*1: For instructions on adjusting the settings, see the separate “N-21 Series Network Manual”.

Network-related errors indicate errors in access between the main unit and network. In some cases they are related to the

network system, so consult the network administrator. If the problem persists, it may be due to a main unit malfunction.

Contact your store of purchase.

SPECIFICATION

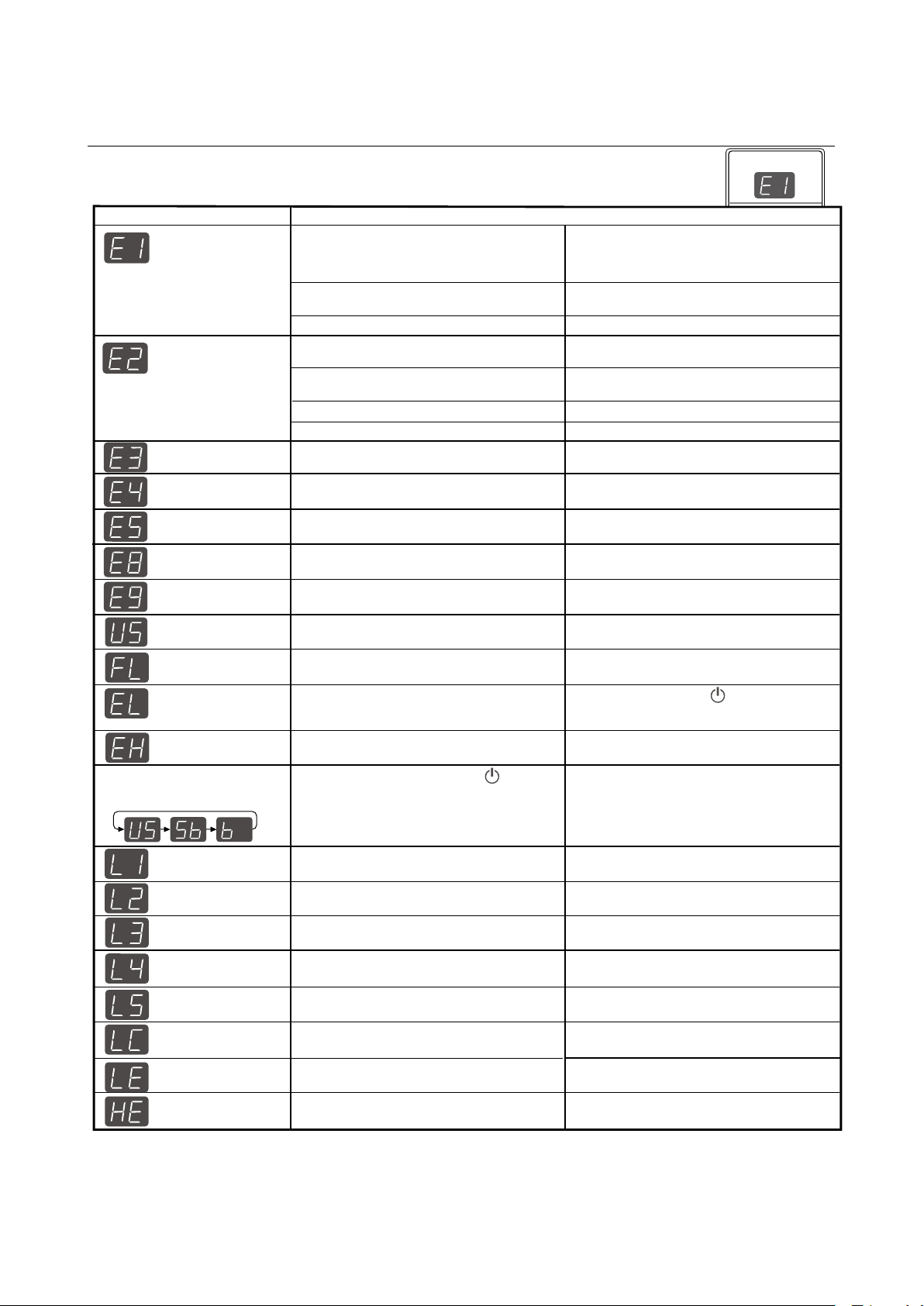

2-5. Meaninig of Error Messages

If any of the following ashing indications appear in the display window of the control panel, please check

the matters described below. Error messages ash for 5 seconds, then stop ashing, remaining lit.

Problem and Solution

• Is the printer cable connected?

• Is power being supplied to the printer?

• When the printer uses an AC power ada-

pter, is the cable disconnected somewhere?

•

Check if the settings for FTP printing are

correct.

*1

• Has paper been set in the printer?

•

Is the printer error indicator ashing (or lit)?

• Is the USB memory unformatted.

• Is a USB memory that is not supported

by the main unit being used?

•

An error occurred during memory storage.

•

There is a lighting fault of the reading light

source, or a read signal error.

•

The operation is set to “Disable” in the

security settings.

• There is a memory or internal fault.

• Coloring printing is set to “Disable”.

• USB memory device is not plugged

into the main unit.

• There is no available space.

•

A printer that is not supported by the

main unit has been connected.

•

Did you press the ON/Standby button

while the USB memory device was plugged

into

the main unit?

•

A USB memory device is plugged into the

main unit. When the USB memory device

is disconnected, the power will be

switched

off and the unit will enter the standby mode.

•

An error has arisen when setting the

time.

•

Unplug the power plug from the power

outlet and then plug it in again.

• Unplug the power plug from the power

outlet and then plug it in again.

•

Change the setting of the desired item to “Enable”.

(Refer to the separate "N-21 series Network Manual")

• Connect the LAN cable properly.

•

Input the correct values.*1

•

No cable is connected to the LAN terminal.

• The account name or password in the

FTP settings is wrong.

• The FTP server’s IP address is wrong.

• There is no FTP storage folder.

• An error other than one indicated by L1

to L4 has occurred.

• The FTP printing error has occurred.

• An error has occurred in resetting the

network settings.

• This occurs when the size of the inserted

image is too large.

• Consult your network administrator, then

marke the proper settings.

*1

• Consult your network administrator, then

marke the proper settings.

*1

• Unplug the power cord from the power

outlet then plug it back in.

•

The network reset number is wrong. Input the

correct number and repeat the operation.

*1

•

Adjust the image then repeat the operation.

•

C

hange the color printing setting to “Enable”.

•

Plug the USB memory device into the

USB port.

•

Please delete unnecessary data using

a personal computer.

•

Start over and set the proper date

and time

.

•

Press the ON/Standby button and switch

off the power. When a record is required,

switch on the power and save to USB memory.

•

Is the USB memory device plugged in fully?

• Is the USB memory damaged? —

•

This unit supports the FAT and FAT 32 formats.

Perform the formatting with the personal computer.

•

The le formats for USB memory devices that

can be used on this copyboard areFAT and FAT32.

•

Please check the operation with a personal computer.

•

Please perform memory storage again.

•

Do not insert or remove the USB memory during processing.

Printer not conne-

cted

No printing

paper Printer

problem

USB Memory

not recognized

Memory stage

problem

Reading problem

System error

USB memory not

connected

Memory is full

Security

protection

Color printing

prohibited

LAN cable discon-

nected

FTP server recognition

error

FTP server

connection

failure

Network settings

reset error

Header/footer

writing error

FTP server writing

failure

IP address not set,

other network error

FTP printing error

Time setting error

When the “USB” letter display is

owing...Warning that disconnection

of USB memory has been forgotten

An unsupported

printer is conne-

cted

•

Connect the printer properly and sw-

itch on the printer power.

•

Turn the power of the printer off and then on again,

and load the printer with A4 or Letter size paper.

• Read the printer instruction manual.

Error Display Number