DESCRIZIONE: I dispositivi di protezione individuale di categoria III

“FORZA ø10mm”, “FORZA ø10,5mm” e “FORZA ø11mm” sono:

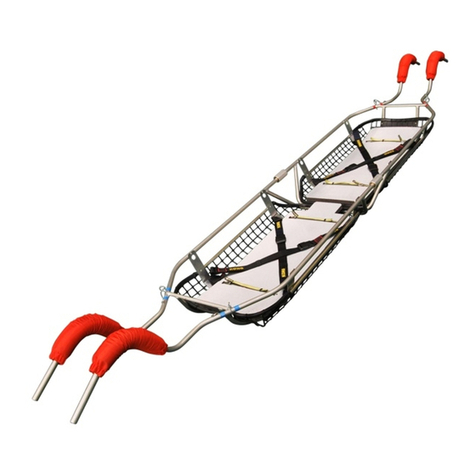

- corde KernMantel a bassa elasticità (corde semi-statiche) proget-

tate per accesso su corda, in speleologia, soccorso in quota e altre

attività simili (salita e discesa combinata di persone, dispositivo di

sicurezza per il posizionamento sul lavoro con accesso su corda,

soccorso con discesa e sollevamento di persone, come mezzo per

la salita, discesa e il movimento orizzontale in speleologia);

- parte di un sistema di protezione contro gli urti causati dalle cadute

dall’alto;

- certicati secondo la norma EN 1891:1998 tipo A.

TAGLIO: Ogni estremità di questo dispositivo è troncata dal pro-

duttore con una specica tecnica di nitura: l’anima e la calza sono

collegate in un’unica unità compatta negli ultimi 15 mm della lun-

ghezza della corda.

Se l’utilizzatore taglia questo dispositivo, la corda deve essere tron-

cata in modo che l’anima e la calza formino un’unica unità (ad esem-

pio, fondendo le estremità con un bruciatore ad alcool o tagliando le

estremità con una lama calda). Entrambe le estremità non devono

avere spigoli vivi e devono essere dotate di nastri esterni riportanti

le seguenti informazioni:

- numero della norma: EN 1891;

- diametro della corda in mm, esempio: 10,5 mm;

- tipo di corda A o B secondo la norma EN 1891:1998.

1 - INFORMAZIONI GENERALI

A) Prima di utilizzare il dispositivo, l’utilizzatore deve leggere e com-

prendere correttamente le informazioni fornite dal produttore (di

seguito “informazioni”).

Attenzione:

- Queste informazioni riguardano le caratteristiche, i servizi, il

ssaggio, lo smontaggio, la manutenzione, la conservazione,

la disinfezione, ecc. del dispositivo;

- Sebbene le presenti informazioni includano alcuni sugge-

rimenti sule modalità di utilizzo del dispositivo, queste non

devono essere considerate vere e proprie istruzioni per l’uso

(così come un manuale d’uso e manutenzione di un’auto non

insegna a guidare e non sostituisce una scuola guida);

- L’arrampicata su roccia o su ghiaccio, la discesa in corda

doppia, la via ferrata, la speleologia, lo sci alpino, il torrenti-

smo, l’esplorazione, le operazioni di soccorso, l’arrampicata su

albero e i lavori in quota sono tutte attività a elevato alto grado

di rischio, che possono essere causa di incidenti e persino di

morte. L’utilizzatore è totalmente responsabile dei rischi deri-

vanti da tali attività e dall’utilizzo del nostro dispositivo;

- Il presente dispositivo deve essere utilizzato solo da perso-

ne in condizioni mediche idonee che siano state addestrate (e

istruite) sul suo utilizzo, o sotto il diretto controllo di istruttori/

supervisori che ne garantiscano la sicurezza.

B) Prima e dopo l’utilizzo del dispositivo, l’utilizzatore deve eseguire

tutte le ispezioni descritte nelle informazioni speciche e, in partico-

lare, deve accertarsi che il dispositivo sia:

- in perfette condizioni e perfettamente funzionante;

- idoneo all’uso: sono ammesse solo le operazioni non contrasse-

gnate; ogni altro uso è considerato improprio e quindi potenzialmen-

te pericoloso.

C) Se l’utilizzatore ha il minimo dubbio sull’efcienza del dispositi-

vo, lo deve sostituire immediatamente, in particolare dopo averlo

utilizzato per arrestare una caduta. L’uso non conforme, le deforma-

zioni, le cadute, l’usura, la contaminazione chimica, l’esposizione a

temperature inferiori a -30°C o superiori a +50°C per i componenti/

dispositivi tessili/plastici, e +100°C per i dispositivi metallici, sono

alcuni esempi di altre cause che possono ridurre, limitare e termi-

nare la vita del dispositivo. E’ vivamente consigliato l’uso personale

del dispositivo per mantenere continuamente monitorati il grado di

protezione e di efcienza.

D) Questo dispositivo può essere utilizzato in abbinamento ad altri

dispositivi quando compatibili con le informazioni rilevanti dei fab-

bricanti.

E) La posizione dell’ancoraggio è fondamentale per la sicurezza

dell’arresto della caduta:

valutare attentamente l’altezza libera presente sotto l’utilizzatore,

l’altezza di una potenziale caduta, l’allungamento della corda/fune,

l’allungamento di un eventuale assorbitore/dissipatore di energia, la

statura dell’utilizzatore e l’effetto “pendolo”in modo da evitare ogni

possibile ostacolo (es. il terreno, lo sfregamento, le abrasioni, ecc.).

F) La resistenza minima dei punti di ancoraggio, realizzati sia su

elementi naturali che articiali, deve essere di almeno 12 kN. La

valutazione di quelli realizzati su elementi naturali (roccia, vegetali,

ecc.) è possibile solo in modo empirico, per cui deve essere effet-

tuata da persona esperta e competente, mentre per quelli realizzati

su elementi articiali (metalli, calcestruzzo, ecc.) è possibile in modo

scientico, pertanto deve essere effettuata da persona qualicata.

G) E’ assolutamente vietato modicare e/o riparare il dispositivo.

H) Evitare l’esposizione del dispositivo a fonti di calore e al contatto

con sostanze chimiche. Ridurre al necessario l’esposizione diretta

al sole, in particolare per i dispositivi tessili e plastici. A temperature

basse e in presenza di umidità può formarsi del ghiaccio che, sui

dispositivi tessili, può ridurre la essibilità e aumentare il rischio di

taglio e abrasione.

I) Vericare che il dispositivo sia stato fornito integro, nella confe-

zione originale e con le relative informazioni del fabbricante. Per

i dispositivi venduti in paesi diversi dalla destinazione di origine, il

rivenditore ha l’obbligo di vericare e di fornire la traduzione di que-

ste informazioni.

L) I nostri dispositivi di protezione individuale vengono certicati da

organismi accreditati indicati nelle istruzioni speciche del disposi-

tivo e sono inoltre soggetti alla sorveglianza sulla produzione - ai

sensi degli allegati V e VIII del Regolamento (UE) 2016/425 - da

parte di un organismo il cui numero di accreditamento è indicato

sul dispositivo.

Attenzione: i test di laboratorio, le ispezioni, le informazioni e

le norme non sempre riescono a riprodurre ciò che accade nel-

la pratica, per cui le condizioni di utilizzo reali in un ambiente

naturale possono differire, a volte anche sensibilmente. Infor-

mazioni ottimali possono essere ottenute attraverso la pratica

continua sotto la supervisione di personale competente, esper-

to e qualicato.

2 – LAVORI IN QUOTA

Informazioni aggiuntive per i sistemi individuali di protezione contro

le cadute dall’alto.

Ai ni della sicurezza contro le cadute dall’alto è essenziale:

- effettuare la valutazione dei rischi ed accertarsi che l’intero siste-

ma, di cui questo dispositivo è solo un componente, sia afdabile

e sicuro;