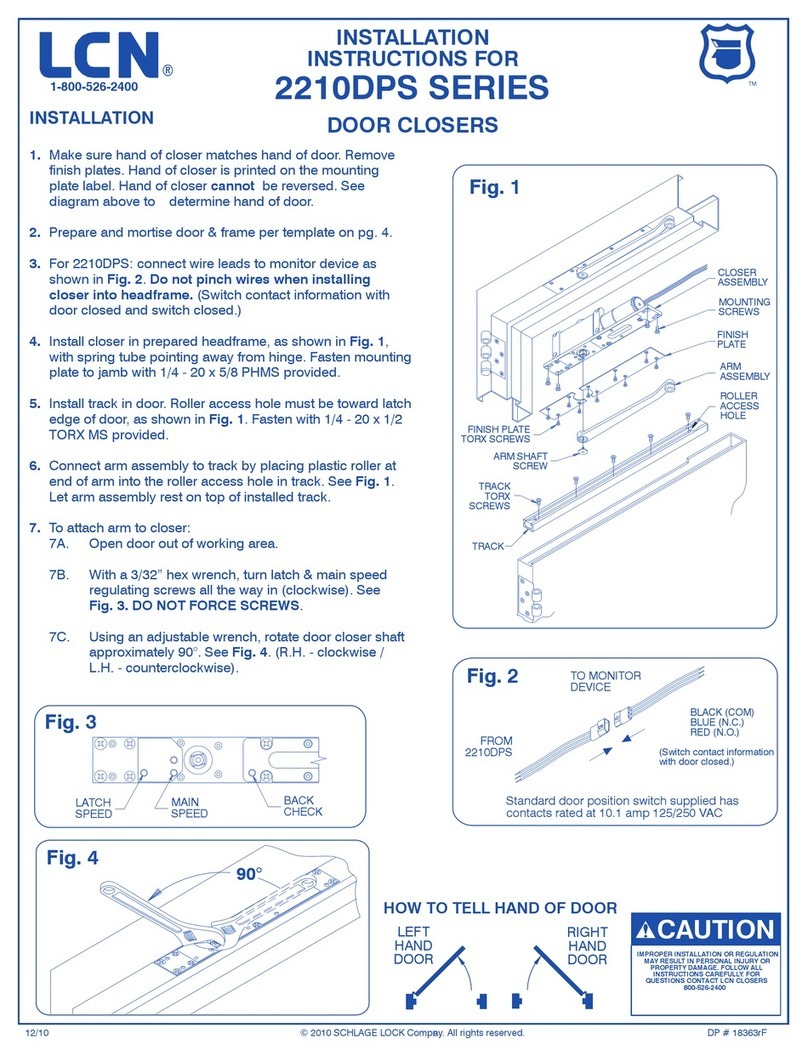

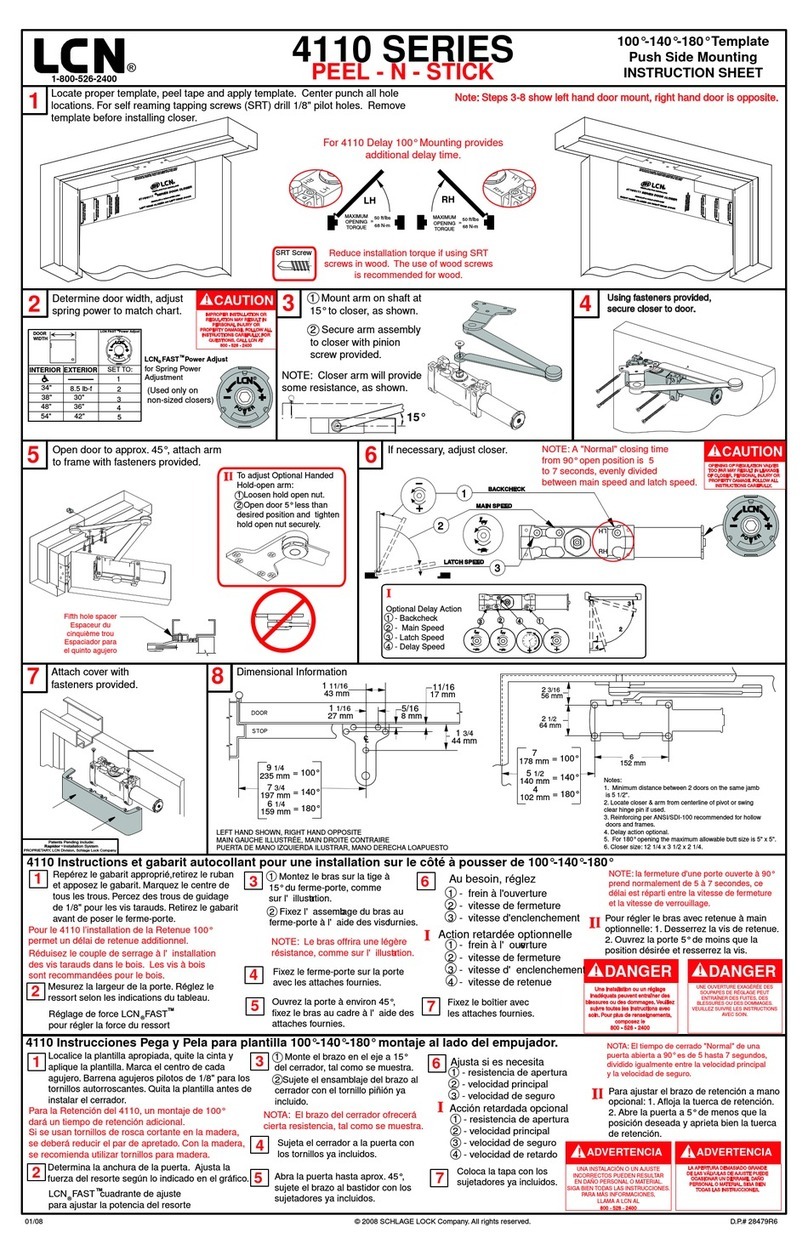

4. With closer shaft now stationary, move the end of the arm

to shaft of closer. Slowly move door so hole in arm lines up

correctly with closer shaft. Push arm up into position and insert

arm shaft screw, as shown in Fig.5.

Fig. 5

Latch

Speed

Main

Speed

Back

Check

Fig. 6

Latch

Speed

Main Speed

Backcheck

Signal Adjustment

(No. 3 Phillips Screwdriver)

Fig. 7

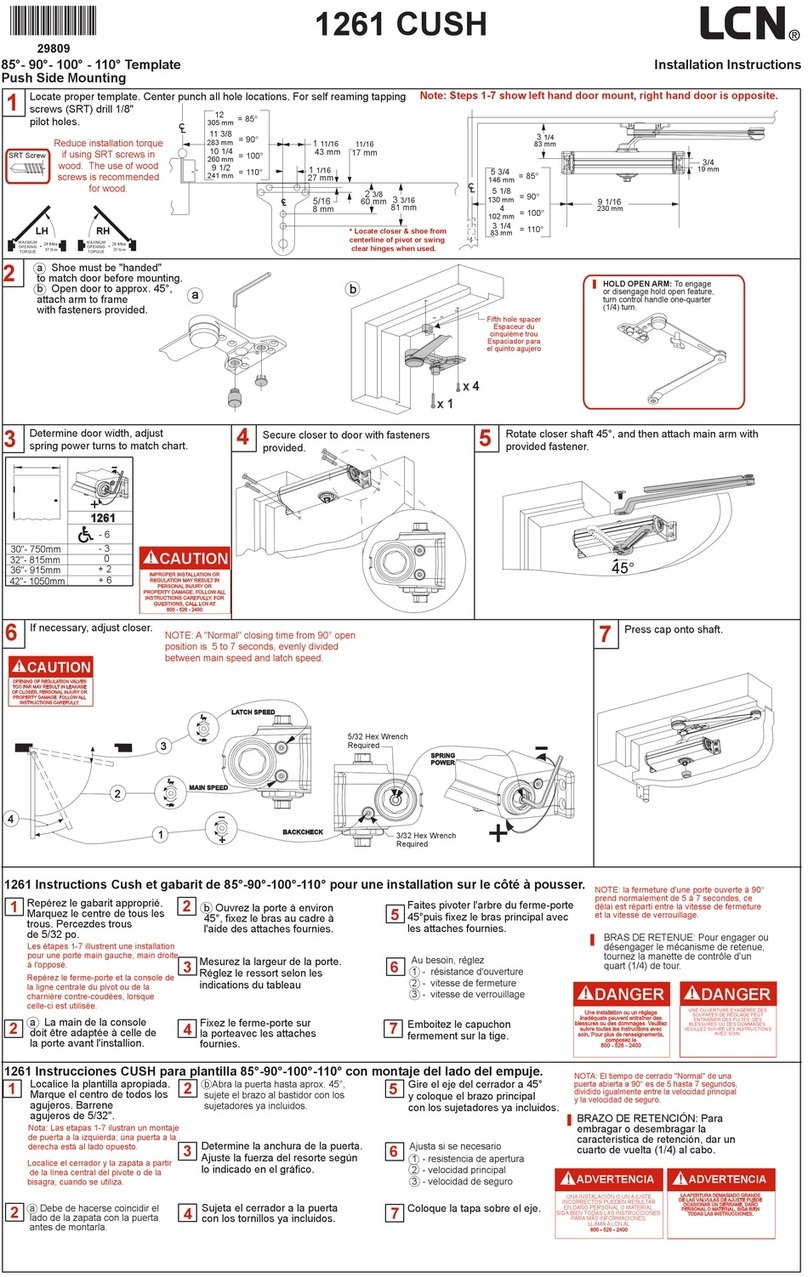

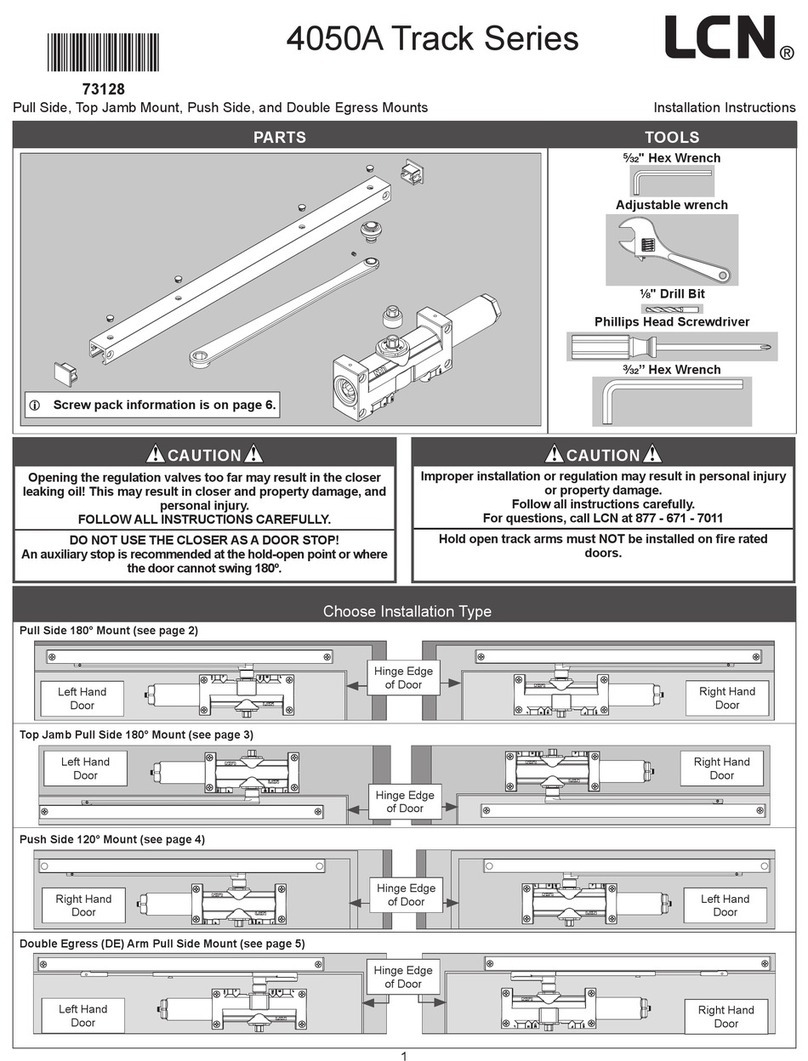

1h To Regulate Closing Speed & Backcheck: See Fig.

6 below Use a 3/32” hex wrench to re-adjust MAIN

& LATCH speed screws (closed in step 7A). Turn

both MAIN & LATCH speed screws 2 full turns

counterclockwise. Open door and observe closing

cycle. A normal closing time from a 90° position is

5 to 7 seconds, equally divided between MAIN &

LATCH speeds. If further adjustment is required,

turn regulating screws clockwise to SLOW door

speed / counterclockwise to INCREASE door speed.

BACKCHECK is a feature that slows the speed of

door at approximately 70°. To INCREASE force turn

BACKCHECK screw clockwise. To REDUCE force turn

BACKCHECK screw counterclockwise. Do not use an

abrupt BACKCHECK setting, nor expect closer to

act as a door stop!

Latch

Speed

Main

Speed

Back

Check

Fig. 6

Latch

Speed

Main Speed

Backcheck

Signal Adjustment

(No. 3 Phillips Screwdriver)

Fig. 7

Fig. 5

Latch

Speed

Main

Speed

Back

Check

Fig. 6

Latch

Speed

Main Speed

Backcheck

Signal Adjustment

(No. 3 Phillips Screwdriver)

Fig. 7

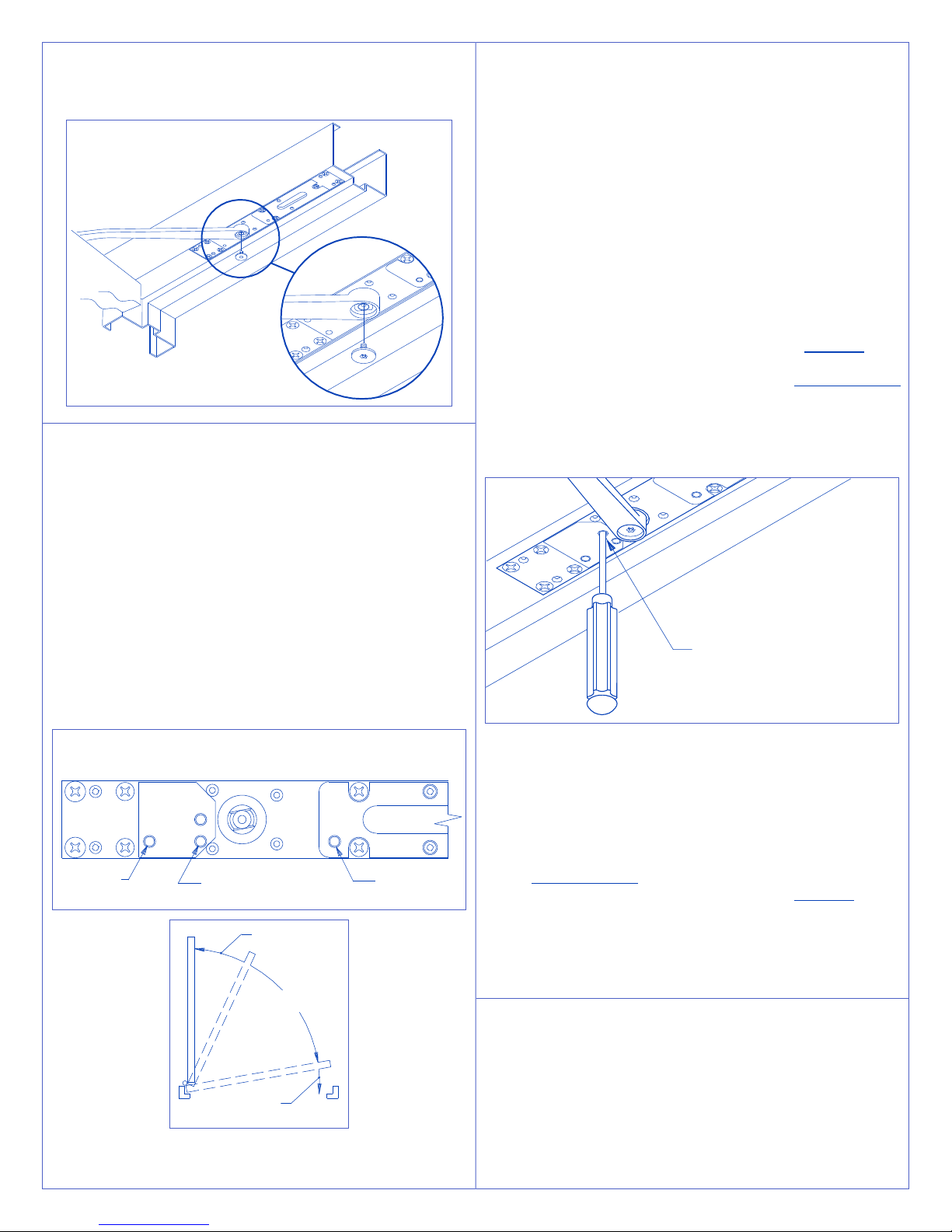

1i For 2210DPS: Signal Response Point Verication

If door silencers are to be used, they should be installed prior

to this step. Close the door slowly and note where the switch

response signal occurs. The factory setting should provide a

signal response between 1/4” & 3/4” off the stop for a 36” door.

Only if a different signaling point is necessary, perform steps a - c

using a No. 3 Phillips screwdriver (5/16” shank). If the switch is

giving an “open” signal when the door is fully closed, follow

steps 9D through 9F.

To adjust the signaling point for the door nearer to the closed

position:

a. Open the door approximately 20°, or enough to access

the signal adjustment hole in mounting plate (See Fig. 7,

below). Prevent door from moving during the adjustment.

Insert the No. 3 Phillips screwdriver into the signal

adjustment hole to engage the trigger gear.

b. For Right Hand Door: turn the screwdriver clockwise

VERY SLIGHTLY

For Left Hand Door: turn the screwdriver counterclockwise

VERY SLIGHTLY

c. REMOVE SCREWDRIVER BEFORE ALLOWING DOOR

TO MOVE. Allow the door to close completely. Check the

signal activation point. If still too far from the “door closed”

position, repeat steps a, b & c.

Fig. 5

Latch

Speed

Main

Speed

Back

Check

Fig. 6

Latch

Speed

Main Speed

Backcheck

Signal Adjustment

(No. 3 Phillips Screwdriver)

Fig. 7

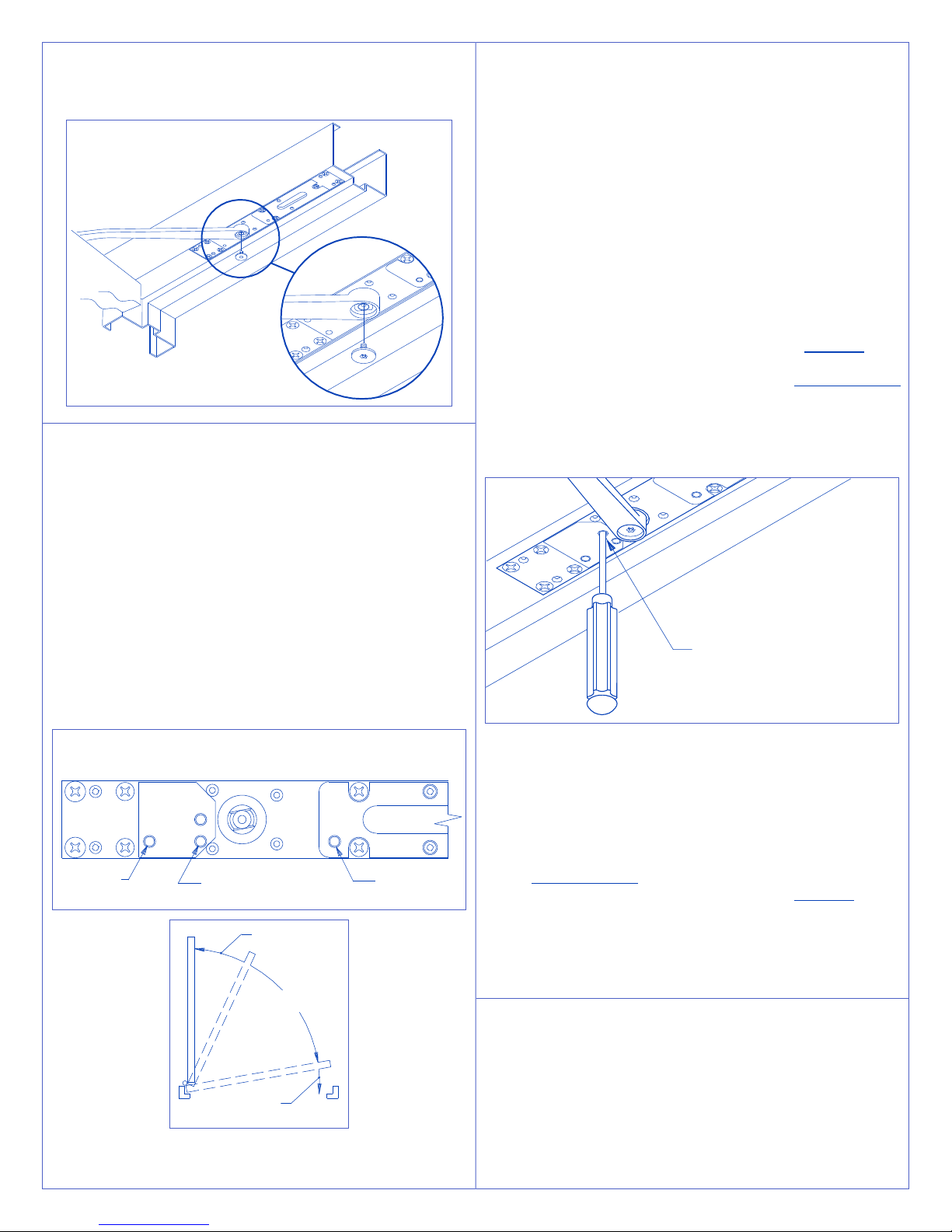

To adjust the signaling point for the door farther from the closed

position:

d. Open the door approximately 20°, or enough to access

the signal adjustment hole in mounting plate (See Fig. 7,

on previous page). Prevent door from moving during the

adjustment. Insert the No. 3 Phillips screwdriver into the

signal adjustment hole to engage the trigger gear.

e. For Right Hand Door: turn the screwdriver

counterclockwise VERY SLIGHTLY

For Left Hand Door: turn the screwdriver clockwise VERY

SLIGHTLY

f. REMOVE SCREWDRIVER BEFORE ALLOWING DOOR

TO MOVE. Allow the door to close completely. Check the

signal activation point. If still too close to the “door closed”

position, repeat steps d, e & f.

1j CLOSING POWER ADJUSTMENT:

Depending on width of door, the 2210DPS has been ordered as

one of three sizes: 2213, 2214 or 2215. Determine closer size

from either label on box or UL label on mounting plate.

Adjustment can be made with a at head screwdriver (see Fig. 8).

Adjustment range for each size is as follows:

• 2213: Closer is shipped at minimum closing power. If

MORE closing power is required, turn adjusting screw

counterclockwise, but not more than 36 full turns. DO NOT turn

adjusting screw clockwise.