Table of contents

Leuze electronic GmbH + Co. KG BCL 208i 3

Table of contents

1 About this document ............................................................................................5

2 Safety .....................................................................................................................7

2.1 Intended use ...........................................................................................................................7

2.2 Foreseeable misuse ............................................................................................................... 7

2.3 Competent persons ................................................................................................................ 8

2.4 Disclaimer ............................................................................................................................... 8

2.5 Laser safety notices................................................................................................................8

3 Fast commissioning .............................................................................................9

3.1 Mounting ................................................................................................................................. 9

3.2 Selecting a mounting location.................................................................................................9

3.3 Electrical connection...............................................................................................................9

3.4 Preparatory settings..............................................................................................................10

3.4.1 Manually setting the IP address ........................................................................................10

3.4.2 Automatically setting the IP address .................................................................................11

3.4.3 Ethernet host communication............................................................................................11

3.5 Further settings.....................................................................................................................12

3.6 Starting the device ................................................................................................................12

3.7 Bar code reading .................................................................................................................. 13

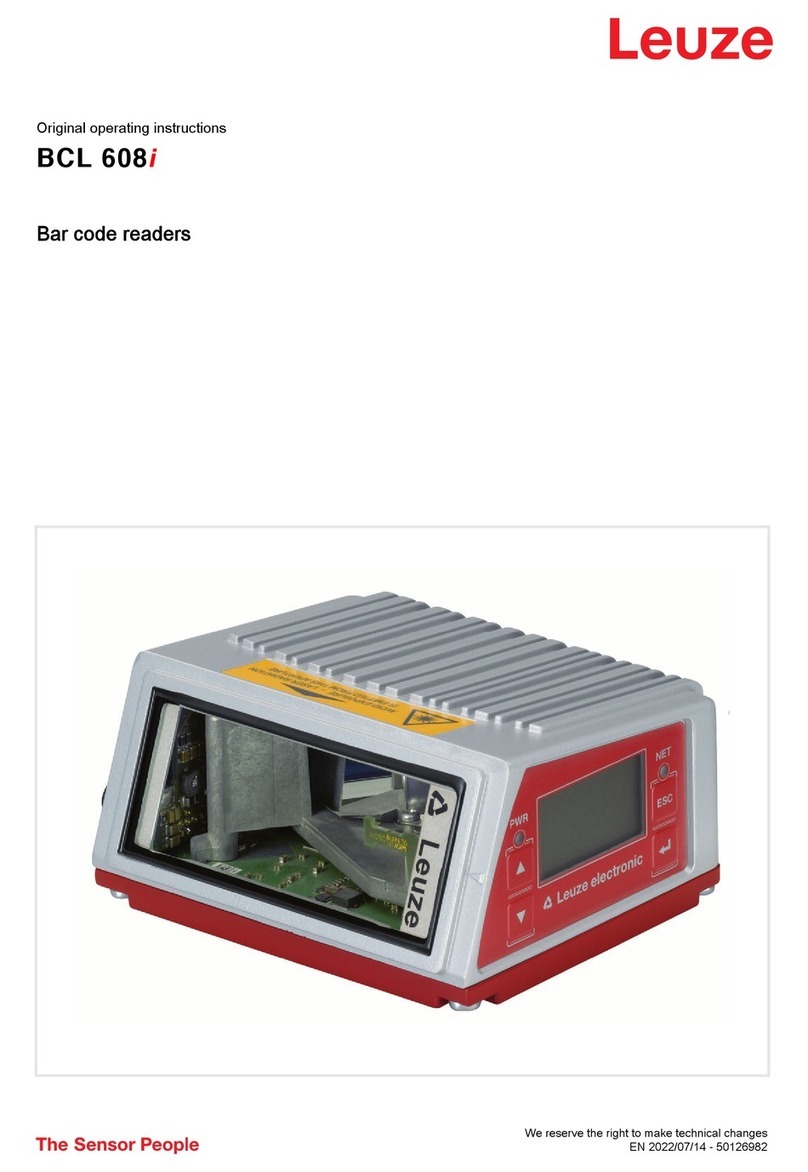

4 Device description ..............................................................................................14

4.1 Device overview....................................................................................................................14

4.2 Performance characteristics .................................................................................................14

4.3 Device construction .............................................................................................................. 16

4.4 Display elements .................................................................................................................. 16

4.5 Reading techniques ..............................................................................................................18

4.5.1 Line scanner (single line) ..................................................................................................18

4.5.2 Raster scanner (raster line)...............................................................................................19

4.6 Fieldbus systems ..................................................................................................................19

4.6.1 Ethernet.............................................................................................................................19

4.6.2 Ethernet – star topology ....................................................................................................20

4.7 autoReflAct ........................................................................................................................... 20

4.8 Reference codes...................................................................................................................21

4.9 autoConfig ............................................................................................................................ 21

5 Mounting..............................................................................................................22

5.1 Transport and storage .......................................................................................................... 22

5.2 Mounting ...............................................................................................................................22

5.2.1 Mounting with M4 fastening screws ..................................................................................22

5.2.2 Mounting with BT56 or BT56-1 mounting device ............................................................22

5.2.3 Mounting with BT300-1 mounting device .........................................................................23

5.2.4 Mounting with the BT300W mounting bracket.................................................................23

5.3 Selecting a mounting location...............................................................................................23

5.4 Cleaning................................................................................................................................ 25

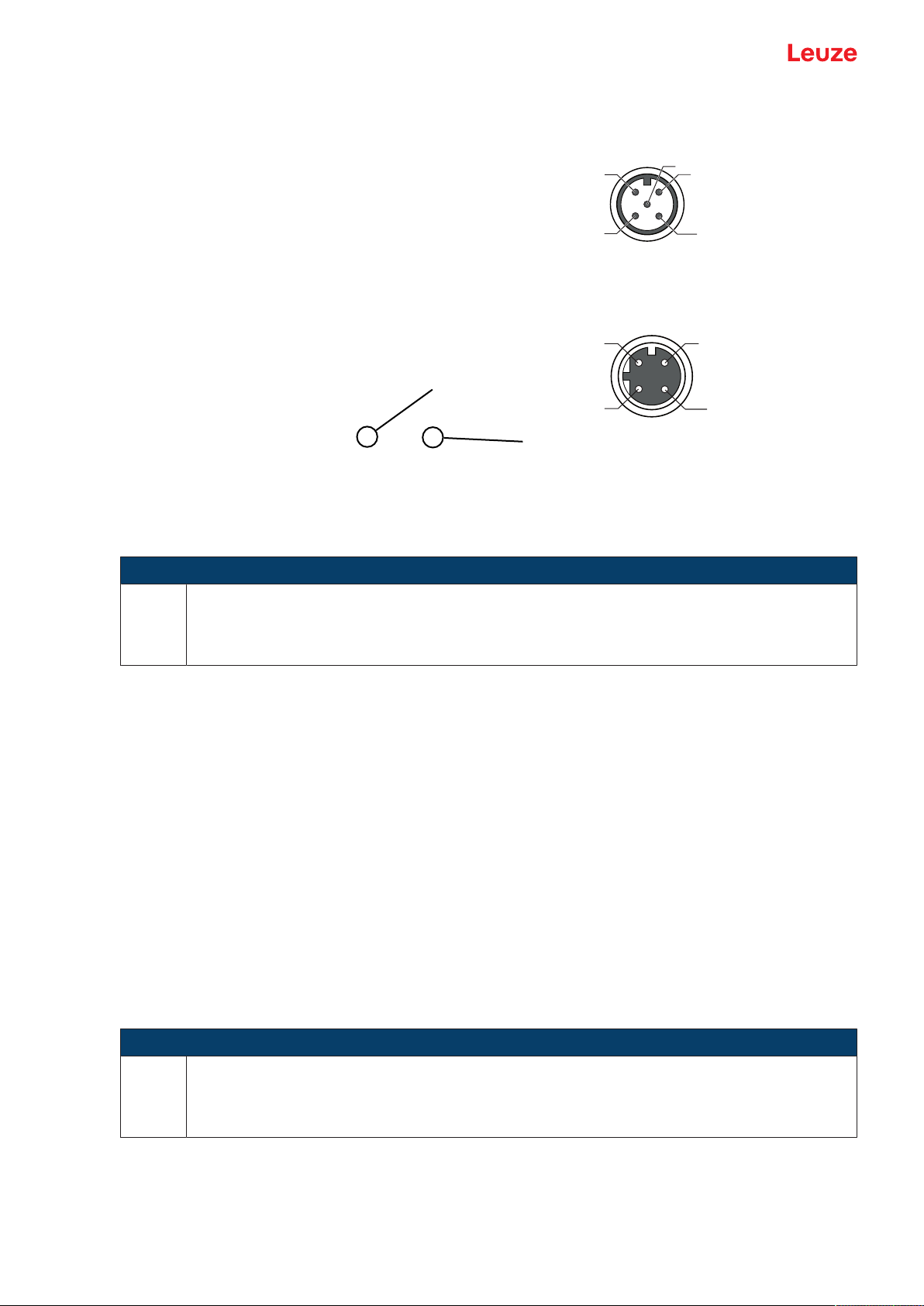

6 Electrical connection..........................................................................................26

6.1 PWR/SWIO (supply voltage, switching input and switching output) ..................................... 27

6.2 HOST (Ethernet, cable assignments) ................................................................................... 29

6.3 Ethernet topologies...............................................................................................................31

6.4 Cable lengths and shielding.................................................................................................. 31