5. OPERATION

After the transducer is switched on, its Status LED

should illuminate in red (transducer initialization), then it should

turn green (normal operation).

Status LED of the transducer:

when illuminated in green – normal

operation;

when illuminated in red – incorrect

operational parameters; re-configure

the transducer;

when flashes in red – no calibration

or damaged non-volatile memory;

transduce should be returned to the

manufacturer;

LEDs installed only in version with RS485

interface:

RxD LED is on – data receipt;

TxD LED is on – data transmission.

•

•

•

•

•

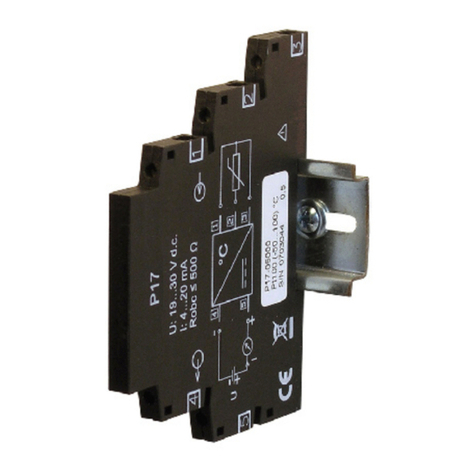

Fig. 4. P21Z transducer view.

Data entry into the register is confirmed by a short illu-

mination of the Status LED in red.

Before the required number of correct measurements

(according to Table 1) is achieved, the device displays arithme-

tic mean from the completed measurements. Subsequent me-

asurements are added applying the walking window principle,

i.e. the “oldest” measurement is deleted and replaced

by the most recent one. When values outside the measuring ran-

ge are measured, the device indicates it and correct measure-

ments are counted from the beginning. Default time is set to 1s.