8

3 Inductive conductivity measurement

3.1 Area of application

General The inductive measurement method permits largely maintenance-free

acquisition of the specific conductivity, even in difficult media conditions.

Unlike the conductive measurement method, problems such as electrode

decomposition and polarization do not occur.

Brief

description The instrument is used for the measurement/control of conductivity or

concentration in liquid media. It is particularly recommended for use in media

where severe deposits of dirt, oil, grease or gypsum/lime precipitates are to be

expected. The integrated temperature measurement enables fast and

accurate temperature compensation, which is of particular importance when

measuring conductivity. Additional functions, such as the combined

changeover of measurement range and temperature coefficient, enable

optimum application in CIP processes.

Two built-in switching outputs can be freely programmed to monitor limits for

conductivity/concentration and/or temperature. It is also possible to assign

alarm and control functions (dilution).

The instrument is operated either from the membrane keypad and plain-text

graphics display (operator language can be changed over) or through the user-

friendly PC setup program. Simply rotating the housing cover makes it

possible to read the display, regardless of whether the installation is in

horizontally or vertically arranged pipes. By using the setup program, the

instrument configuration data for plant documentation can be saved and

printed out. To prevent any tampering, the instrument can also be supplied

without keypad or display. In this case, the setup program is needed for

programming.

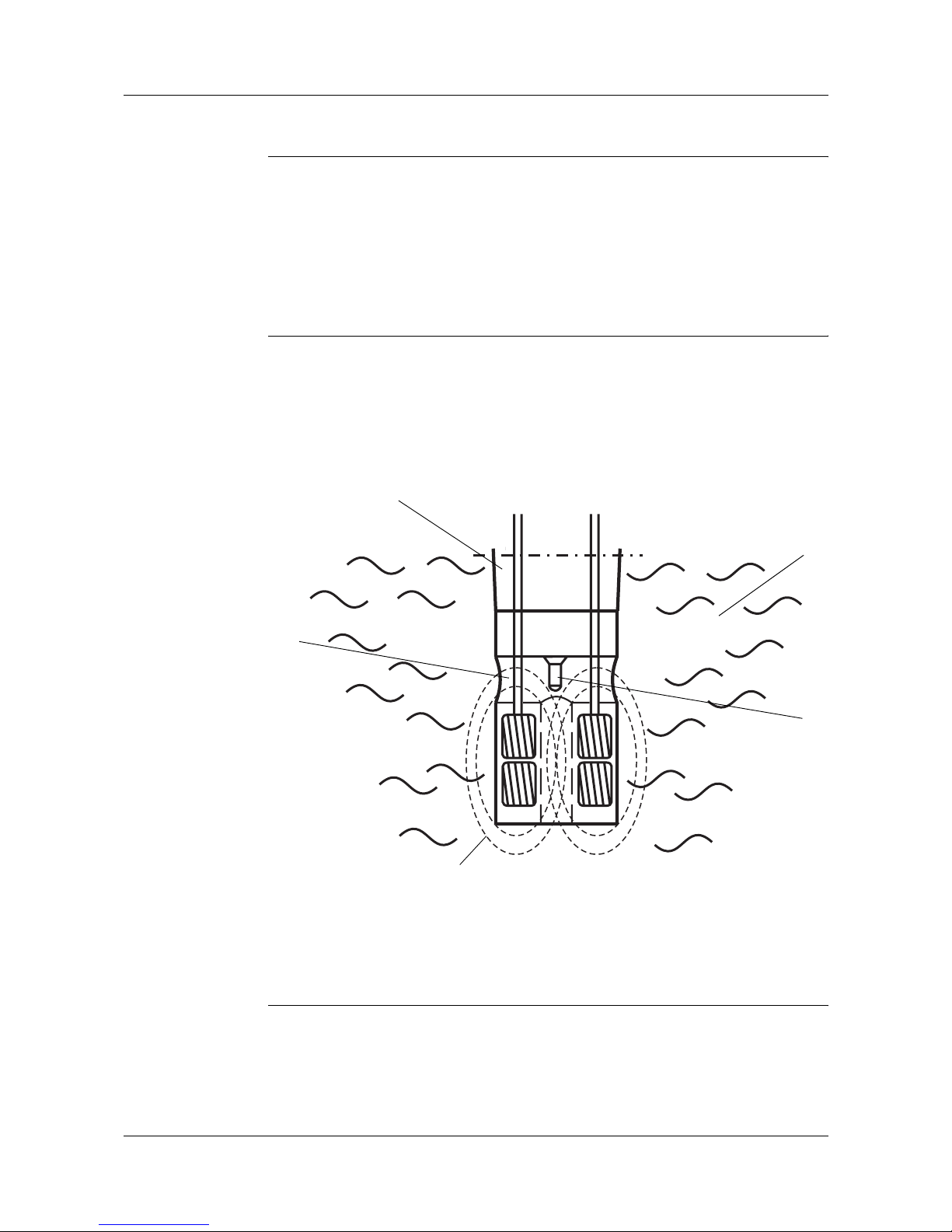

The JUMO CTI-750 is available either as a combined unit (transmitter and

measuring cell together in one unit) or as a split version (transmitter and cell

connected by cable). The split version is particularly suitable for plant

subjected to strong vibration and/or significant heat radiation at the point of

measurement, or for installation on sites that are difficult to access.

Typical areas of

application - CIP cleaning (CIP = Clean In Place/Process)

- concentration monitoring or dosing of chemicals

- food/beverage and pharmaceutical industries

- product monitoring (phase separation of product / product mix / water)

in the beverage industry, breweries, dairies

- control (e.g. phase separation of detergent / rinsing water in

cleaning processes, e.g. bottle cleaning plant, or for container

cleaning)