer

The calibration timer indicates (if required)

when the next routine calibration is due. The

calibration timer is activated by entering a

number of days, after which recalibration has

to be carried out (plant or operator

requirement).

MIN / MAX value memory

This memory acquires the minimum or

maximum input variables that have occurred.

This information serves, for example, to

decide whether the sensor that is connected

is suited to the values that are actually

present.