JUMO GmbH & Co. KG

Delivery address: Mackenrodtstraße 14

36039 Fulda, Germany

Postal address:

36035 Fulda, Germany

Phone: +49 661 6003-0

Fax: +49 661 6003-607

Internet: www.jumo.net

JUMO Instrument Co. Ltd.

JUMO House

Temple Bank, Riverway

Harlow, Essex CM20 2DY, UK

Phone: +44 1279 635533

Fax: +44 1279 635262

Internet: www.jumo.co.uk

JUMO Process Control, Inc.

6733 Myers Road

East Syracuse, NY 13057, USA

Phone: 315-437-5866

1-800-554-5866

Fax: 315-437-5860

Internet: www.jumousa.com

V1.00/EN/00520247

Page 2/12Data Sheet 202566

(3)Keyboard inhibited

(4)Alarm has been activated

(5)Instrument is in manual mode

(6)Instrument status

(7)Medium temperature

(8)Main measurement

(9)Unit of main measurement

The user can specify what is to appear in

positions (7) and (8) of the display:

-Nodisplay

- Corrected or uncorrected measurement

-Temperature

- Output level 1 or 2

-Setpoint1or2

Operation

To make programming and operation easy, all

parameters are clearly assigned to levels and

displayed in plain text. Operation is protected

by a code word. Operation can be adapted on

an individual basis because parameters can

be generally enabled or assigned to the

protected area.

A setup program for the PC is available as a

more convenient configuration option, rather

than using the instrument keyboard.

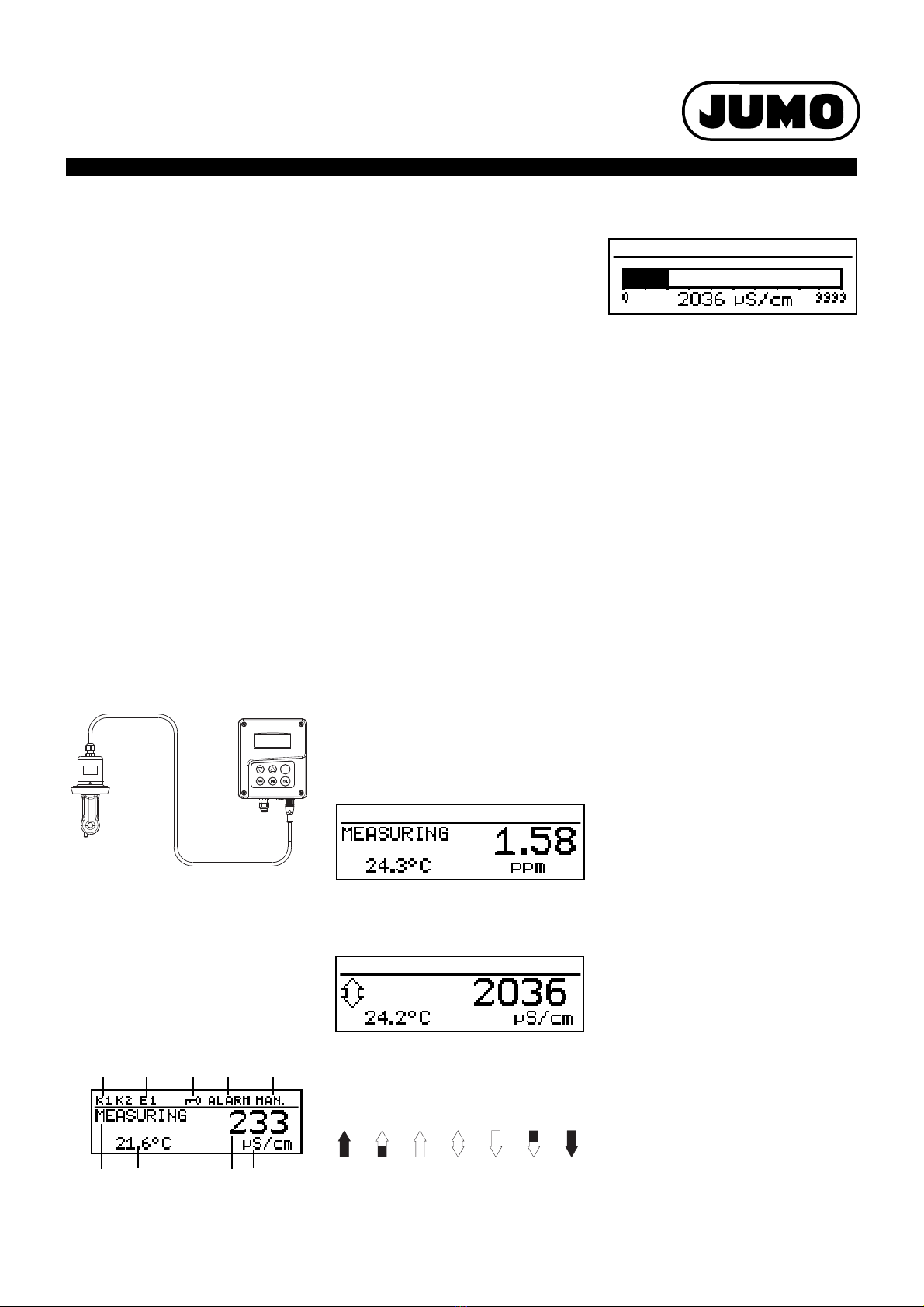

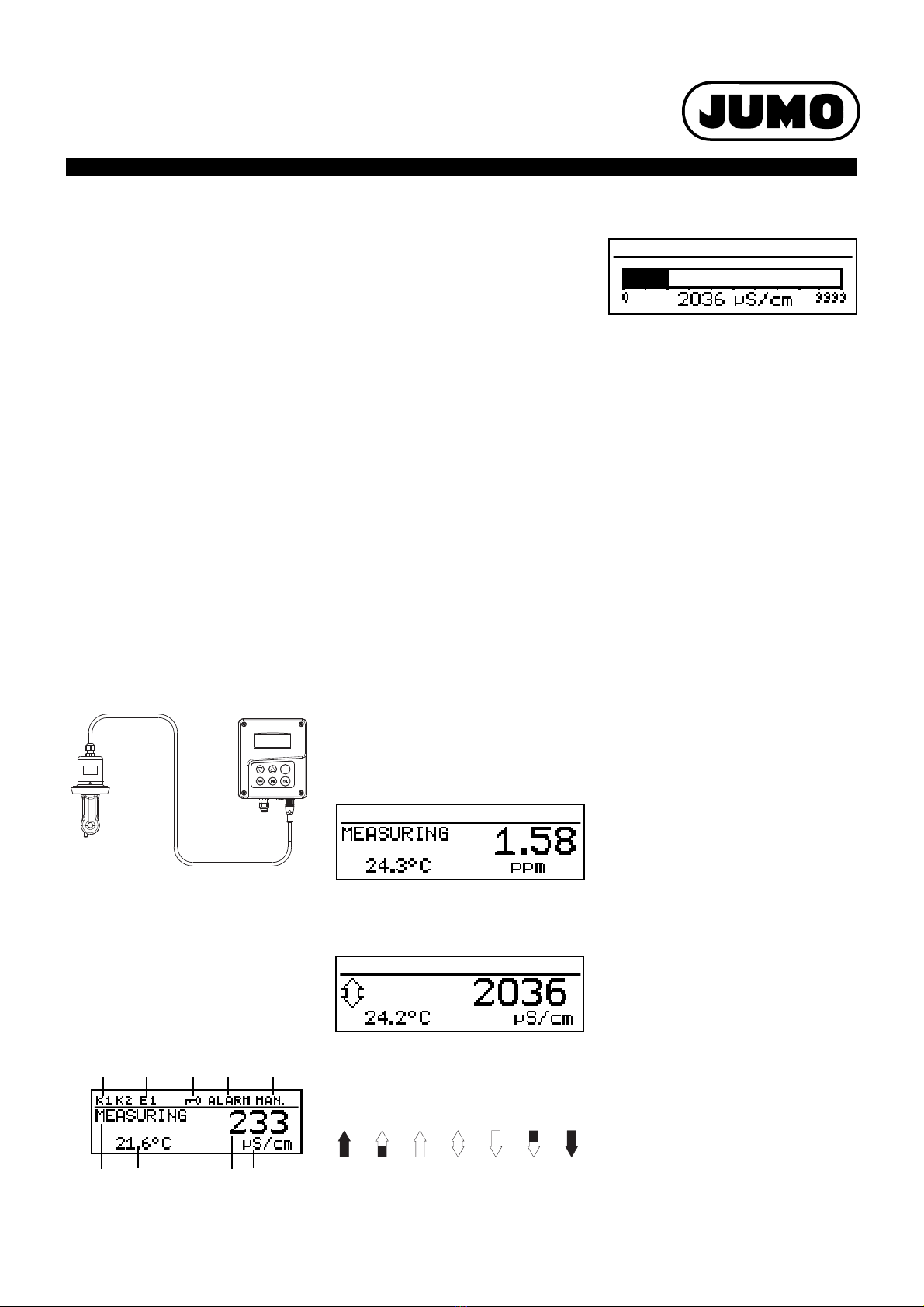

Display modes

Three display modes are available:

Large numbers

Here the measurements are displayed in

numbers, as usual.

Trend display

Here the numerical value is supplemented by

a symbol to indicate the direction and speed

of change for the measurement.

This can be very useful when the controller is

being optimized, for example.

from left to right:

fast, medium and slow rise,

steady,

slow, medium and fast fall.

Functional description

The instrument is designed for on-site use. A

robust housing protects the electronics and

electrical connections against aggressive

environmental conditions (IP67). As an

alternative, the instrument can also be

installed in a panel; the front then has IP65

enclosure protection. Easily installed screw

connectors are used for electrical connection.

A ventilation screw with a PTFE membrane

prevents condensation buildup.

Transmitter

The transmitter receives the measurement

signal from the inductive measuring cells of

the JUMO tecLINE Ci series, see data sheet

202941.

With the inductive measurement method,

acquisition of specific conductivity is largely

maintenance-free, even in the most difficult of

medium conditions. Unlike the conductive

measurement method, there are practically no

problems such as electrode breakdown and

polarization.

By acquiring the temperature of the sample

medium, the instrument can automatically

perform temperature compensation.

Components of the measurement

chain

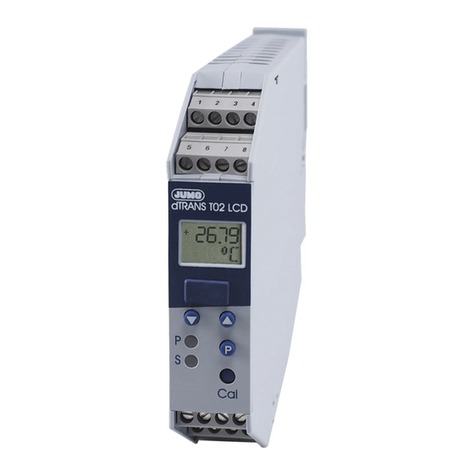

Displays and controls

(1)Switching output 1 or 2 is active

(2)Binary input 1 is triggered

(1) JUMO tecLine Ci, inductive

conductivity and temperature sensor

(2) Cable

(JUMO tecLine Ci component)

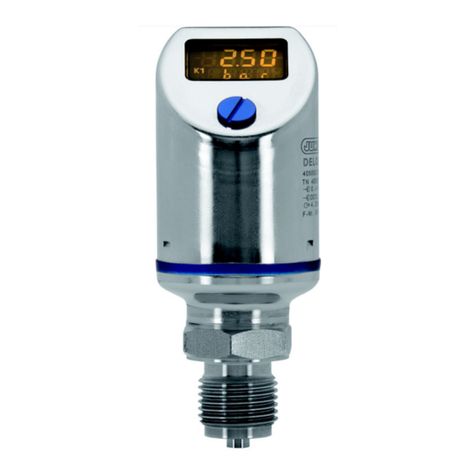

(3) JUMO AQUIS 500 Ci, transmitter/

controller for conductivity,

concentration and temperature

(1) (2) (4) (5)

(6) (7) (8) (9)

(3)

Bar graph

In this display mode, it only takes a glance to

ascertain the range for the current

measurement.

Any scale can be used for the bar graph.

Function modes

Electrolytic conductivity

µS/cm or mS/cm are the units used for

display and control.

Concentration measurement

Caustic soda

NaOH0 to 12 % by weight

NaOH25 to 50 % by weight

Nitric acid

HNO30to25%byweight

HNO336 to 82 % by weight

Sulphuric acid

H2SO40to28%byweight

H2SO436 to 85 % weight

H2SO492 to 99 % by weight

Hydrochloric acid

HCl 0 to 18 % by weight

HCl22 to 44 % by weight

Customized table

In this mode, the input value (specific

conductivity) can be displayed in accordance

with a table (max. 20 value pairs). This

function can be used to implement simple

concentration measurements, for example.

Table values can only be entered using the

optional setup program.

Calibration

Cell constant

Because of manufacturing constraints, the

cell constant of a conductivity measuring cell

may differ slightly from its nominal value.

Wear or the accumulation of deposits during

operation can also cause the cell constant to

change. This changes the output signal from

the measuring cell. With this instrument, the

user has the opportunity to compensate for

deviations in the nominal value of the cell

constant by manual input, or by automatic

calibration of the relevant cell constant.

Installation factor

This parameter can be used to compensate

for unfavorable sensor mounting conditions.

Temperature coefficient

The conductivity of virtually all solutions is

temperature dependent. To ensure correct

measurement therefore, both the temperature

and the temperature coefficient a [%/C] of the

measurement solution must be known. The

temperature can either be measured

automatically with a Pt 100 or Pt 1000

temperature probe, or the user must set the