Whirlpool System Care and Cleaning

WARNING!

NEVER USE ABRASIVE MATERIALS,

NOR ABRASIVE CLEANERS ON

THE WHIRLPOOL TRIM. (JETS, AIR

CONTROLS AND SUCTION COVERS)

Only use MILD liquid detergent on trim!

Incorrect cleaning materials can

damage finish on trim, drain/overflow

and supply valves.

READ AND FOLLOW ALL PACk AGE

LABELS AND INSTRUCTIONS!

Step 1:

Step 2:

Step 3:

Whirlpool System Trouble Shooting

Whirlpool did not start?

Pump «Hums», but no water action?

HAND TIGHTEN UNIONS

ONLY!)

Restricted flow from foot or side jet(s)?

Water has excessive foaming?

WARNING!

any Servi Cin G not mentioned

aBove Should Be per Formed

By a quali Fied Servi Ce

repre Sentative.

Whirlpool System Operation

WARNING!

AVOID OPERATING THE WHIRLPOOL

SYSTEM WITHOUT ADEQUATE WATER

IN THE TUB

Step 1:

Step 2:

Step 3:

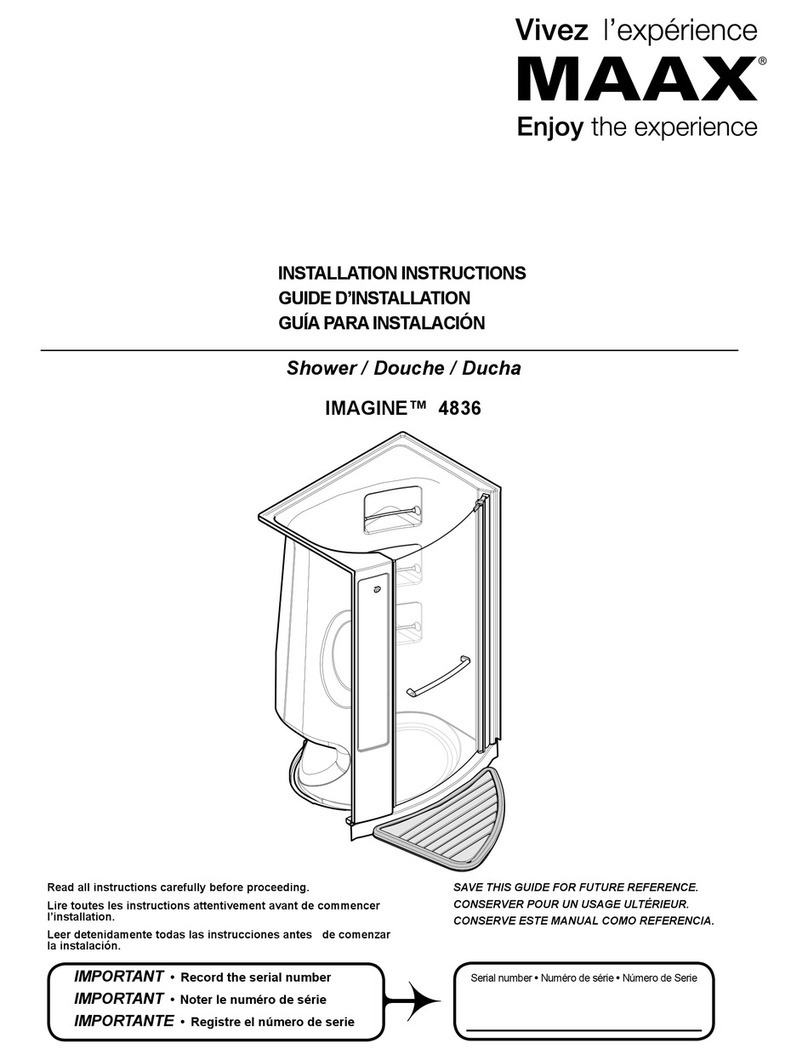

Figure 4 - Minimum Water Level

Water level must be to top of

trim ring on highest jet

before starting the whirlpool

Jet

Nozzle

Jet Trim

Ring

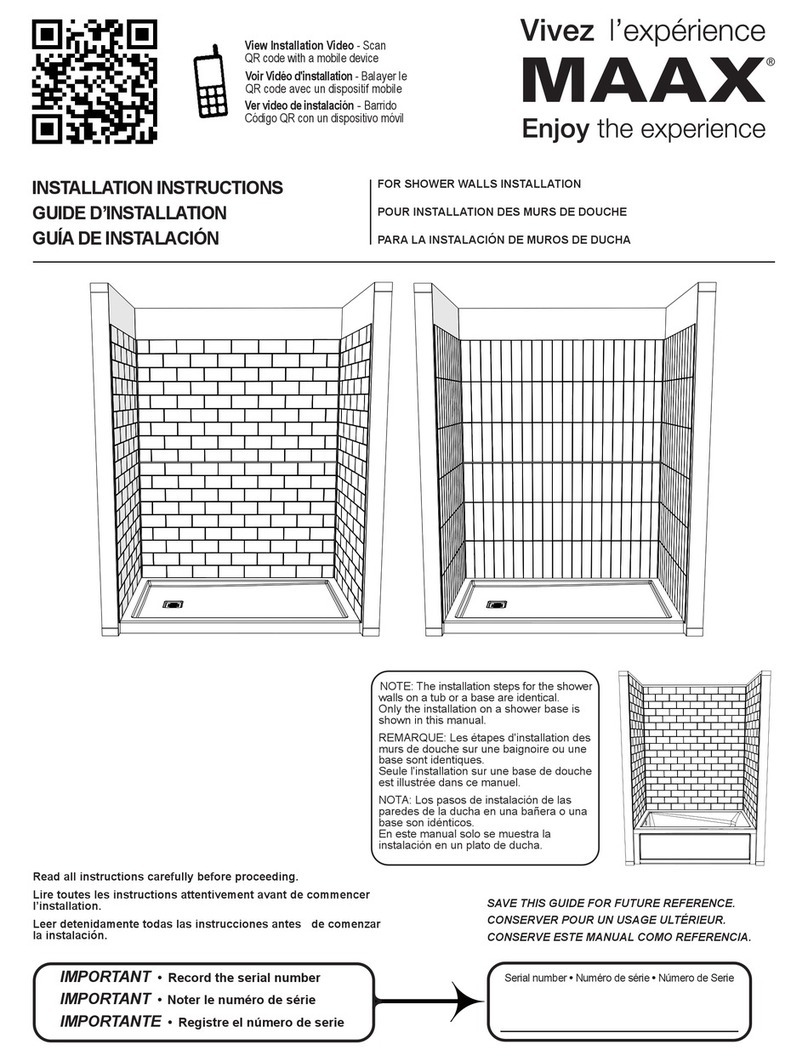

Bodywrap Whirlpool System

Assembly And Operation Guide

-4- 10023064

Through routine use, the whirlpool system

can collect residues from soap, bath

additives and natural body oils. Additional

deposits can also collect from minerals or

particles found in the water.

EXTREME CAUTION is urged regarding

the use of any cleaner, acid or solvent on

the whirlpool system trim.

> Check GFCI circuit breaker.

> Push on/off button to ensure system is

turned < ON >.

> Have wiring connections checked.

(Call installer or electrician).

> Thermal limiter (in pump) may have

engaged. (Call installer or supplier).

> Check air controls, confirm open.

> Check air controls, confirm open.

> Make sure water is to the top of the trim

ring on the highest jet.

> Check suction line connection at pump

intake port.

> Check highest side jet for blockage.

(Rotate internal jet cartridge counter-

clockwise for removal.

> Have pump checked for impeller

obstruction or other malfunction. (Call

installer or supplier).

> Confirm side or foot jets are open to full

flow. (Adjust center internal jet cartridge

counterclockwise for removal).

> Have pump-to-jet supply line checked

for blockage. (Call installer or supplier).

> Clean and service whirlpool system.

(See Whirlpool System Care and

Cleaning section.

> Confirm pump-motor is plugged in.

> Confirm air hose from on/off switch to

the pump motor is securely in place

and is not crimped.

Close the drain and fill tub to

desired water level. Water level

must be at least to the top of trim

ring on highest jet before whirlpool

system is started. (See Figure 4).

Before using the whirlpool for the first

time, the system should be cleaned as

described in the Whirlpool System Care

and Cleaning section of this guide.

The following procedure is recommended

to remove most deposits and avoid

major accumulations inside the system

piping. The actual schedule for cleaning

will depend on system usage and water

quality, but should not exceed 90 days.

Fill tub to the top of the trim ring

on the highest jet with lukewarm

water. (Figure 4)

Add 1 cup low-sud-sing automatic

dishwater detergent and run the

whirlpool system for 20 minutes

(1 complete timer cycle)

Drain tub, refill with clean water and

operate the system for 20 minutes

(1 complete timer cycle) to rinse.

(Rinse thoroughly)

Occasionally sanitze the system by following

the cleaning procedure above, but subsitute

1 cup of household bleach for the

dishwasher detergent.

(Rinse very thououghly)

Refer to the unit installation for guidelines

on the unit surface care and cleaning.

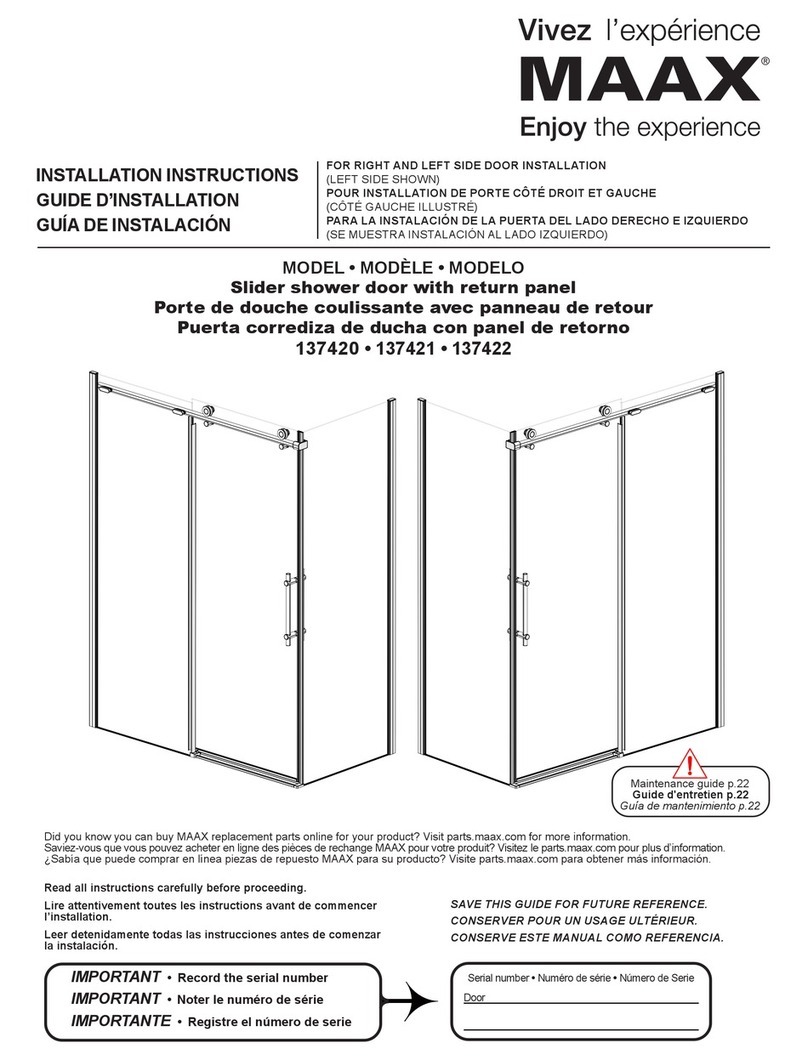

Check both air controls as shown

in Figure 5. Avoid starting the

whirlpool with the air controls in

the fully closed position.

If the air controls are tightly closed,

rotate the knob counterclockwise

one-half revolution before starting

the system.

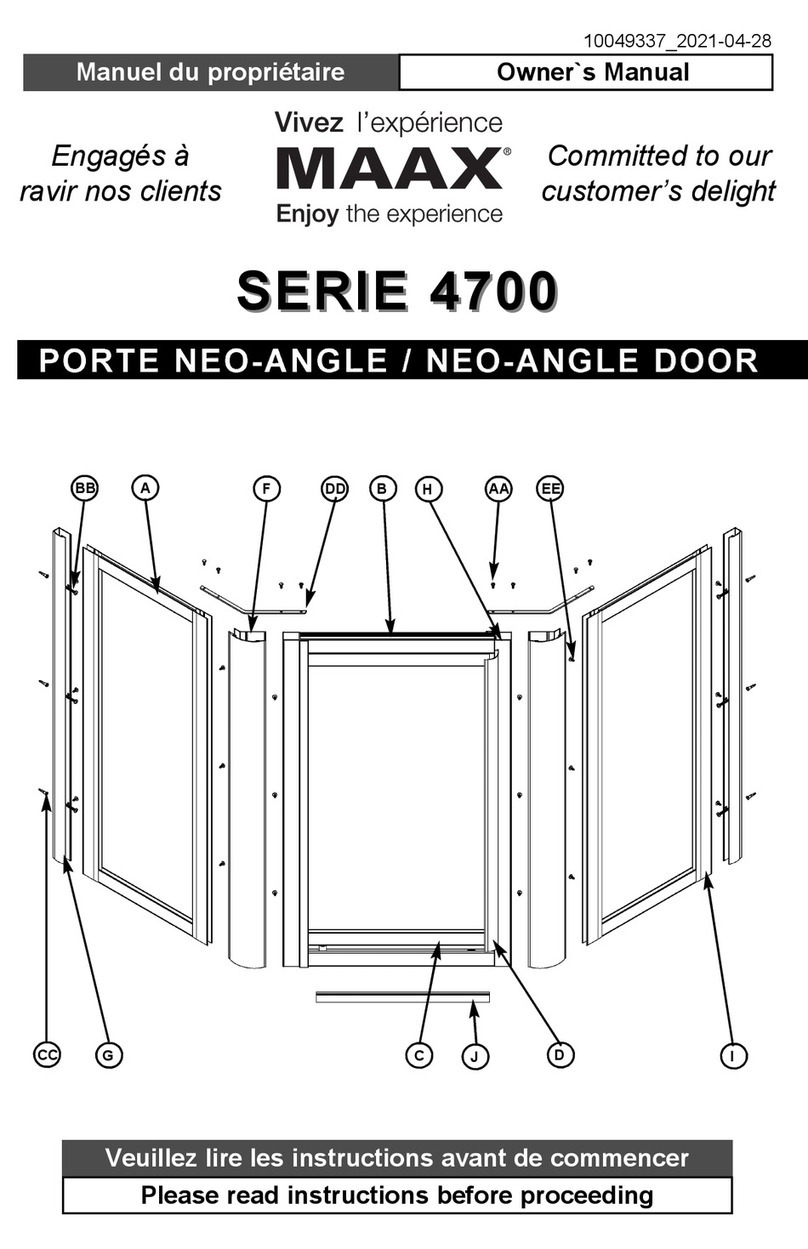

To start the whirlpool, gently touch

the button as shown in Figure 6.

The built-in 20-minute timer cycle

automatically begins when the

system is started.

To stop the whirlpool during the

timer cycle or to restart the system,

gently touch the switch button.

On systems equipped with an in-line

heater, the heater is automatically

operated though the internal heater

controls.