Page 4

KANE456 OVERVIEW

The KANE456 Combustion Analyser measures carbon dioxide (CO2), carbon

monoxide (CO), differential temperature and differential pressure. The direct

measurement of CO2 is achieved using a Kane designed infra-red sensing system.

Below 1% CO2 the readings of CO2 are displayed to two decimal places

CO2 is set to zero in fresh air automatically after the initial countdown. The countdown

varies between 90 and 30 seconds dependent on ambient temperature.

If “RESET GAS ZERO” is indicated ensure that the unit is in fresh air before pressing

the button with an “Enter” symbol.

It calculates oxygen (O2), CO/CO2 ratio, losses, combustion efficiency (Net or

Condensing Gross).

The KANE456 Combustion Analyser can also measure CO levels in ambient air -

useful when a CO Alarm is triggered. It can also perform a Room CO Test for up to 30

minutes duration.

A structured Commissioning Test has been included for the installation of boilers.

The analyser has a protective rubber cover with a magnet for “hands–free” operation

and is supplied with a flue probe with integral temperature sensor.

A low flow detection system warns of low flow and switches the pump off. This also

helps to prevent water ingress from overfilled water traps.

Its LCD display is protected with a toughened screen.

The large display shows 6 readings at a time and all data can be printed via an

optional infrared printer. The printed data can be 'live' data or ‘stored’ data.

The memory can store up to:

60 combustion tests

20 AUX tests

20 let-by/tightness tests

20 temperature & pressure tests

20 room CO tests

20 commissioning Tests

Two lines of 20 characters can be added to the header of printouts. Printouts can be

made on the optional Kane IRP printers with ‘fast print’ capability using the IRP2

printer. Alternatively the analyser can be equipped with optional wireless

communications to either Android or Apple devices.

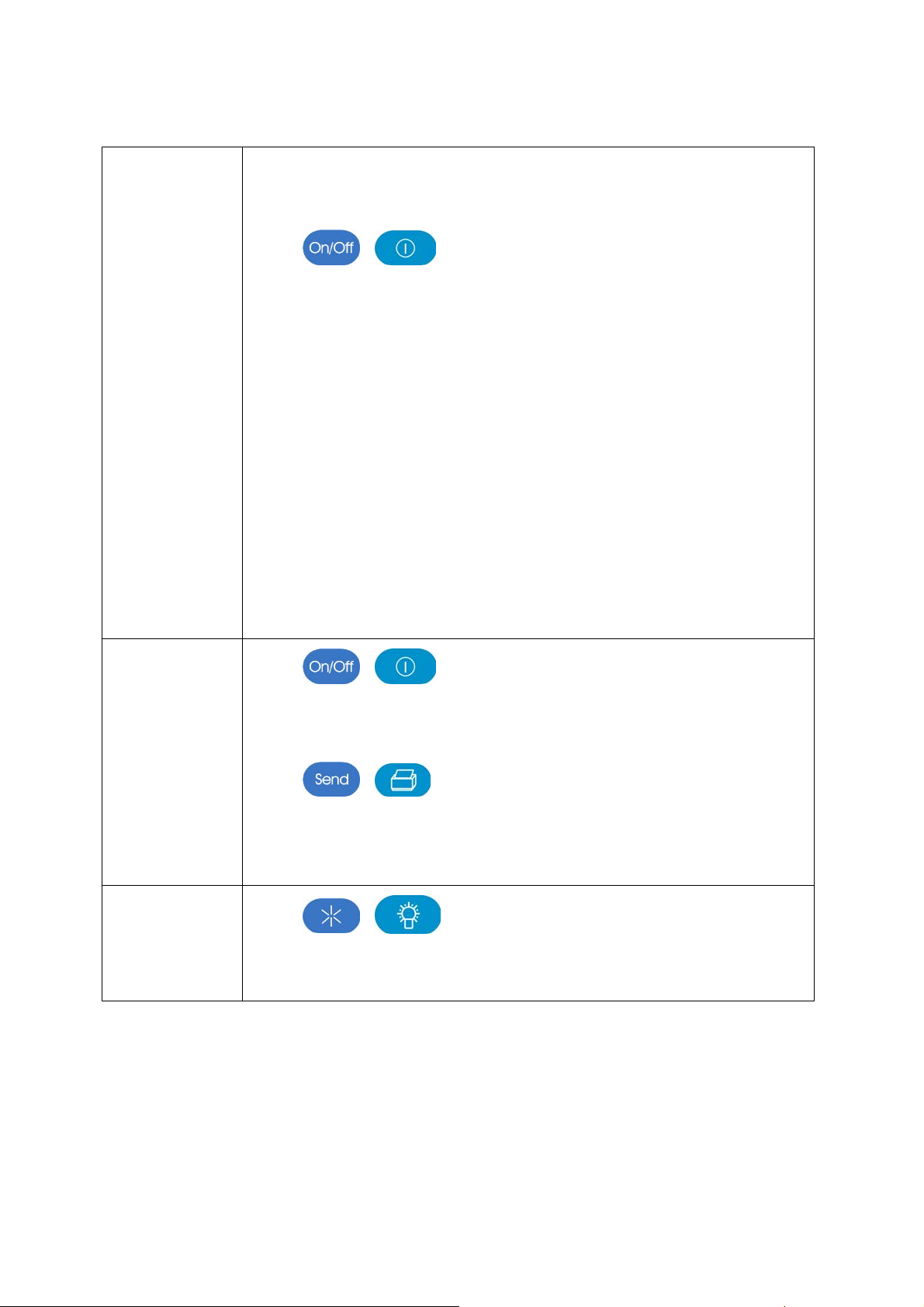

The analyser is controlled using 4 function buttons and a rotary dial.

The four buttons (from left to right) switch on and off the analyser, switch on and off

the torch light, switch on and off the pump and send data to a printer or to the memory.

The buttons with UP, DOWN and ENTER arrows also change settings such as date,

time, fuel, etc. when in MENU mode.