*18782*

18782

Instructions

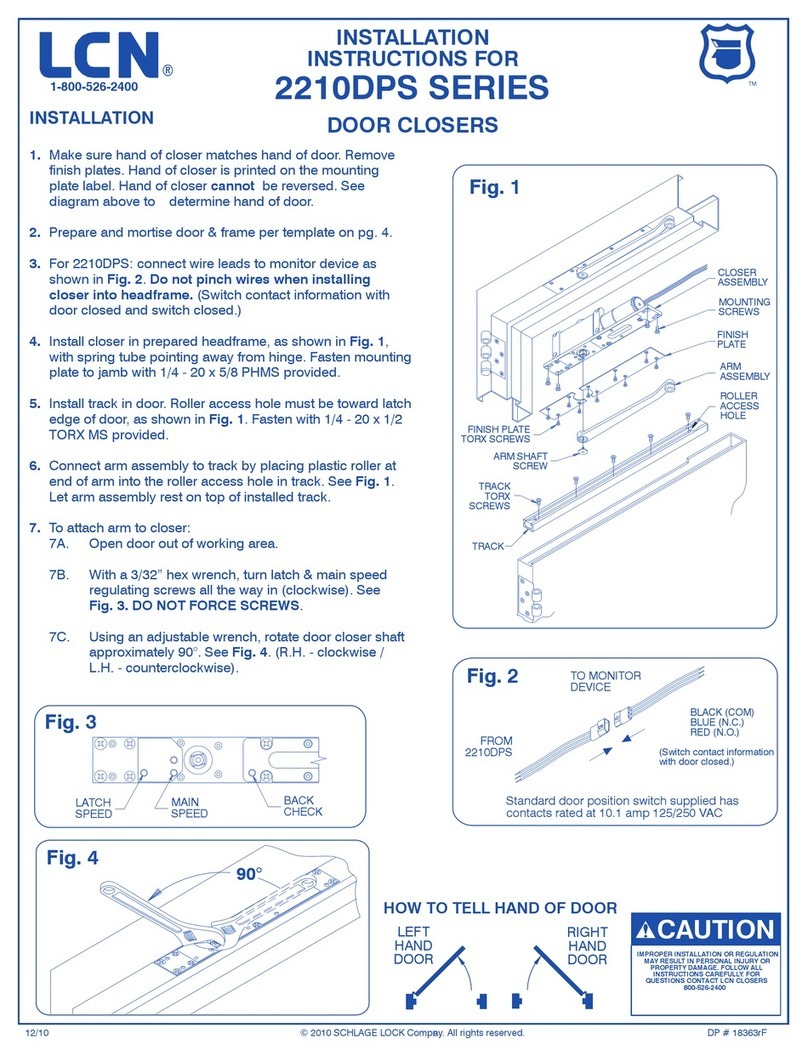

1a Closer is handed at factory and must match hand of

door. hand of closer shown on mounting channel.

Voltage shown on SENTRONIC cover plate must

match voltage supplied to door frame.

1b If door & frame are not prepared for closer & track

then prepare in accordance with details on opposite

side.

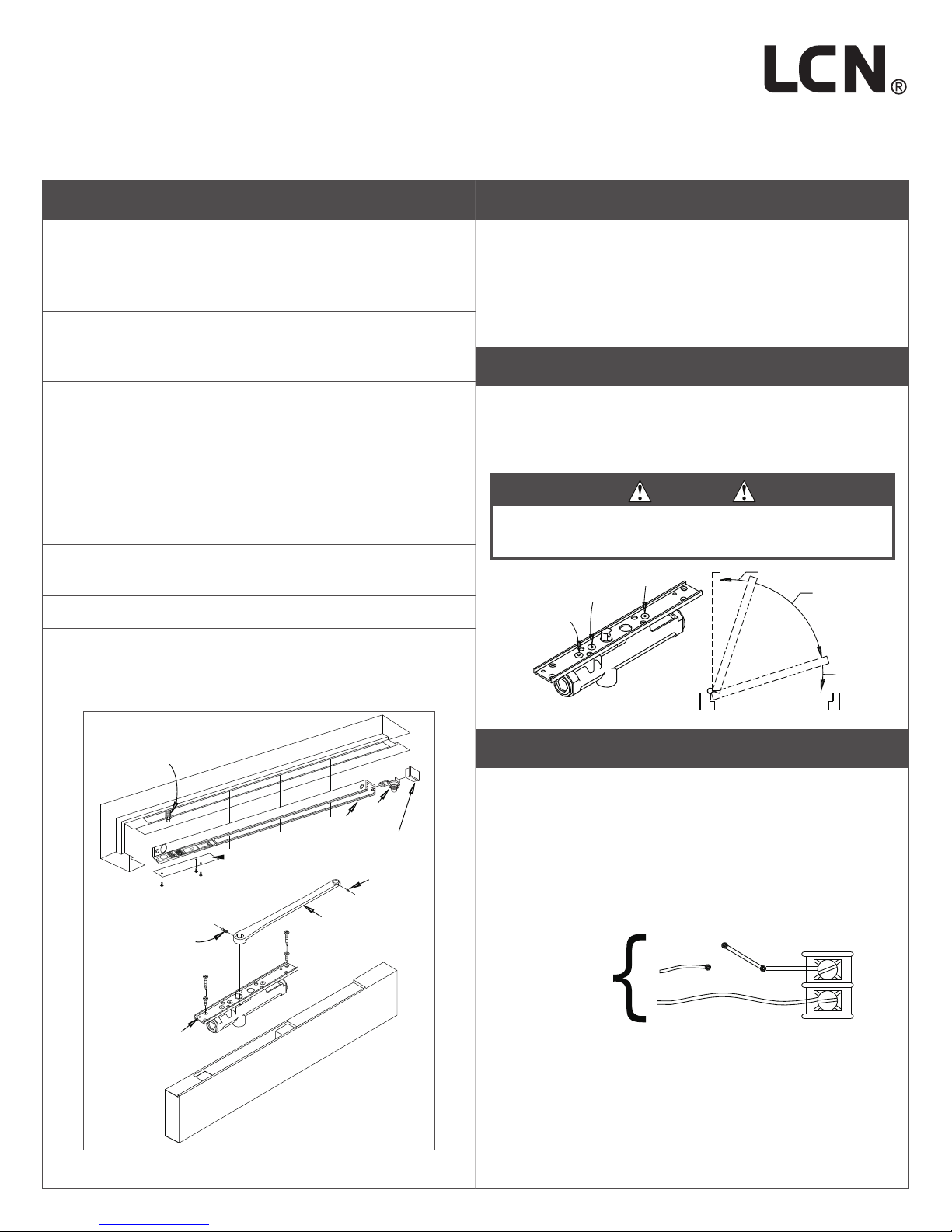

1c Remove cover plate from track. Assemble exible

conduit connector to tapped hole provided in top of

track. Connect power supply wires to track terminal

strip. See wiring diagram below. Insert track roller

into track. Make sure roller stud is inserted into hole

in track slide. Insert track into frame and secure with

proper screws as shown on opposite side. Replace

cover plate.

1d Insert closer in cut out in door & secure with proper

screws.

1e Place arm on closer shaft and secure with shaft screw.

1f Loosen set screw in end of arm, open door part way

(about 30°), pull arm away from top of door and

connect to track roller. Tighten set screw rmly. Open

door to hold open position.

Backcheck

Main

Speed

Latch

Speed

Backcheck

Main Speed

Latch Speed

Door

Closer

Shaft Screw

Arm

Set Screw

Cover

Plate

Track

Optional Concealed Flexible

1/2” Conduit Or 12V Or 24V

Concealed Wiring

To Either Terminal

To Either Terminal

Optional Switch

Input Voltage

12V AC/DC

24V AC/DC

or

115V AC/DC

(Usually from

alarm panel

or detector) Polarity Not Important

Roller

End Cap

Regulation

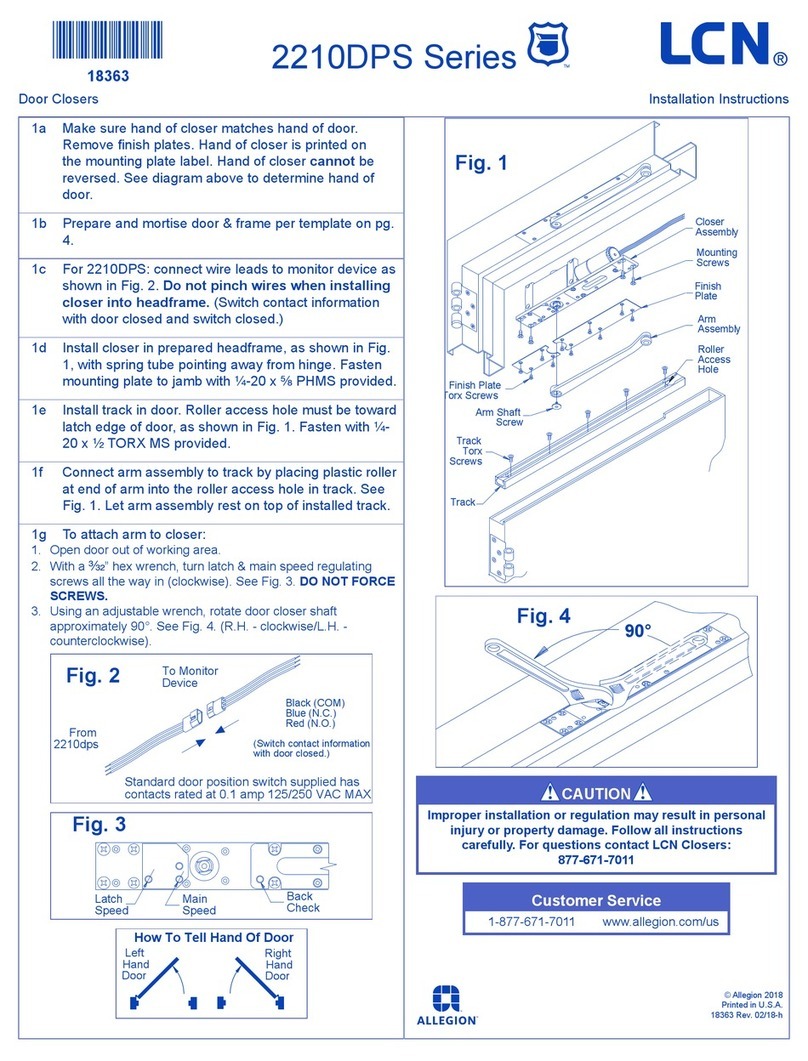

LImportant

Do not allow door to slam into frame. A “normal” closing time

from 90° open position is 5 to 7 seconds, evenly divided between

main swing speed and latch swing speed. Use socket screw key

furnished. To slow MAIN SPEED of door, turn regulating screw

(nearest arm) clockwise. To slow LATCH SPEED of door, turn

regulating screw (nearest hinge) clockwise.

Backcheck

To increase BACKCHECK, turn regulating screw (nearest latch)

clockwise. Use lightest BACKCHECK that will retard door opening

sufciently.

DO NOT ABRUPT BACKCHECK NOR EXPECT DOOR CLOSER

TO ACT AS A STOP

CAUTION

Improperly installed or regulated closers can cause

property damage or personal injury. Please follow these

instructions carefully.

Main

Speed

Latch

Speed

Backcheck

Main Speed

Latch Speed

Door

Closer

Shaft Screw

Arm

Set Screw

Cover

Plate

Track

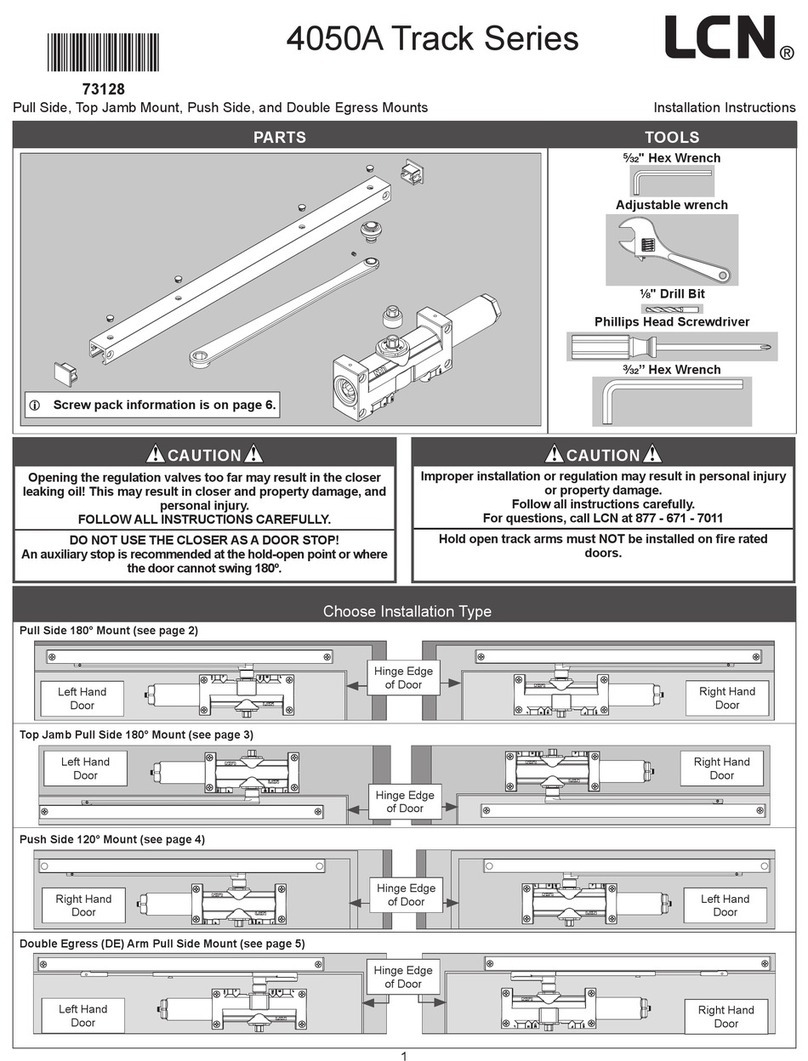

Optional Concealed Flexible

1/2” Conduit Or 12V Or 24V

Concealed Wiring

To Either Terminal

To Either Terminal

Optional Switch

Input Voltage

12V AC/DC

24V AC/DC

or

115V AC/DC

(Usually from

alarm panel

or detector) Polarity Not Important

Roller

End Cap

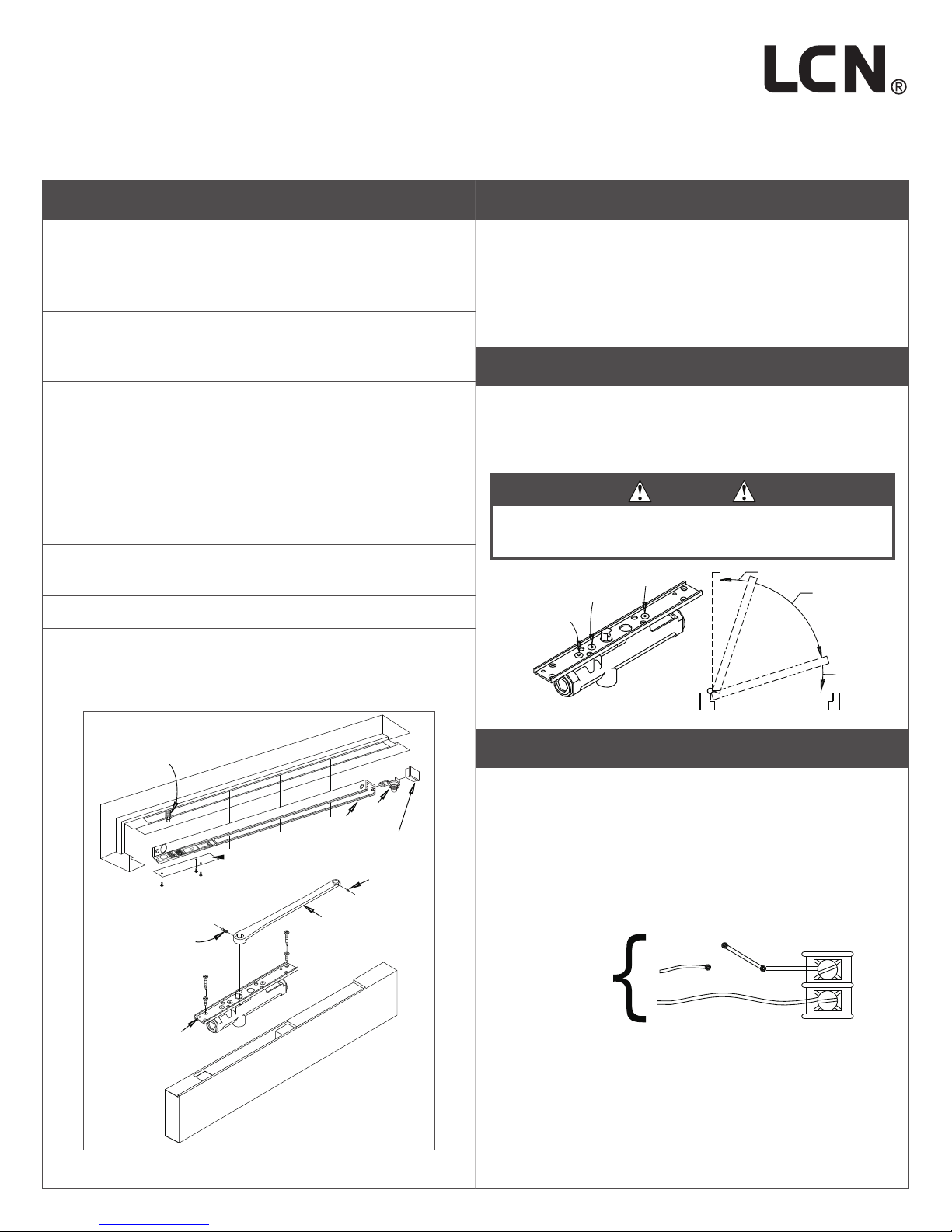

Electrical Checkout

1. With power on, open door fully. Door should remain in open

position. If door does not stay open check electrical input.

2. Turn power off. Door should close immediately. Turn power on

and leave door in the open position.

3. System should be checked at frequent intervals. It is

suggested that steps 1 & 2 be repeated every 90 days.

LNote: If door does not close when power is off, consult

LCN Representative or factory.

Backcheck

Main

Speed

Latch

Speed

Backcheck

Main Speed

Latch Speed

Door

Closer

Shaft Screw

Arm

Set Screw

Cover

Plate

Track

Optional Concealed Flexible

1/2” Conduit Or 12V Or 24V

Concealed Wiring

To Either Terminal

To Either Terminal

Optional Switch

Input Voltage

12V AC/DC

24V AC/DC

or

115V AC/DC

(Usually from

alarm panel

or detector) Polarity Not Important

LNOTE: Not for installation on Ul rated 20 minute wood core doors per can/ulc-s104-10

3130-SEL Sentronic

Installation Instructions