CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

7 – 8 with a multimeter.

3) Input: Check voltage across the terminal 5 (+) – 6 (–)

with a multimeter.

4) Excitation: Check voltage (5V ±2%) across the terminal

4 (+) – 6 (–) with a multimeter.

5) Relay operation: Check that the relays operates accord-

ing to input signals as shown in the figure below.

6) Output load: Check that the output load is 380V

AC/120VA or 125V DC/30W at the maximum. For use

with inductive load, external protection is recommended.

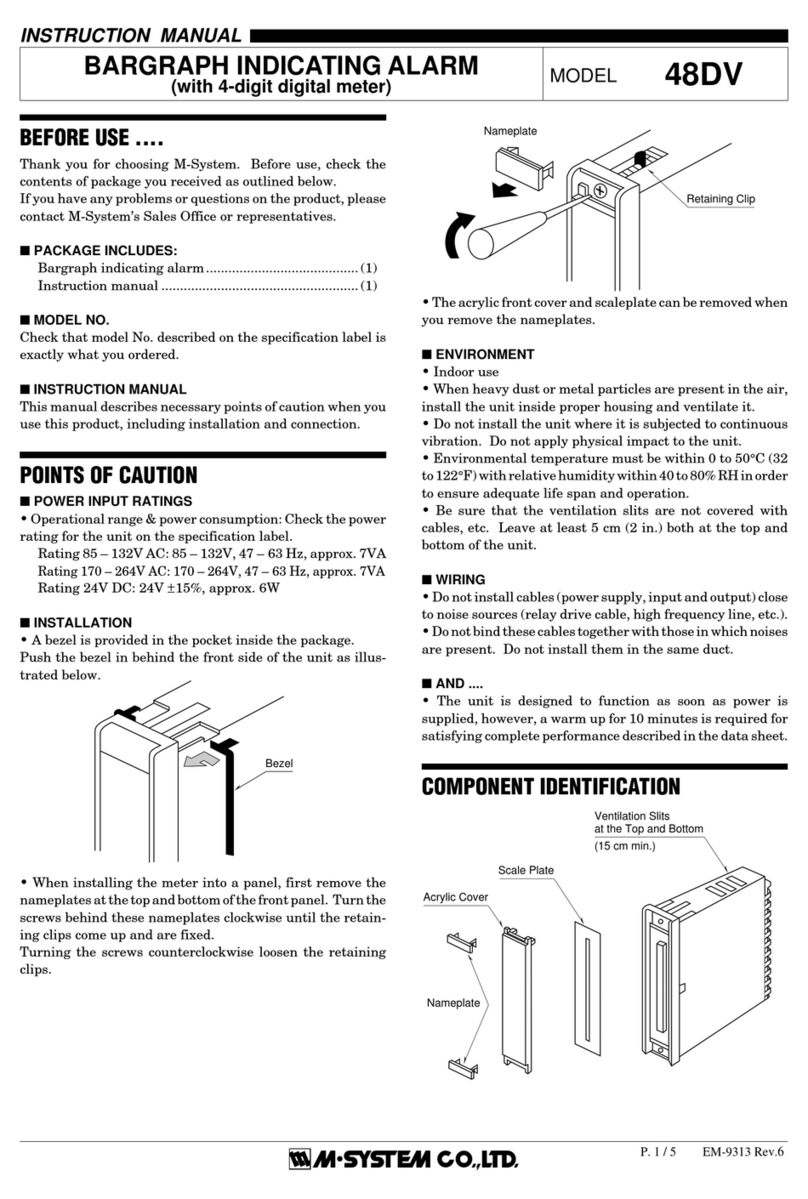

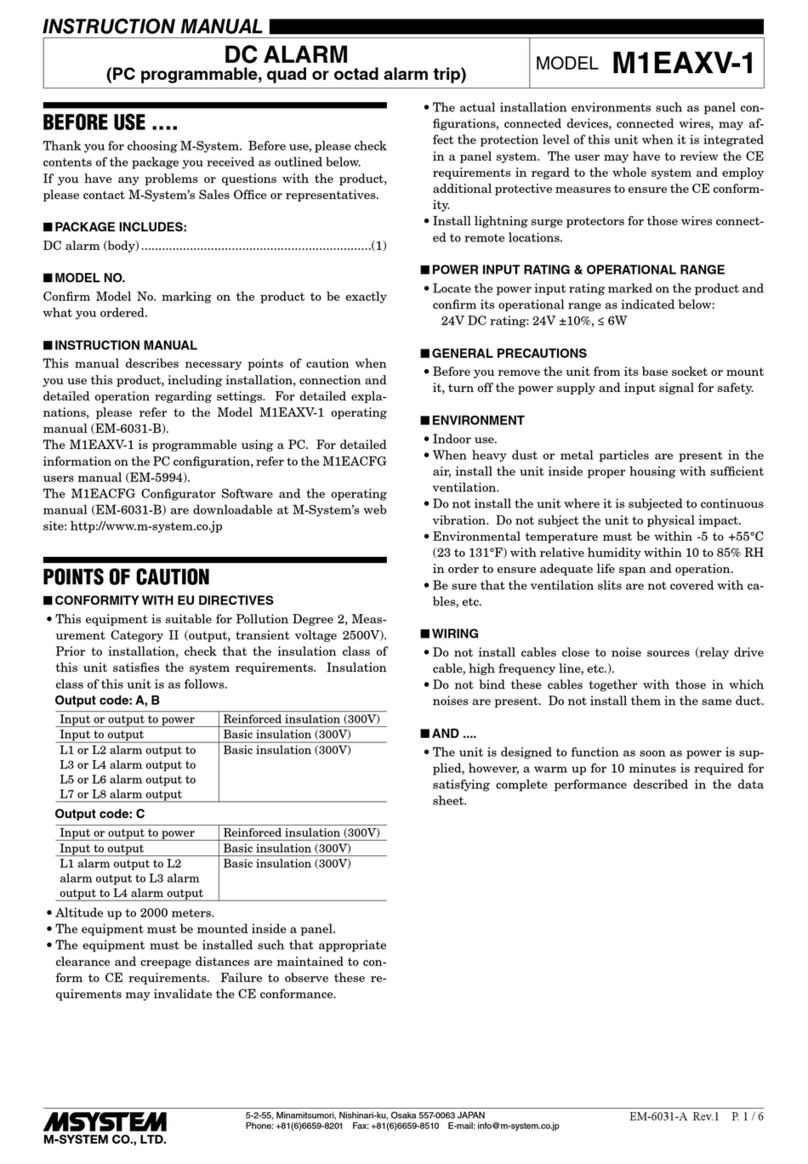

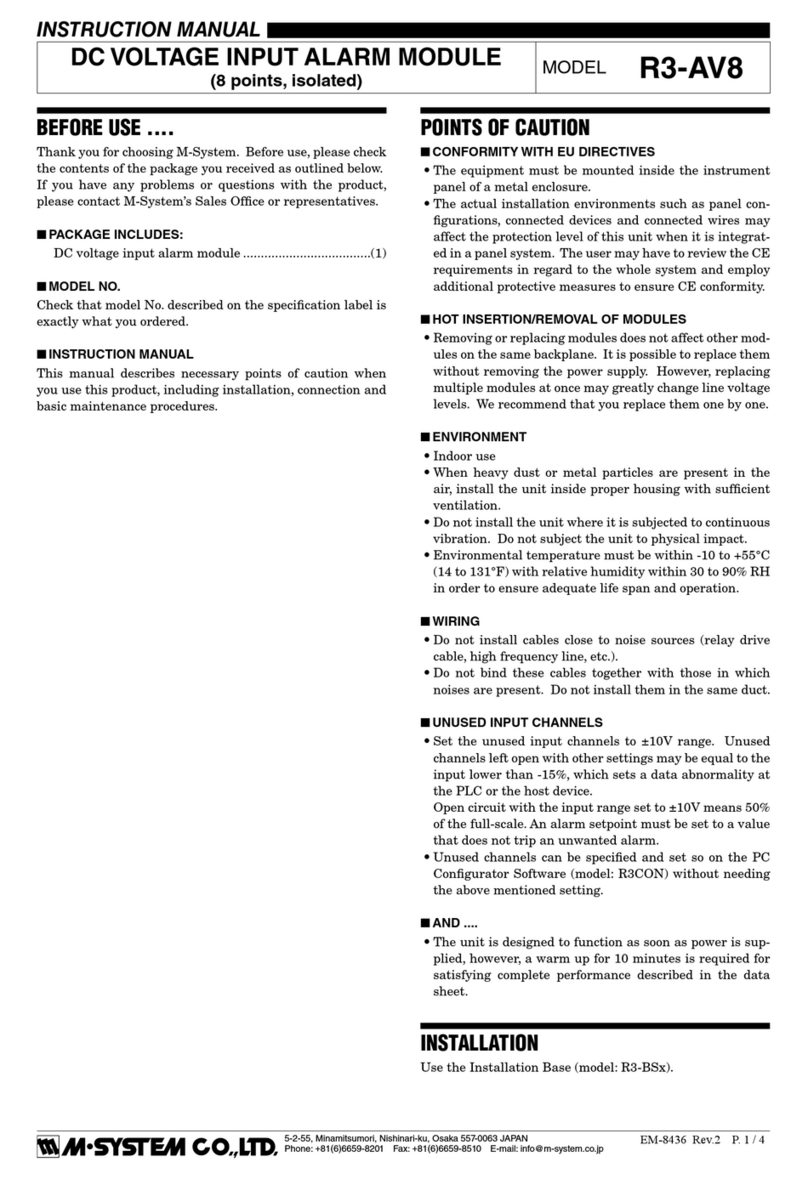

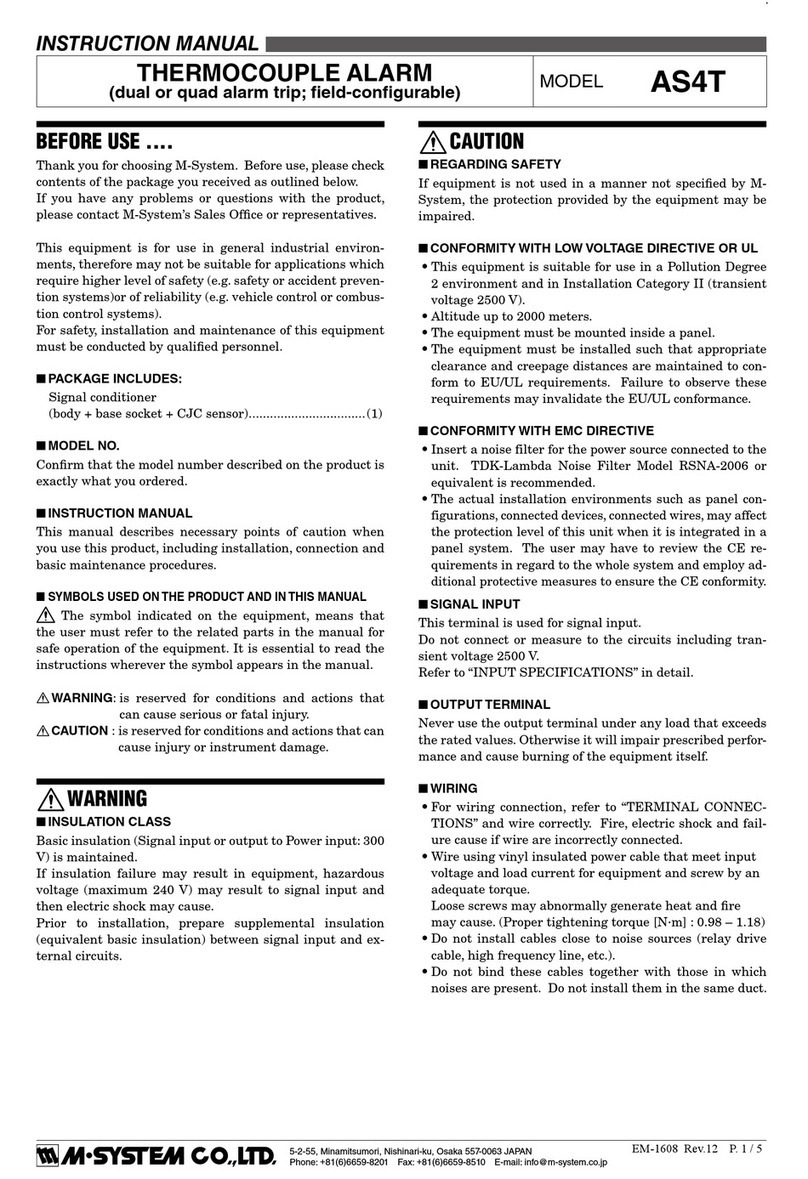

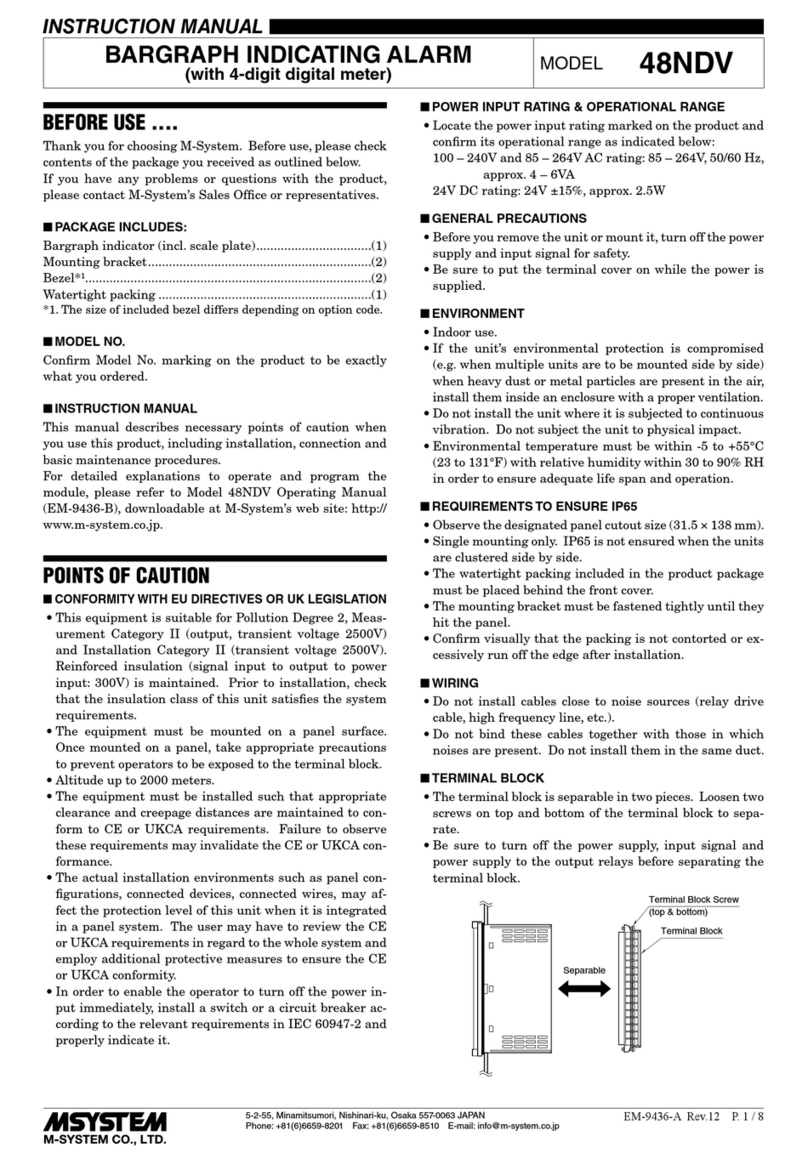

ALARM TRIP OPERATION

Alarm Trip Operation Terminal No. in parentheses

Trip Operation in Power Failure

•Output Code: 1 & 4

•Output Code: 2 & 3

050 100▲

Input

(%)

Output 2

Setpoint

▲

Output 1

Setpoint

Output 1 (9-10)ON

Output 2 (1-2)ON

(1-3)ON

(9-11)ON

CALIBRATION

This unit is calibrated at the factory with reference input.

Thus, the unit must be calibrated in combination with the

angle sensor that is actually used.

Use a signal source and measuring instruments of sufficient

accuracy level.

■HOW TO CALIBRATE THE INPUT MONITOR

Connect the unit to the angle sensor and turn the power

supply on, and wait for at least 10 minutes until the unit

warms up before starting calibration.

Adjust output voltage across the input monitor terminal (+)

and the terminal 6 (–).

1) ZERO: Adjust the input angle to 0% and adjust output to

0 V. * 1

2) SPAN: Adjust the input angle to 100% and adjust output

to 4V. *1

3) Check ZERO output again with applying 0% input.

4) When ZERO value is changed, repeat the above proce-

dure 1) – 3).

*1. When alarm setpoints cannot be set close to 0% or 100%,

adjust output voltage so as to be slightly higher than 0V

(approx. 0.005V) for ZERO or slightly lower than 4V (ap-

prox. 3.995V) for SPAN.

ADJUSTMENT PROCEDURE

■ALARM SETPOINT AND DEADBAND (HYSTERESIS)

1) Apply a simulated input signal corresponding to the

alarm setpoint.

2) For a Hi (Lo) setpoint, turn the setpoint adj. from 100%

(0%) until the relay trips.

3) Decrease (increase) the input signal by desired deadband

width.

4) Turn the deadband adj. from 100% (0%) until the relay is

released.

MAINTENANCE

Perform calibration according to the procedures below for

regular maintenance:

■CALIBRATION OF INPUT MONITOR

1) Warm up the unit for at least 10 minutes.

2) Apply 0%, 25%, 50%, 75% and 100% input angles.

3) Confirm that voltage across the input monitor terminal

(+) and the terminal 6 (–) becomes 0, 1, 2, 3, and 4V cor-

responding to the respective input angles.

4) When the voltage is deviated, recalibrate the unit accord-

ing to the procedure of “CALIBRATION” explained ear-

lier.

■CALIBRATION OF ALARM OUTPUT

Warm up the unit for at least 10 minutes.

• Hi Setpoint

Increase the input signal from a value lower than the set-

point and check that the trip point remains within the

accuracy described in the data sheet.

• Lo Setpoint

Decrease the input signal from a value higher than the

setpoint and check that the trip point remains within the

accuracy described in the data sheet.

When the trip points are shifted, please contact M-System’s

Sales Office or representatives.

LIGHTNING SURGE PROTECTION

M-System offers a series of lightning surge protector for

protection against induced lightning surges. Please contact

M-System to choose appropriate models.

ANR

5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN

Phone: +81(6)6659-8201 Fax: +81(6)6659-8510 E-mail: info@m-system.co.jp

EM-2116 P. 3 / 3