All Specifications are subject to change without prior notice.

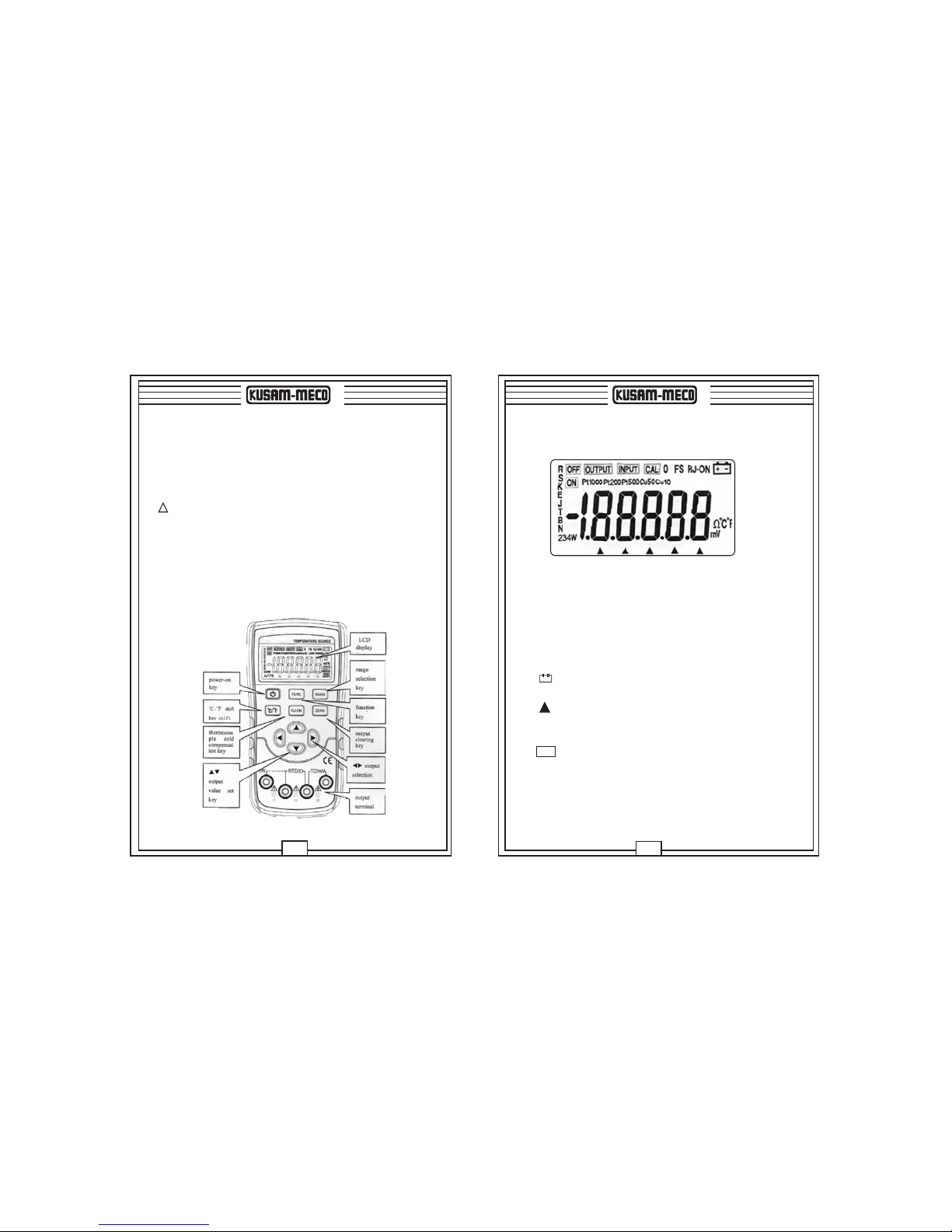

TEMPERATURE CALIBRATOR

Preliminary Data

An ISO 9001:2008 Company

G-17, Bharat Industrial Estate, T. J. Road, Sewree (W), Mumbai - 400 015. INDIA.

Sales Direct.: 022-24156638, Tel. : 022-24124540, 24181649, Fax : 022-24149659

An ISO 9001:2008 Company

®

Chhaya com/D/chhaya/my documents/chhaya/backup/catlog/New catlog/2015 new arrival catalogs/KM-CAL-801.cdr

Model KM-CAL-801

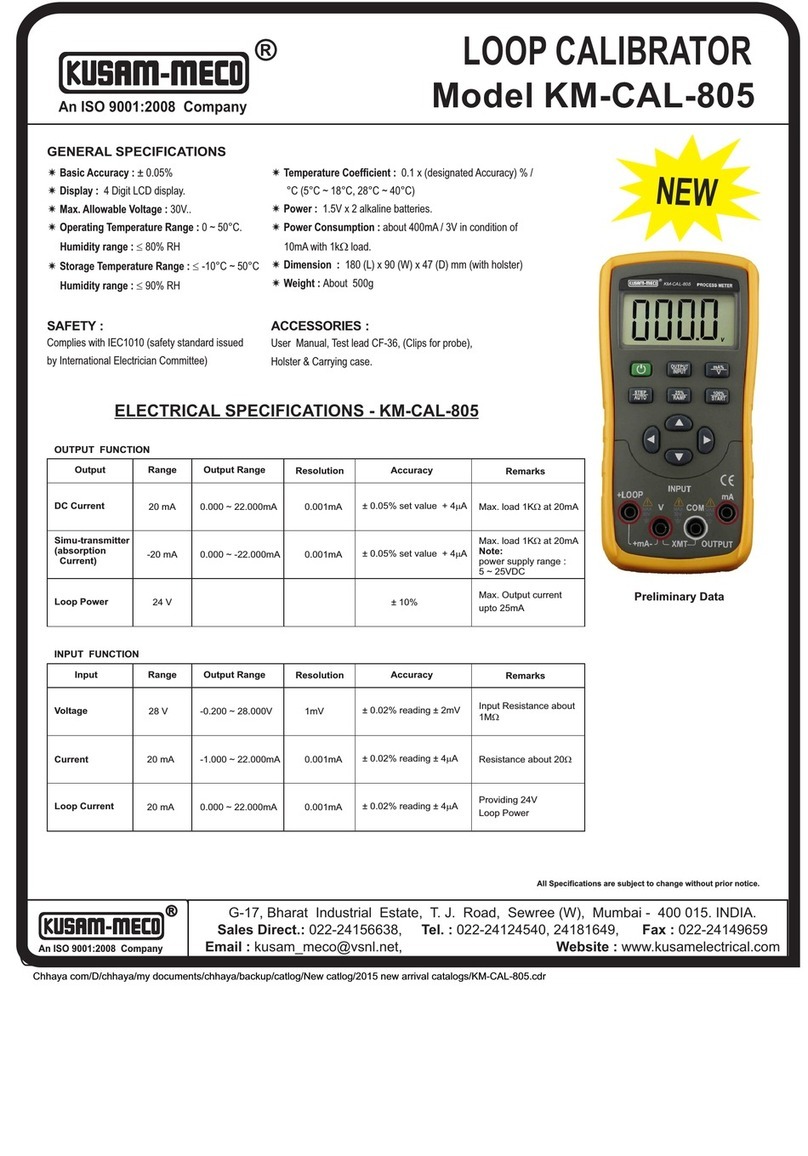

ELECTRICAL SPECIFICATIONS - KM-CAL-801

í Basic Accuracy : ± 0.05%

í Display : 5 Digit LCD display.

í Max. Allowable Voltage : 30V..

í Operating Temperature Range : 0 ~ 50°C.

Humidity range : £ 80% RH

í Storage Temperature Range : £ -10°C ~ 55°C

Humidity range : £ 90% RH

GENERAL SPECIFICATIONS

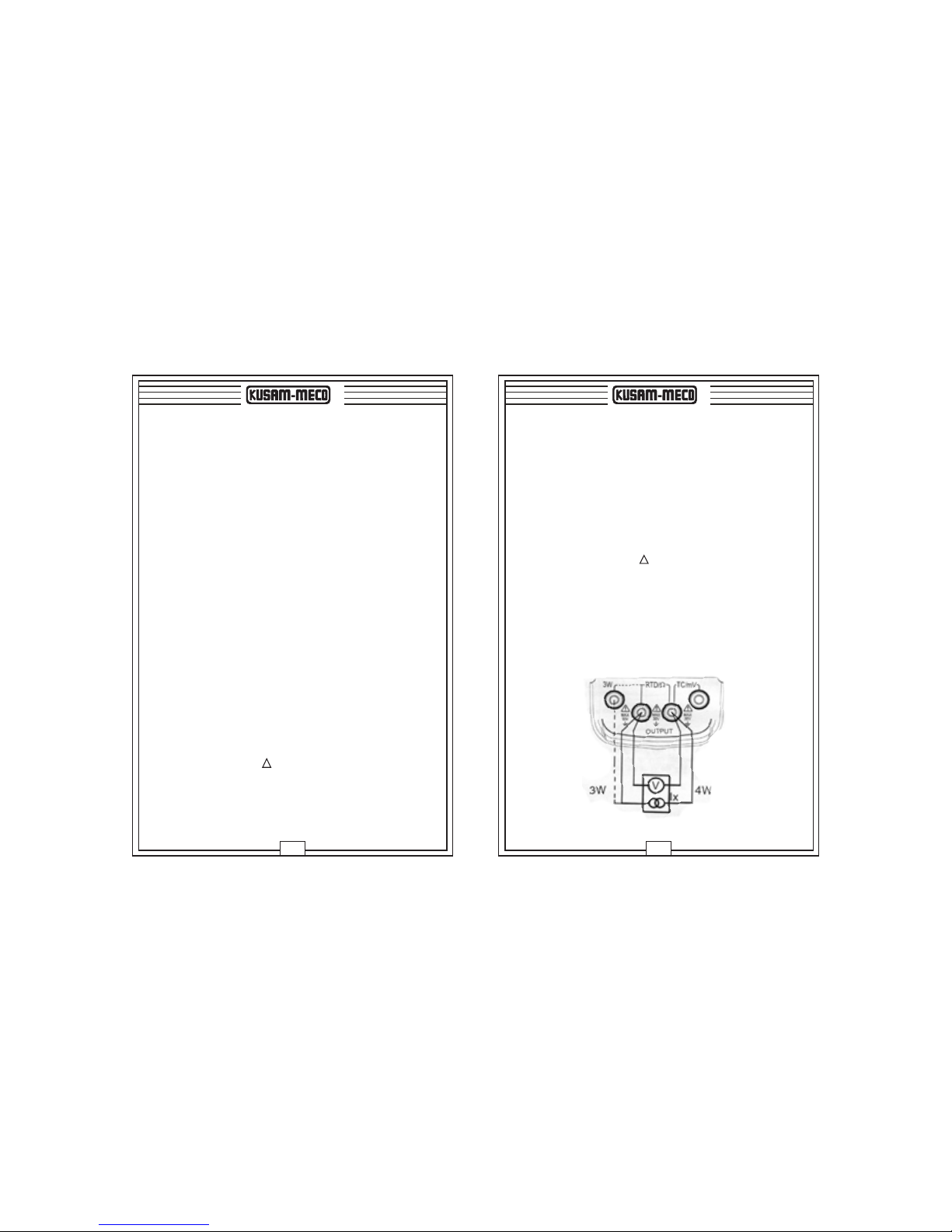

This Calibrator is a source for Volts, Ohms RTD & Thermocouples. It gives output

of Volts in 2 ranges 100mV & 1000mV & also gives output of Ohms in 2 ranges

400W & 4000W & output for calibrating R, S, B, E, K, J, T & N type Thermocouples.

It also gives output for RTD Pt1000 & Cu50. It has very high accuracy 0.05%.

í Temperature Coefficient : 0.1 x (dedicated Accuracy) % /

°C (5°C ~ 18°C, 28°C ~ 40°C)

í Power Consumption : about 60m / 3V.

í Dimension : 180 (L) x 90 (W) x 47 (D) mm (with protector)

í Weight : About 500g

í Power : 1.5V x 2 alkaline batteries.

ACCESSORIES :

User Manual, Test lead CF-36, (Clips for probe),

Holster & Carrying case.

SAFETY :

Complies with IEC1010 (safety standard issued

by International Electrician Committee)

NEW

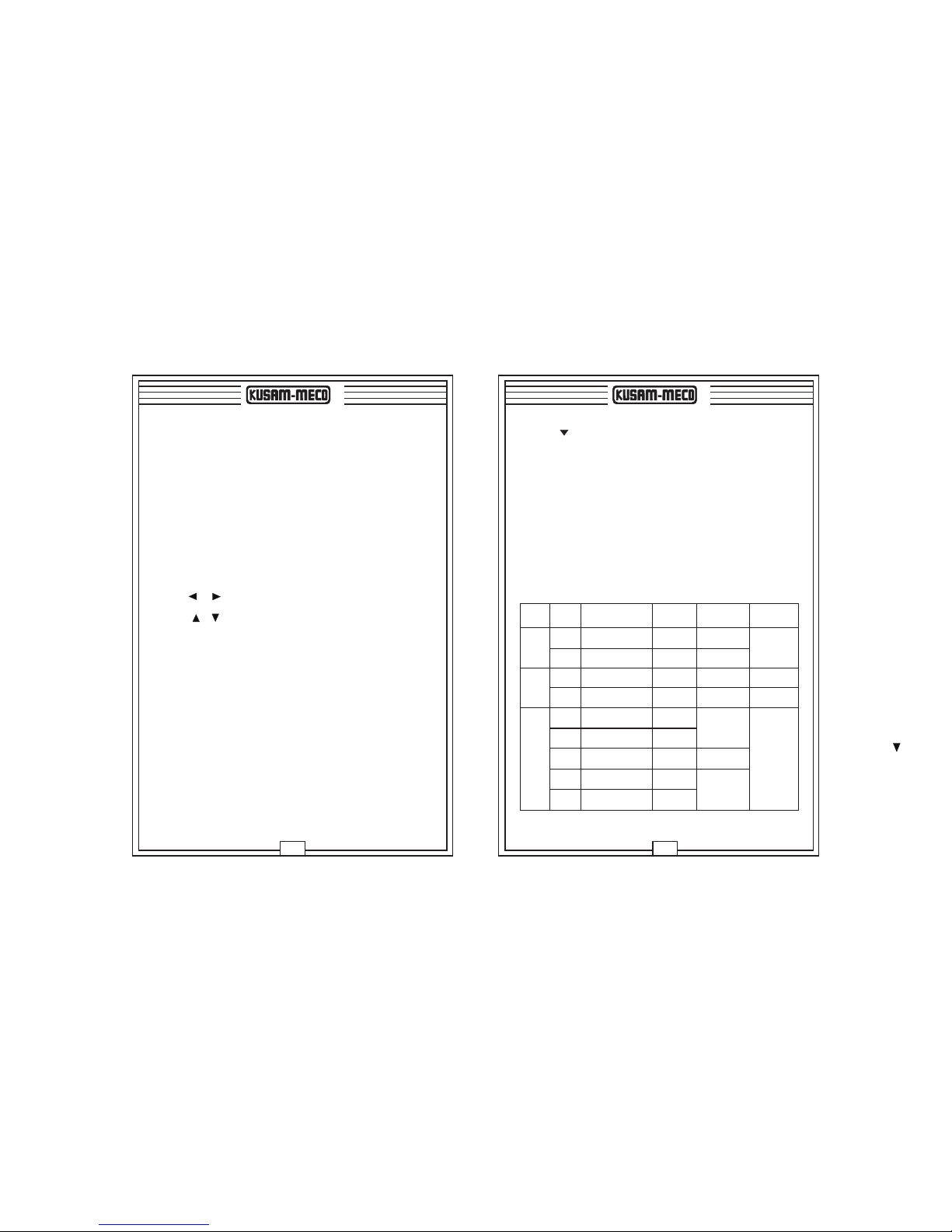

OUTPUT FUNCTION

100mV -10.00 ~ 110.00mV 0.01mV ±0.05% ± 30mVThe max. Output

current ± 2mA

DC Voltage

Output Remarks

Accuracy

Output Range Resolution

Range

1000mV -100.0 ~ 1100.0mV 0.1mV ±0.05% ± 0.3mV

400W0.0 ~ 400.0W0.1W±0.05% ± 0.2W

OHM

4000W0 ~ 4000W1W±0.05% ± 2W

±0.05 ~ ±0.3mA

Affiliated resistance of test lead is excluded.

The range of incentive current is from

0.05mA to 3mA & the maximum output

is less than or equals to 2V.

R

S

B

E

K

J

T

N

O

-40 ~ 1760 C

O

-20 ~ 1760 C

O

400 ~ 1800 C

O

-200.0 ~ 1000.0 C

O

-200.0 ~ 1370 C

O

-200.0 ~ 1200.0 C

O

-200.0 ~ 400.0 C

O

-200.0 ~ 1300.0 C

O

1 C

O

1 C

O

1 C

O

0.1 C

O

0.1 C

O

0.1 C

O

0.1 C

O

0.1 C

±0.05% + 3°C

O

(Less than or equals to 100 C)

O

±0.05% + 2°C (more than 100 C)

Employs ITS-90

temperature

standard

The accuracy does not

include the error of

interior temperature

compensation sensor

the range of interior

temperature compensation

sensor is from -10 to 50°C

& the error compensation

is less than or equals to

0.5°C

Thermo-

couple

RTD

O

±0.05% + 3°C (400 ~ 600 C)

O

±0.05% + 2°C (more than 600 C)

±0.05% + 2°C

O

(Less than or equals to -100 C)

±0.05% + 1°C

O

(more than -100 C)

Cu10

Cu15

Pt10

385

Pt100

385

Pt200

385

Pt500

385

Pt1000

385

O

-10.0°C ~ 250.0 C

O

-50.0°C ~ 150.0 C

O

-200.0°C ~ 850.0 C

O

-200.0°C ~ 850.0 C

O

-200°C ~ 630 C

O

-200.0 ~ 1200.0 C

O

-200.0°C ~ 630.0 C

O

0.1 C

O

0.1 C

O

0.1 C

O

0.1 C

±0.05% + 0.6°C

O

0.1 C

O

0.1 C

O

0.1 C

Incentive Current is

±0.5 ~ ± 3mA

When the incentive

current is ± 0.1 ~ 0.5mA,

add 0.5°C additional

error

Incentive Current is

±0.05 ~ ± 0.3mA

±0.5 ~ ±3mA

Affiliated resistance of test lead is excluded.

The range of incentive current is from

0.05mA to 3mA & the maximum output

is less than or equals to 2V.