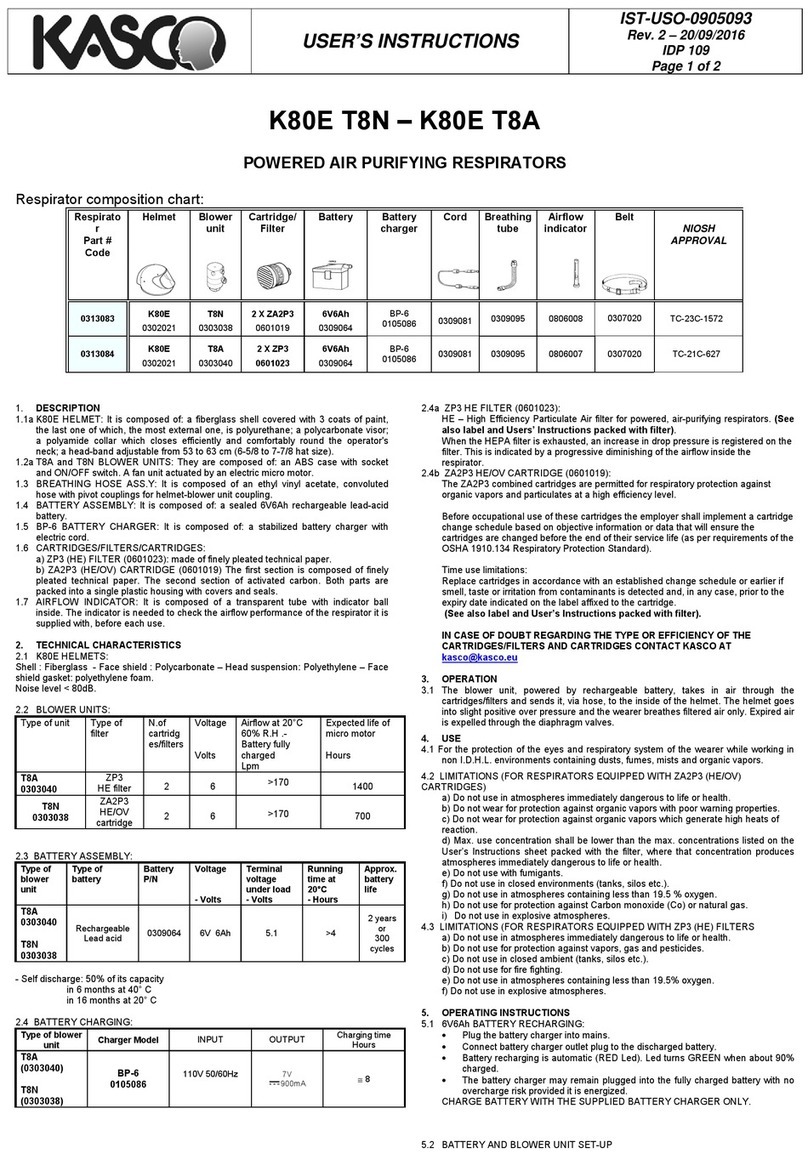

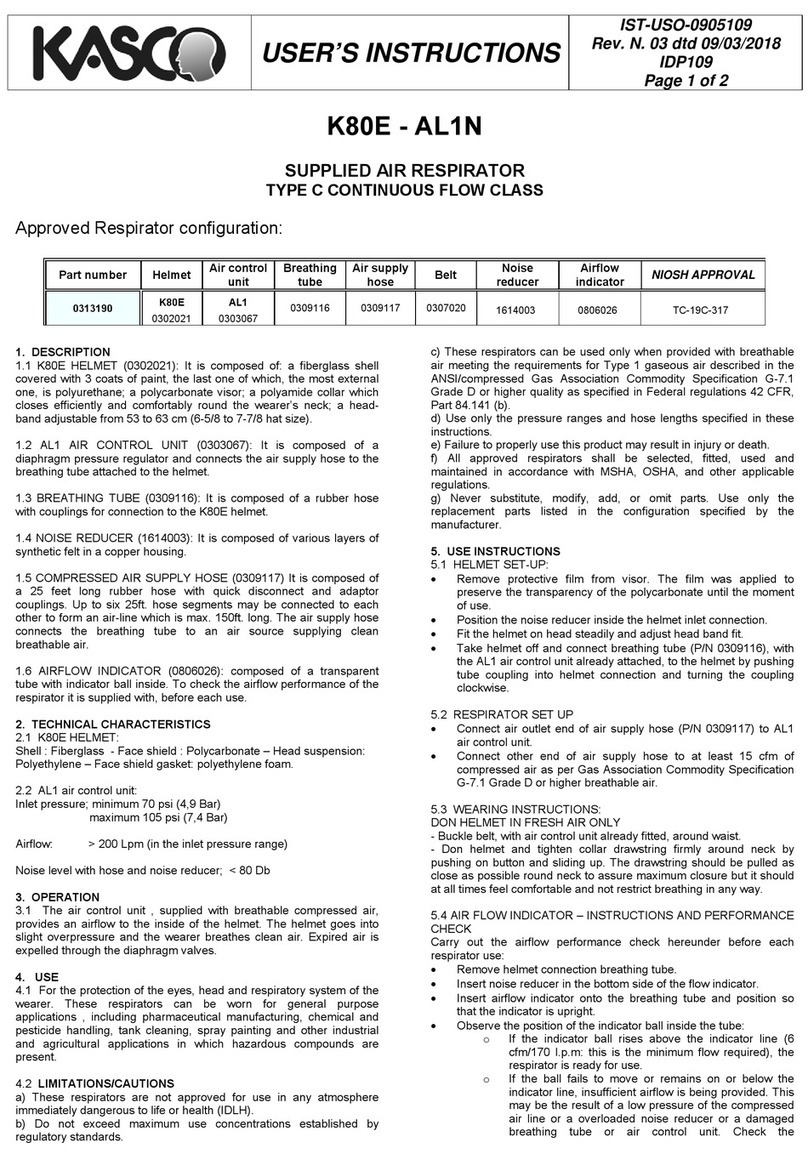

IST-USO-0905086

Rev. 4 –03/10/2016

IDP 109

Page 2 of 2

Fit the helmet on head steadily.

Adjust head band fit.

Couple breathing hose to helmet by pushing the connector into the helmet .

Open visor.

5.4 WEARING INSTRUCTIONS:

DON HELMET IN A FRESH AIR ENVIRONMENT ONLY

Position belt, with blower unit and cartridges already fitted on the left and

battery on the right (for T8N only), around waist

Don helmet and tighten collar drawstring around neck by pressing the button

and sliding it up the drawstring. The drawstring should be pulled as close as

possible around neck to assure maximum closure but it should at all times feel

comfortable and not restrict breathing in any way.

Connect breathing hose assembly to blower unit by pressing the hose connector

into the motor housing of the unit.

Close lift-up face shield.

5.5 AIR FLOW INDICATOR –INSTRUCTIONS AND PERFORMANCE CHECK

Carry out the airflow performance check hereunder before each respirator use:

Remove helmet-blower unit connection hose.

Ensure the battery is fully charged (see battery charging instructions packed with

the battery charger) and that the cartridges are fitted into the blower unit securely.

Insert airflow indicator onto the air outlet of the blower unit and position so that

the indicator is upright.

Start the unit and observe the position of the indicator ball inside the tube.

If the indicator ball rises above the indicator line (6 cfm/170 l.p.m), the

respirator is ready for use.

If the ball fails to move or remains on or below the indicator line, insufficient

airflow is being provided. This may be the result of a battery with a low

charge or an overloaded filter. Replace the filters and repeat the test.

Should the ball still remain below the indicator line, replace the battery and

repeat complete test.

Remove the airflow indicator and reconnect the breathing hose to the unit.

6 MAINTENANCE

6.1 HELMET

Clean shell with organic solvent free detergent or better still with soapy water.

Clean visor with soapy water only.

Wash collar with warm soapy water.

6.2 BLOWER UNITS

The motor does not require servicing.

Clean unit with organic solvent free detergents or better still with a cloth dipped

into a 50% water ethyl alcohol solution.

6.3 6V6Ah BATTERY

The battery does not require servicing or tipping up.

RECHARGE IMMEDIATELY AFTER EVERY USE FOR LONGER LIFE -

DISCHARGED BATTERIES NOT RECHARGED WITHIN 48 HOURS AFTER

USE CANNOT BE RECHARGED AND ARE NOT COVERED UNDER

WARRANTY.

WHILE IN STORAGE THE BATTERY MUST BE CHARGED AT LEAST

ONCE EVERY 3 MONTHS.

6.4 BATTERY CHARGERS

Store in a dry place.

Avoid hard impacts or vibrations as these could alter the setting.

6.5 CARTRIDGES

If sealed, the cartridges remain unaltered until the expiry date shown on them.

Cartridges cannot be washed, blown out or restored. When exhausted they must

be disposed of.

If two or more cartridges are connected in parallel, they are to be replaced

simultaneously.

6.6 The PAPR is to be serviced at least once a year by KASCO or KASCO authorized

service centre.

7. CAUTION

7.1- Do not use the respirator under the conditions described at paragraph 4.2.

- Do not use the respirator if it does not pass the airflow performance check (See

paragraph 5.5).

7.2- Do not use if the fan does not rotate as described at point 5.2.

- Do not immerse blower unit in water for cleaning.

- Do not use blower unit if it does not supply an airflow of at least 6cfm/170 l.p.m .

7.3 DO NOT KEEP 6V6AH BATTERY DISCHARGED - RECHARGE IMMEDIATELY

AFTER USE.

- Do not place battery near or in fire.

- Do not short the terminals.

- Do not disassemble or reassemble the battery.

- Do not place battery on or near equipment which vibrates excessively.

If dilute sulfuric acid gets into the eyes, wash immediately with plenty of water and

see a doctor.

- Do not expose battery to infrared or ultraviolet rays excessively.

7.4 - Use only the supplied battery chargers for 6V6Ah battery recharging.

- Do not keep the battery charger connected to the battery unless it is also

connected to the mains and it is energized.

- The battery charger functions at its best at average temperature (between + 15°

and + 25° C). If any problems are experienced when charging batteries at

temperatures other than the range mentioned above, contact KASCO

7.5- Do not use expired filters even if their seals are still intact.

- Do not use a filter for more than three months.

7.6 Return to fresh, clean air immediately and open visor if:

a) leakage is detected by smell, taste or eye, nose or throat irritation.

b) inhaled air becomes extremely hot.

c) any feeling of nausea, dizziness or ill being develops.

7.7 THE HELMET WILL NOT FURNISH BREATHING PROTECTION UNLESS IT IS

CONNECTED TO A FUNCTIONING BLOWER UNIT WHICH DRAWS IN AIR

THROUGH THE FILTER.

7.8 Never alter or modify this respirator in any way.

7.9 Replace the helmet after hard impacts even if it does not present any visible

damage.

7.10 This equipment is to be used only by qualified personnel trained in accordance

with a respirator program as outlined in ANSI Z 88.2-1980.

7.11 Do not use the respirator if it has not been serviced annually by a KASCO

authorized service centre.

8.REPAIRS

8.1 For respirator or part replacement contact KASCO authorized dealers and

workshop only.

8.2 Use only genuine KASCO spares.

8.3 For setting and adjustment of electric parts contact KASCO.

8.4 Any repair work is to be carried out by specialized technicians.

Should you require technical assistance for problems that could arise while using

KASCO equipment always include the following information:

a) Respirator model and blower unit with lot numbers.

b) Date of purchase.

c) Name of dealer.

d) Problem.

Also state the following:

- power used

- type of pollution and concentration of same

- place of work (indoors or outdoors)

- approx. degree of relative humidity

- amount of hours worked annually - maximum hours worked.

Also include a sketch or drawing of the type of work carried out if you feel it might be

useful.

9. WARNING

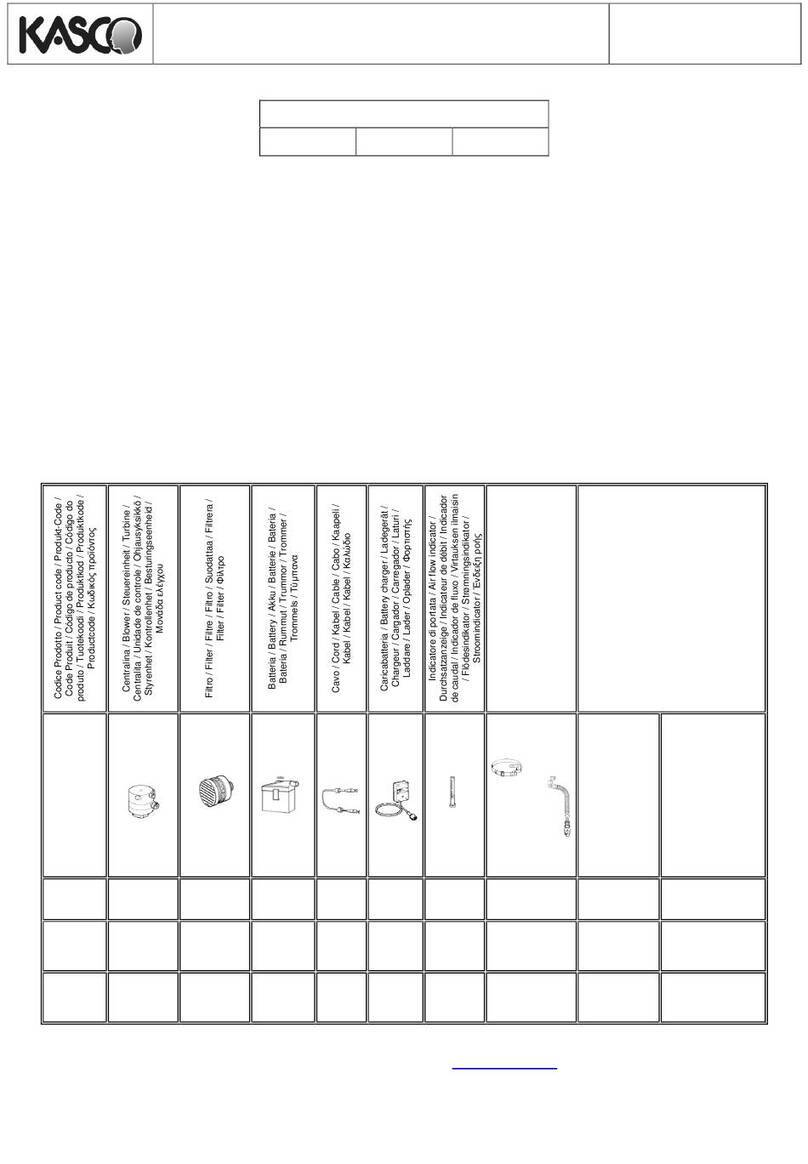

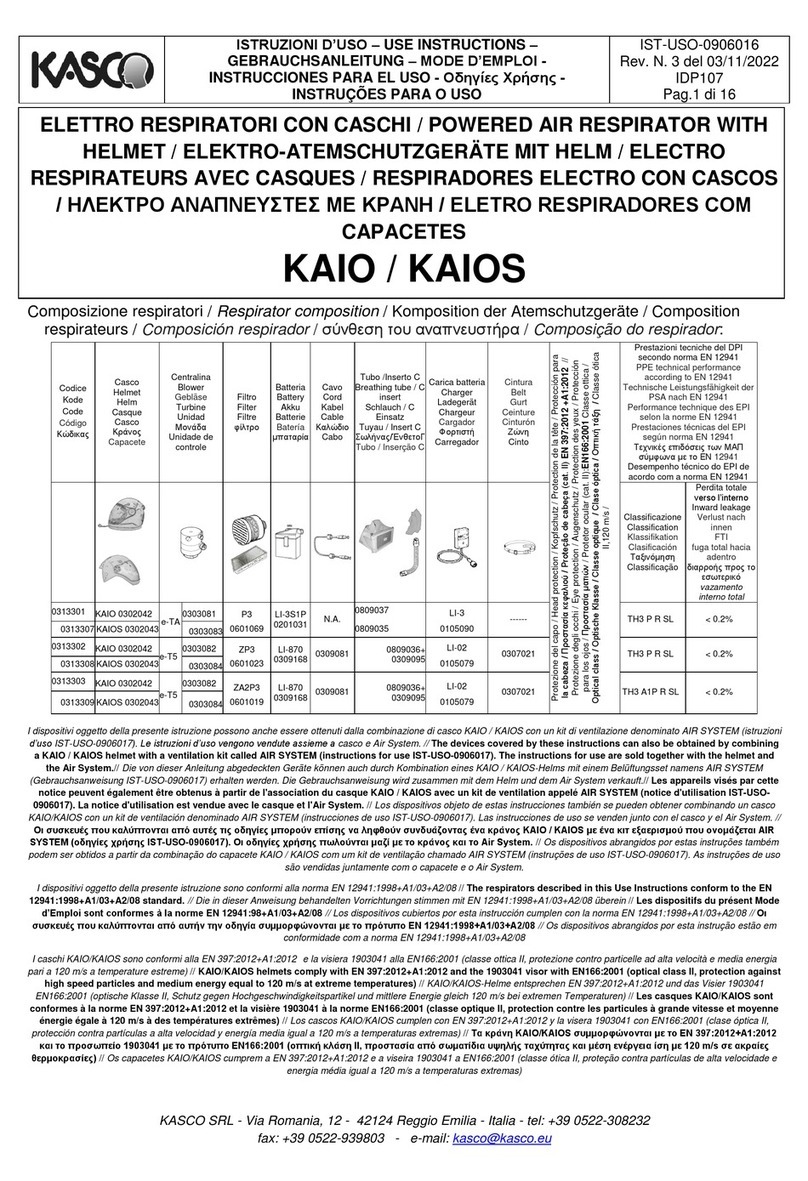

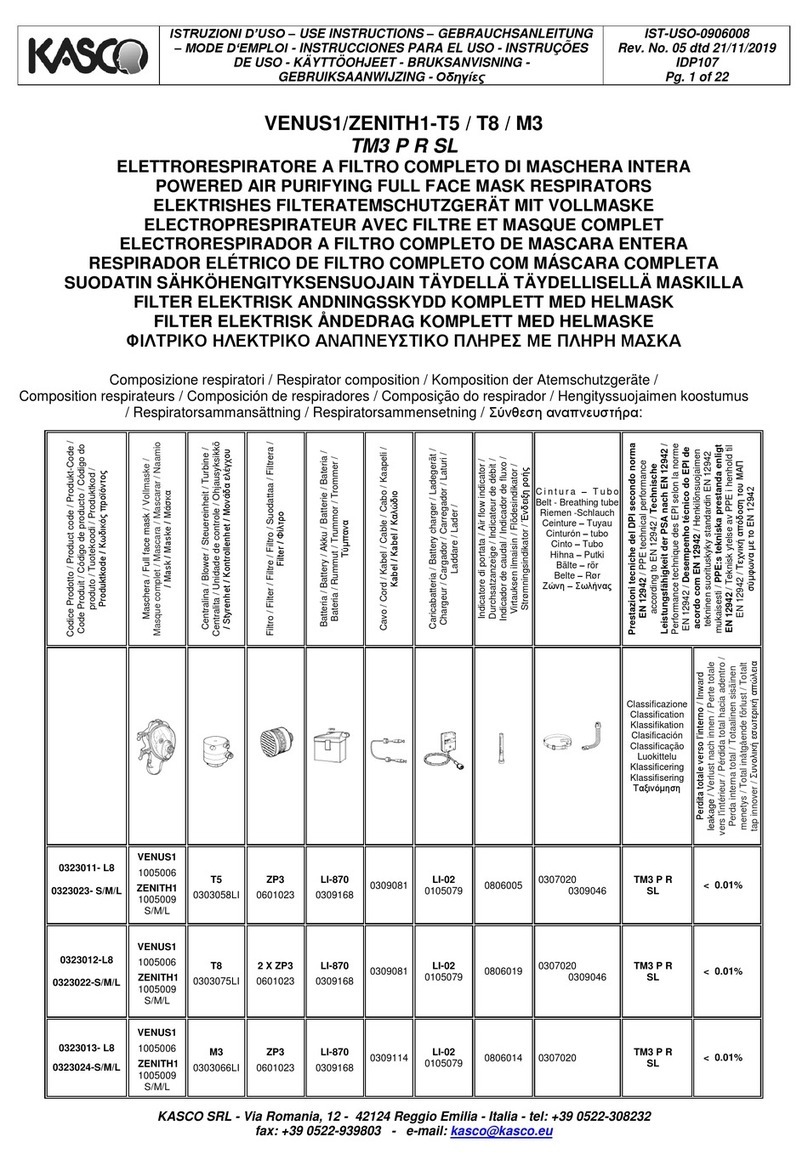

9.1 Review the respirator composition chart/Niosh approval label found inside the

respirator packaging and ensure that the respirator is composed of the correct sub

assemblies before use.

9.2 Kasco retains any type of warranty forfeited on the instant and declines any liability

either direct or indirect should these User’s Instructions not be adhered to and

should filters and spares other than genuine Kasco filters and spare be used.

9.3 Product liability for the proper operation of the respirator is irrevocably transferred

to the purchaser or operator if:

a) the prescribed maintenance is not carried out and/or if repairs and

maintenance are carried out on the respirator by personnel not employed by

or service centers not authorized by KASCO.

b) the respirator is used in a manner not conforming to its intended use as

specified in the relative product certification/approval.

9.4 IMPORTANT: Adhere strictly to all instructions, labels and limitations pertaining to

this equipment. If instructions and warning are not adhered to at all times,

respirator effectiveness will diminish and wearer protection will be reduced.

LIMITED PRODUCT WARRANTY

KASCO, as manufacturer, warrants to the original purchaser, each product of its own manufacture, for a period of one year from its date of shipment from the factory, to be free from defects in material and workmanship

under normal use and service.

Normal use and service is intended as all the operations specified in the applicable instruction manuals.

This warranty does not apply to any product which has been repaired or altered to adversely affect the performance or reliability of the respirator or other product.

This warranty does not apply to filters and furthermore does not apply to motors and batteries, the expected life or cycle of which is stated, whenever possible, in the relative instructions manuals.

Neither this warranty nor any implied warranty applies to damage or harm caused by any or all of the following:

1. Freight damage

2. Damage caused by parts and/or accessories or components not obtained from or approved by KASCO.

3. Damage due to misapplication and/or misuse.

The liability of KASCO under the foregoing warranty is limited to the repair or replacement at KASCO’s option without charge for labor or materials of any part upon return of the entire respirator or other product or of the

particular part to the KASCO factory within the warranty period, at the sole expense of the purchaser, which part shall upon examination appear to the satisfaction of KASCO to have been defective in material or

workmanship.

KASCO expressly warrants its products as above stated.

Any other intervention on products returned will be charged at the prices in force.

This warranty does not cover labor expenses for products returned to KASCO within the warranty period for checks or repairs under warranty if said products are found to be in good working order.

No person including any dealer or representative of KASCO is authorized to make any representation or warranty concerning KASCO products on behalf of KASCO or to assume for KASCO the obligations contained in

this warranty.

KASCO reserves the right to make changes in design and other changes and improvements upon its products without imposing any obligations upon itself to install the same, upon existing products or products then in

the process of manufacture.

Products returned to KASCO for repairs or replacement shall contain the series or lot number originally affixed to the product at the time of production.

Kasco srl Via Romania, 12 - 42124 Reggio Emilia - Italy - Tel: 39-522-308232/391032 - Fax: 39-522-939803

e-mail: kasco@kasco.eu - web: www.kasco.eu