ULT20 - User’s manual_rev.A 2

Contents

1 Application.......................................................................................................................................3

2 Transducer set...................................................................................................................................4

3 Basic requirements, operational safety ............................................................................................5

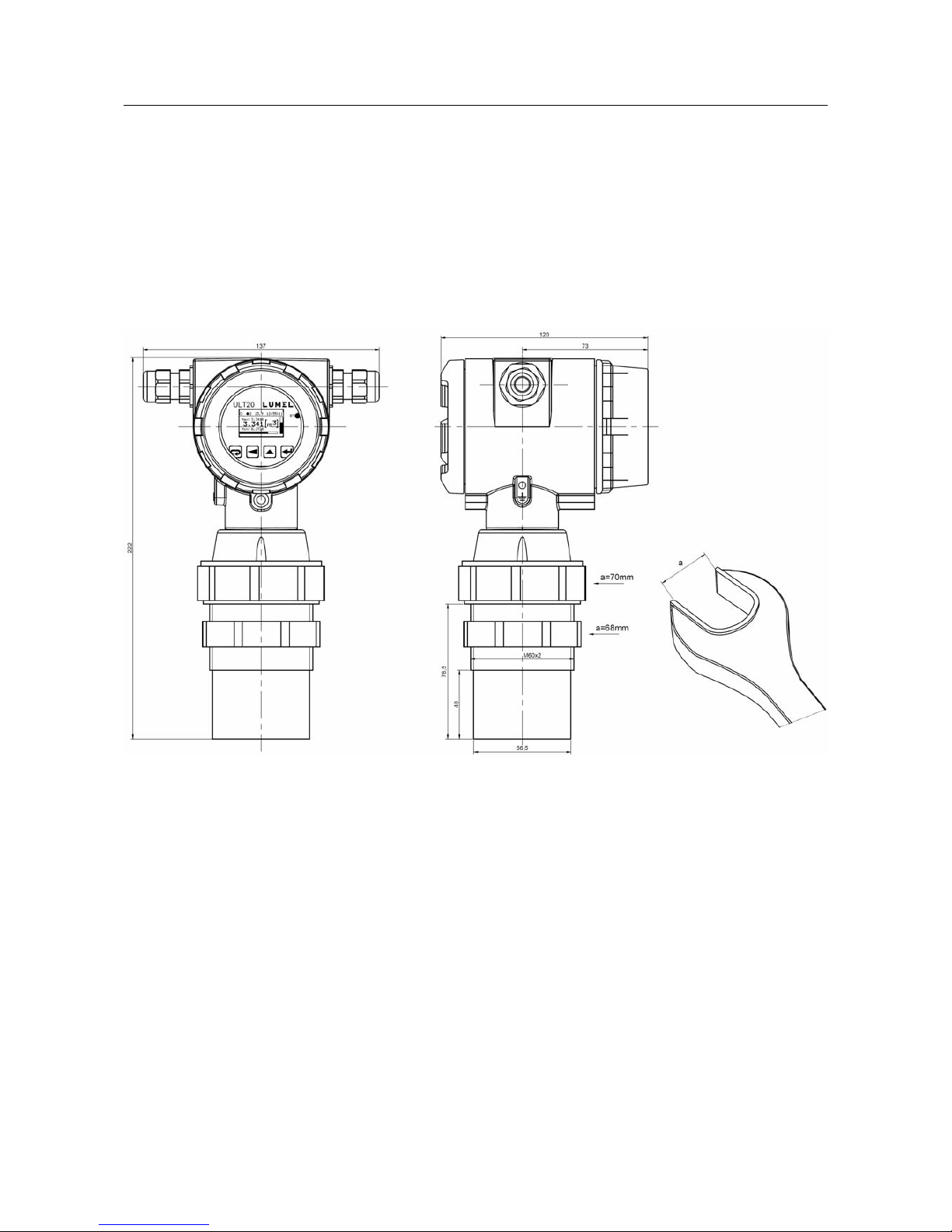

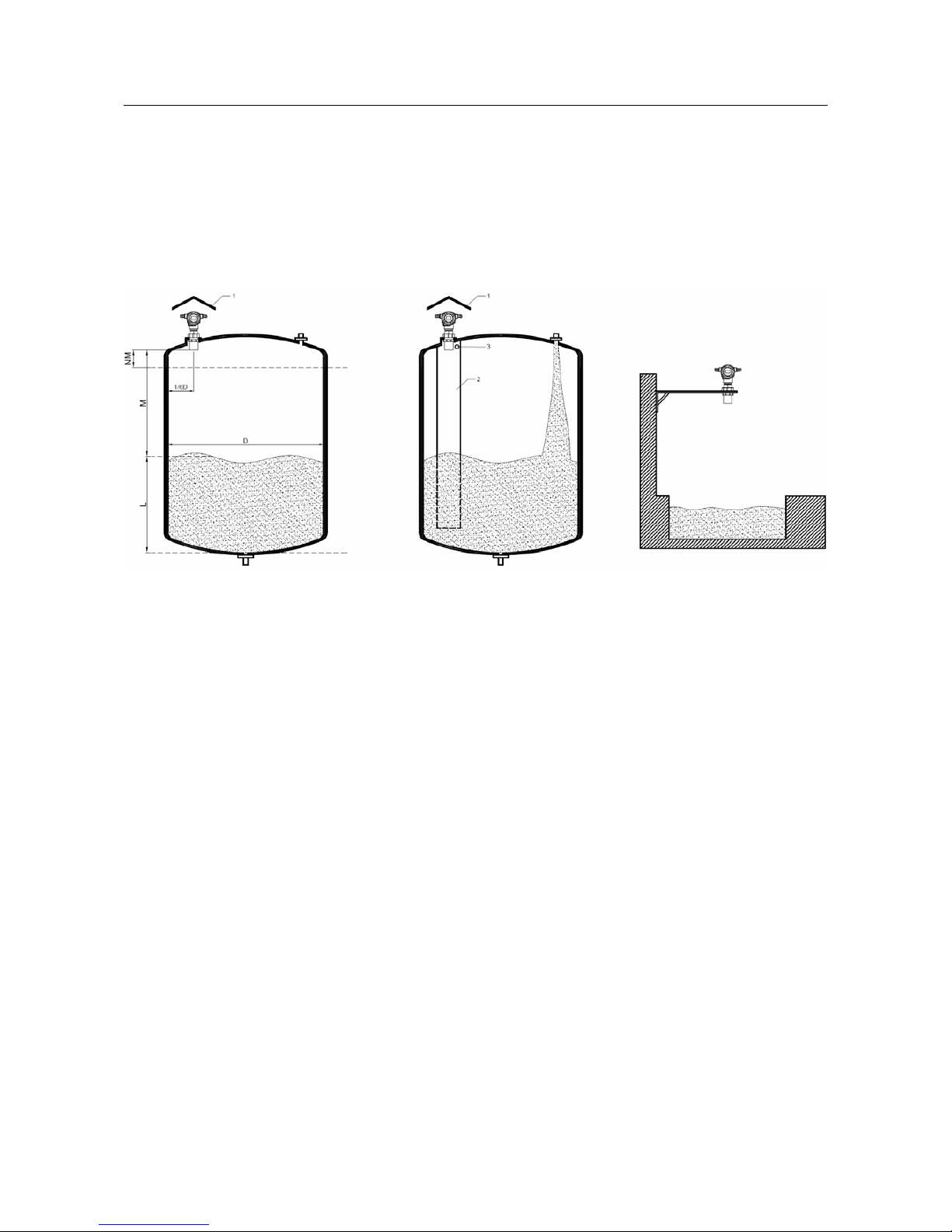

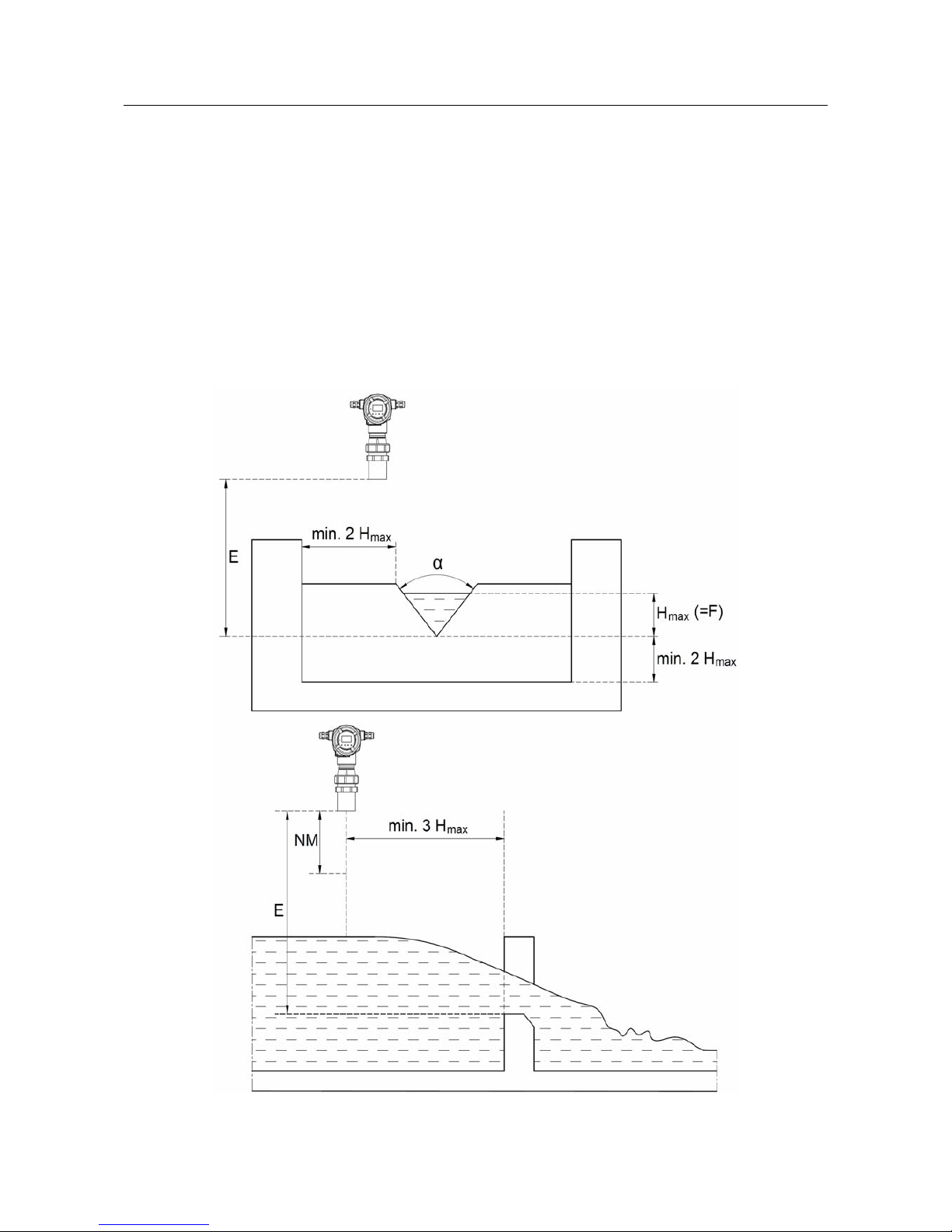

4 Installation .......................................................................................................................................6

4.1 Method of installation ..............................................................................................................6

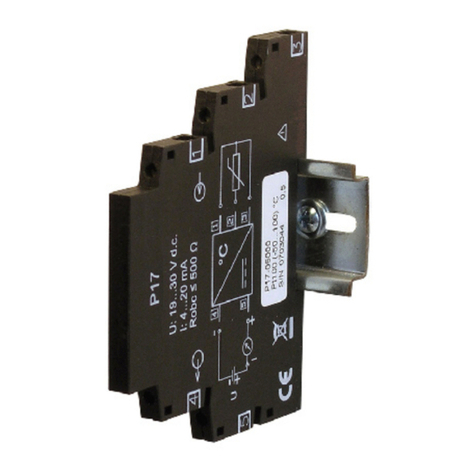

4.2 External connections diagram ..................................................................................................7

4.3 Examples of applications..........................................................................................................9

5 Operation .......................................................................................................................................11

5.1 Description of front panel ......................................................................................................11

5.2 Functions of buttons ...............................................................................................................12

5.3 Transducer parameters programming ....................................................................................14

5.3.1 Changing value of selected parameter ...........................................................................16

5.3.2 Programmable transducer parameters ............................................................................17

5.4 Functions of the transducer ....................................................................................................23

5.4.1 Distance measurement ...................................................................................................23

5.4.1.1 Measured value averaging ......................................................................................24

5.4.1.2 Minimum and maximum measured values ............................................................24

5.4.1.3 Individual characteristics ........................................................................................25

5.4.1.4 Counter....................................................................................................................26

5.4.2 Analog output .................................................................................................................26

5.4.3 Binarny pulse output ......................................................................................................27

5.4.4 Alarm outputs .................................................................................................................28

5.4.5 LCD display ..................................................................................................................29

5.5 Factory settings.......................................................................................................................31

5.6 Archiving ...............................................................................................................................33

5.6.1 Structure of record .........................................................................................................34

5.6.2 Measured values archiving .............................................................................................35

5.6.3 Events archiving .............................................................................................................36

5.6.4 Downloading archived data ............................................................................................38

5.7 RS-485 interface ....................................................................................................................39

5.7.1 Connection .....................................................................................................................40

5.7.2 Description of MODBUS protocol implementation. .....................................................41

5.7.3 Implemented functions of MODBUS protocol ..............................................................41

5.7.4 Map of registers .............................................................................................................41

5.7.4.1 Registers 4000 – 4081.............................................................................................42

5.7.4.2 Registers 4300 – 4435............................................................................................48

5.7.4.3 Registers 5000 – 5272............................................................................................53

5.7.4.4 Registers 7500 – 7533 and 8000 – 8065 ................................................................53

5.7.4.5 Registers 7800 – 7949 and 8200 – 8498.................................................................55

5.8 USB interface .........................................................................................................................59

6 Error codes .....................................................................................................................................60

7 Technical data ................................................................................................................................61

8 Ordering code ................................................................................................................................63