48NDVA

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-9441-A Rev.9 P. 8 / 9

■BARGRAPH / DIGITAL INDICATOR ZERO ADJUSTMENT

1) Apply 0% input signal.

2) Hold down [M] for 3 seconds*1and push [M] to choose [Z].

3) Press [UP] and [DOWN] buttons at once. (Blinking Z

LED is switched to continuous ON state.)

4) Press [UP] or [DOWN] buttons until the bargraph shows

0%, and the digital indicator comes to a desired value,

and press [SET].

■DIGITAL INDICATOR ZERO ADJUSTMENT

1) Hold down [M] for 3 seconds*1and push [M] to choose [Z].

2) Press [UP] or [DOWN] buttons until the digital indicator

comes to a desired value, and press [SET].

■BARGRAPH / DIGITAL INDICATOR SPAN ADJUSTMENT

1) Apply 100% input signal.

2) Hold down [M] for 3 seconds*1and push [M] to choose [S].

3) Press [UP] and [DOWN] buttons at once. (Blinking S

LED is switched to continuous ON state.)

4) Press [UP] or [DOWN] buttons until the bargraph shows

100%, and the digital indicator comes to a desired value,

and press [SET].

■DIGITAL INDICATOR SPAN ADJUSTMENT

1) Hold down [M] for 3 seconds*1and push [M] to choose [S].

2) Press [UP] or [DOWN] buttons until the digital indicator

comes to a desired value, and press [SET].

■DECIMAL POINT POSITION

1) Hold down [M] for 3 seconds*1and push [M] to choose [P].

2) Press [UP] or [DOWN] buttons until the decimal point

comes to a desired position, and press [SET].

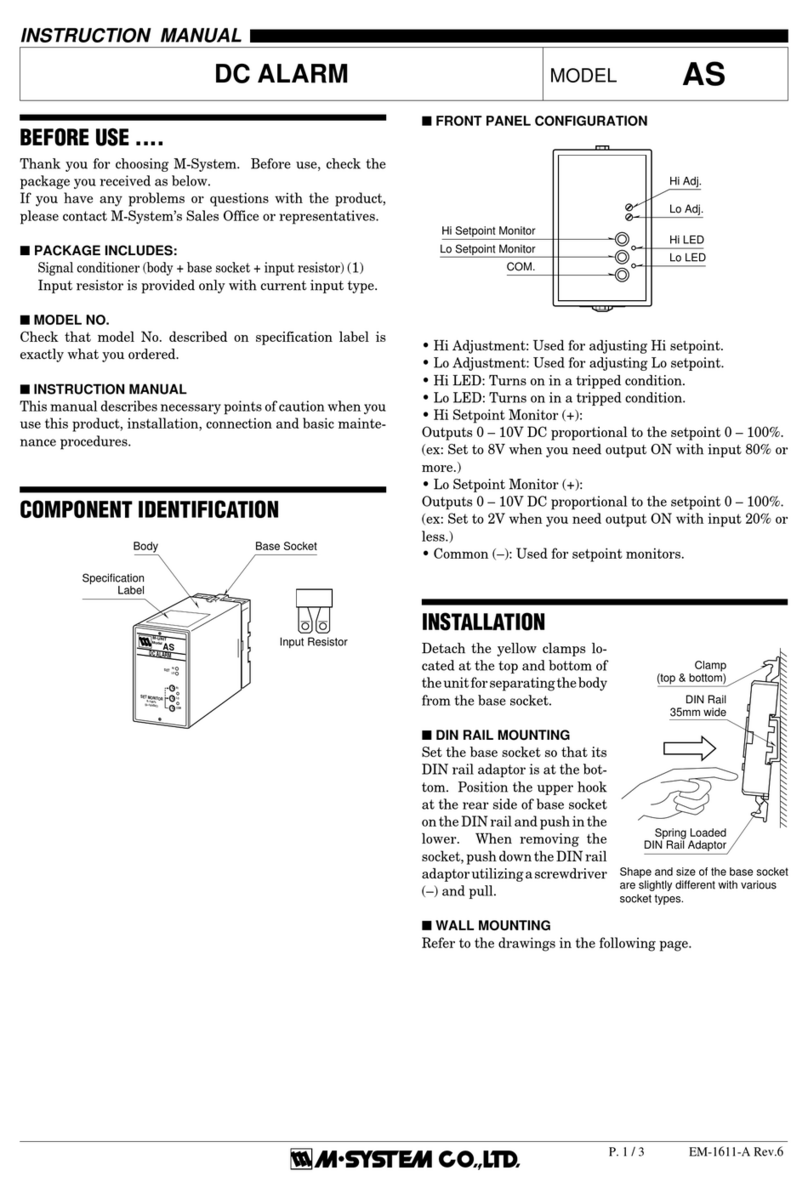

■ALARM SETPOINT ADJUSTMENTS

• 48NDVA-2: H [L setpoint] to 100%

L 0% to [H setpoint]

No alarm trip is selectable

• 48NDVA-4: HH [H setpoint] to 100%

H [L setpoint] to [HH setpoint]

L [LL setpoint] to [H setpoint]

LL 0% to [L setpoint]

No alarm trip is selectable

• How to Set LL (or L, H, HH, 1, 2) Setpoints

1) Hold down [M] for 3 seconds*1and push [M] to choose

[LL].

2) Press [UP] or [DOWN] buttons until the digital indicator

comes to the desired value, and press [SET].

(Same procedure for L, H, HH, 1, 2 setpoints)

• How to Cancel HH and H Alarms

1) Press [UP] or [DOWN] buttons until the indicator comes

to the upper limit (digital indicator shows “----”), and

press [SET].

HH indicator must be set before H as the H setpoint can-

not go above the HH setpoint.

• How to Cancel LL and L Alarms

1) Press [UP] or [DOWN] buttons until the indicator comes

to the lower limit (digital indicator shows “----”), and

press [SET].

LL indicator must be set before L as the L setpoint can-

not go below the LL setpoint.

■LL (or L, H, HH, 1, 2) ALARM ON TIME DELAY

1) Hold down [M] for 3 seconds*1and push [M] to choose

[LL].

2) Press [UP] and [DOWN] buttons at once. Current setting

value in seconds is shown at the right end of the digital

indicator, with ‘d.’ at the left end.

Factory default setting is “0”.

3) Press [UP] or [DOWN] buttons until the meter shows the

desired value, and press [SET]. (The range between 0 to

15 sec. can be set.)

(Same procedure for L, H, HH, 1, 2 setpoints)

■MOVING AVERAGE SAMPLE NUMBER

1) Hold down [M] for 3 seconds*1and push [M] to choose [P].

2) Press [UP] and [DOWN] buttons at once. Current setting

value is shown at the right end of the digital indicator,

with ‘A.’ at the left end.

Factory default setting is “4”.

3) Press [UP] or [DOWN] buttons until the indicator shows

the desired value (1, 2, 4, 8 or 16), and press [SET].

■LED BRIGHTNESS ADJUSTMENT

1) Hold down [M] for 3 seconds*1and push [M] to choose [P].

2) Press [UP] and [DOWN] buttons at once for two times.

Current setting value is shown on the digital indicator,

with ‘c.’ at the left end. Factory default setting is ‘7,’ the

brightest.

3) Press [UP] or [DOWN] buttons until the indicator shows

the desired setting (1 through 7), and press [SET].

■DC OUTPUT FINE ZERO ADJUSTMENT (0%)

1) Apply 0% input signal.

2) Hold down [M] for 3 seconds*1and push [M] to choose [Z].

3) Press [UP] and [DOWN] buttons at once for two times

until the Z indicator changes from blinking to solid to

blinking in double speed. Digital indicator shows “_ _ _ _”

and it blinks.

4) Press [UP] or [DOWN] buttons to show a desired value at

the receiving instrument, and press [SET].

■DC OUTPUT FINE SPAN ADJUSTMENT (100%)

1) Apply 100% input signal.

2) Hold down [M] for 3 seconds*1and push [M] to choose [S].

3) Press [UP] and [DOWN] buttons at once for two times

until the S indicator changes from blinking to solid to

blinking in double speed. Digital indicator shows “_ _ _ _”

and it blinks.

4) Press [UP] or [DOWN] buttons to show a desired value at

the receiving instrument, and press [SET].