GENERAL INFORMATION

The 4600 series installation has three sections:

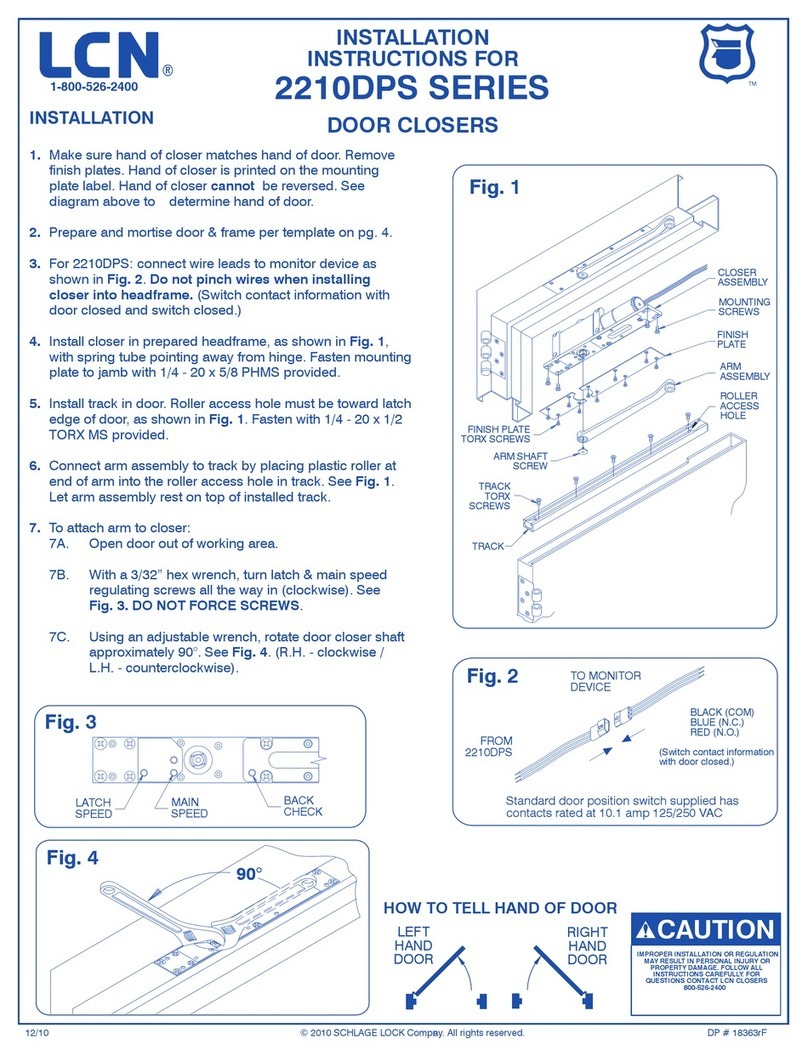

Section 1 - Fastening mounting channel to frame / electrical connections.

Section 2 - Installing closer body & arm assembly

Section 3 - Installation of controller and adjustment of settings.

Follow all instructions carefully. Failure to do so may result in personal injury or property damage. Use

extreme caution when dealing with high voltage. High voltage connections should be made by a qualified

professional. If you have any questions, call LCN at 800 - 526 - 2400.

The 4600 series Auto-Equalizer is designed to meet the following codes & standards:

- ANSI A156.19, section 2.1

- ANSI A117.1, section 4.13.11 requirements.

- ADA law section 4.13.12

- UL listed for use on labeled doors.

- Complies with UL & NEC requirements for Class 1 (high voltage) & Class 2 (low voltage) by

providing separate conduit connections for each.

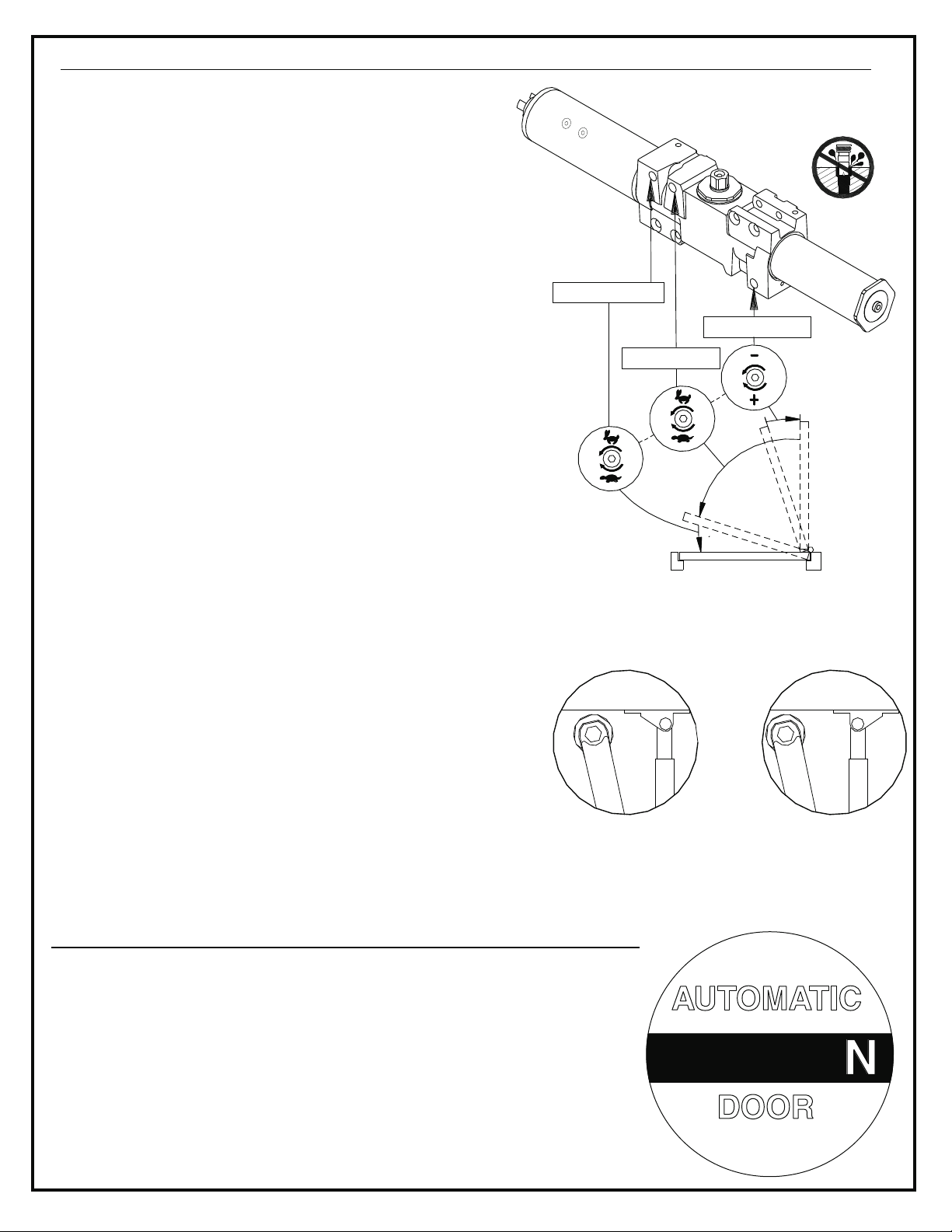

Both the 4631 & 4642 are non-handed, non-sized door operators that provide all the standard features

of a heavy duty LCN door closer; including independent adjustment of backcheck, main speed and latch

speed functions as well as adjustable closing power: 4631 (size 1 to 4) / 4642 (size 2 to 5). Both models

are shipped with LCN's "Ultra X" all-weather hydraulic fluid for reliable operation at a wide range of

temperatures. Requirements for installation are as follows:

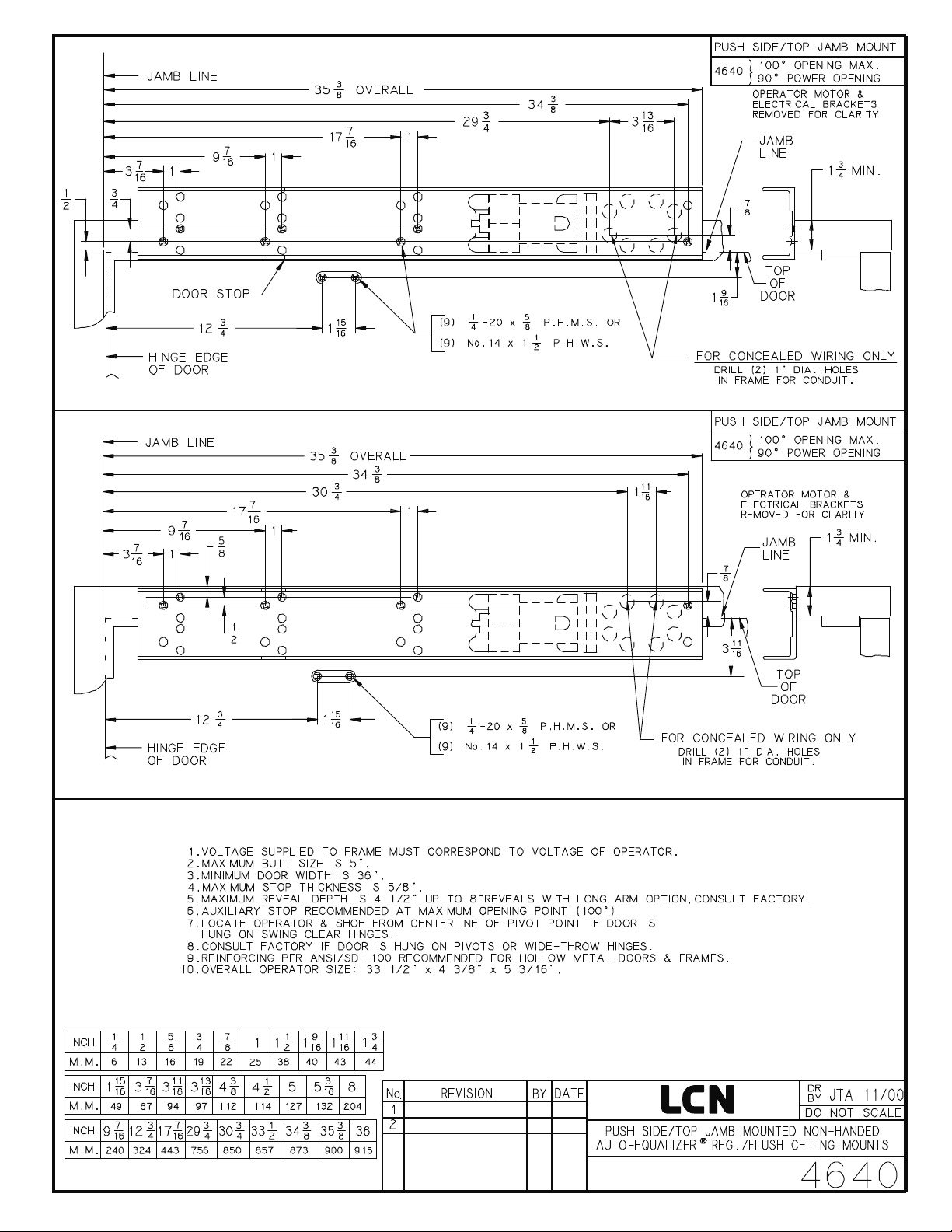

- The 4631 is designed for pull side installation on the top jamb and requires a minimum door width of

36" and a 2" min. head frame. Top rail of door must be 1 " min. and butt hinge size should not

exceed 5". Maximum pull side reveal of ".

- The 4642 is designed for push side installation on the top jamb for both standard and flush ceiling

conditions. It requires a minimum door width of 36" and a 1 " min. head frame. Top rail of door

must be at least 1 " and butt hinge size should not exceed 5". The 4642 accomodates reveals up

to 4 ". For reveal depths of 4 " - 8", requires 4642 L (Long Arm). For reveal depths greater

than 8" - consult factory.

The 4600 series can accommodate both surface and concealed wiring

applications. Maximum AC current load is 1.5 amps.

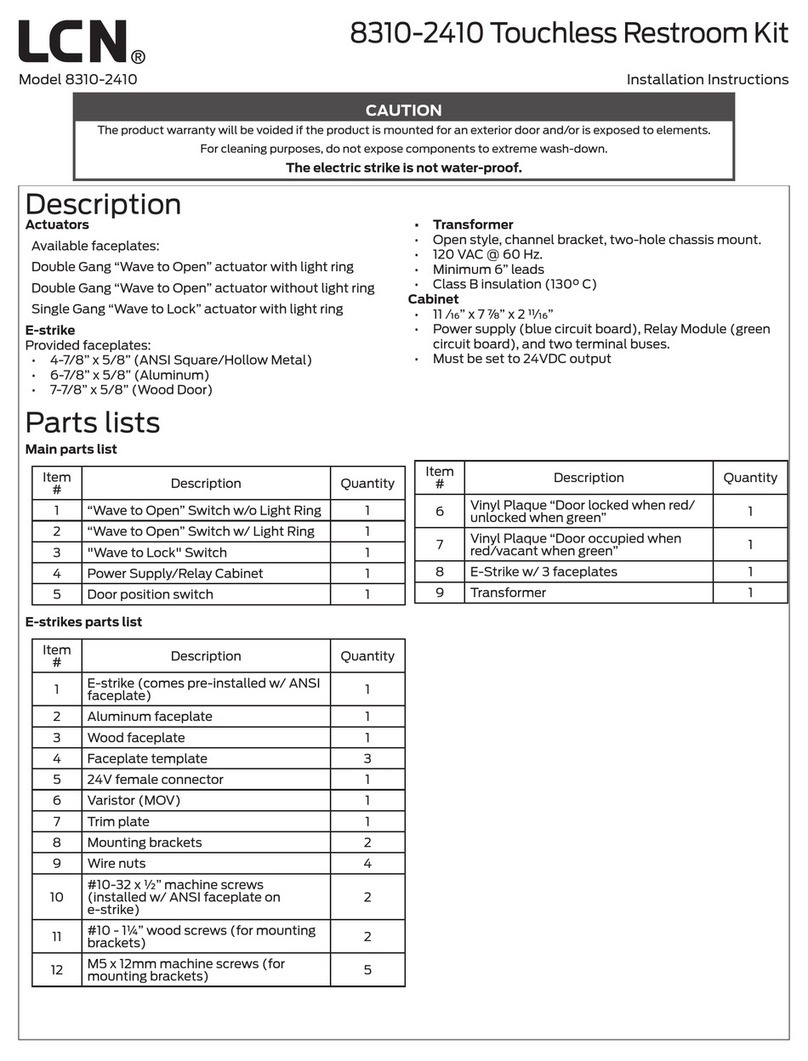

A built-in 12VDC & 24VDC power supply (rated for 1 amp combined current load) can power

peripheral actuators, electronic strikes or mag-lock devices. The 4600 series is compatible with all

LCN 7900 series actuators and scanners. High-security card readers or keypads may also be used as

actuators. The 4600 series will accept inputs from a wide variety of security systems, allowing security

personnel to regulate accessability. A 4600 will accept a fire alarm input to deactivate unit when fire

alarm is triggered. A circuit breaker and resettable fuses protect high-voltage inputs and low-voltage

output circuits, respectively. To ensure proper electrical functions, installation should be made when

temperature is between 35° F up to 120° F .

1/8

3/4

3/4

1/2 1/2

1/8

ELECTRICAL INFORMATION:

It requires 120VAC supplied to the operator.

®

This installation instruction sheet is a valuable reference and should not be discarded. It

should be given to building owner or maintenance supervisor after installation is complete.

Page 2