3

CONTENTS

1. APPLICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. TRANSDUCER SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. BASIC REQUIREMENTS, OPERATIONAL SAFETY. . . . . . . . . . . . . . . . 5

4. INSTALLATION .......................................................................... 6

4.1. Assembly ............................................................................................6

4.2. Electrical Connections ........................................................................7

5. SERVICING ................................................................................ 9

5.1. Messages after supply switching on ...................................................9

5.2. Description of P18D display ..............................................................10

5.3. Function of capacitive button ............................................................ 11

5.4. Function of the P18D transducer ...................................................... 11

5.4.1. Measured and calucated values ............................................. 12

5.4.2. Chosen of values for analog outputs.......................................13

5.4.3. Individual characteristic of analog outputs ..............................13

5.4.4. Default parameters..................................................................15

6. RS-485 interface...................................................................... 16

6.1. Serial interface connection................................................................16

6.2. Description of the Modbus Protocol Implementation.........................17

6.3. Description of the Modbus functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.4. Register map.....................................................................................20

6.5. Register for write or readout..............................................................21

6.6. Register only for readout...................................................................24

6.7. Emergency restoration of default parameters ...................................26

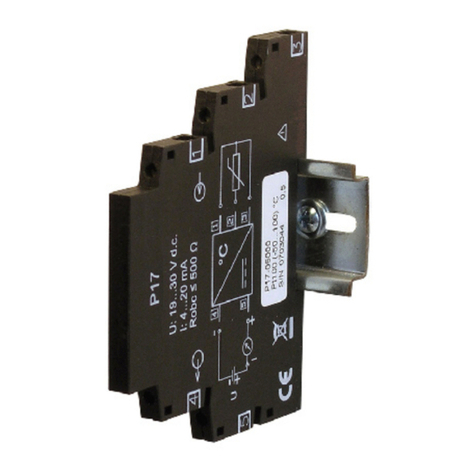

7. ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8. TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9. ORDERING CODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

10. MAINTENANCE AND GUARANTEE ....................................... 31