Cooling Operation (Defrosting Adaptable)

During the cooling operation, the main control board

monitors door openings (cooler and freezer doors) and

operating time of the compressor. The length of time

between consecutive defrosts is reduced by each open

door. If the doors are not opened, the compressor will

work up to 60 hours between defrosting. If the doors open

frequently and / or for long periods, the operating time of

the compressor between defrosting will be reduced to as

little as 8 hours

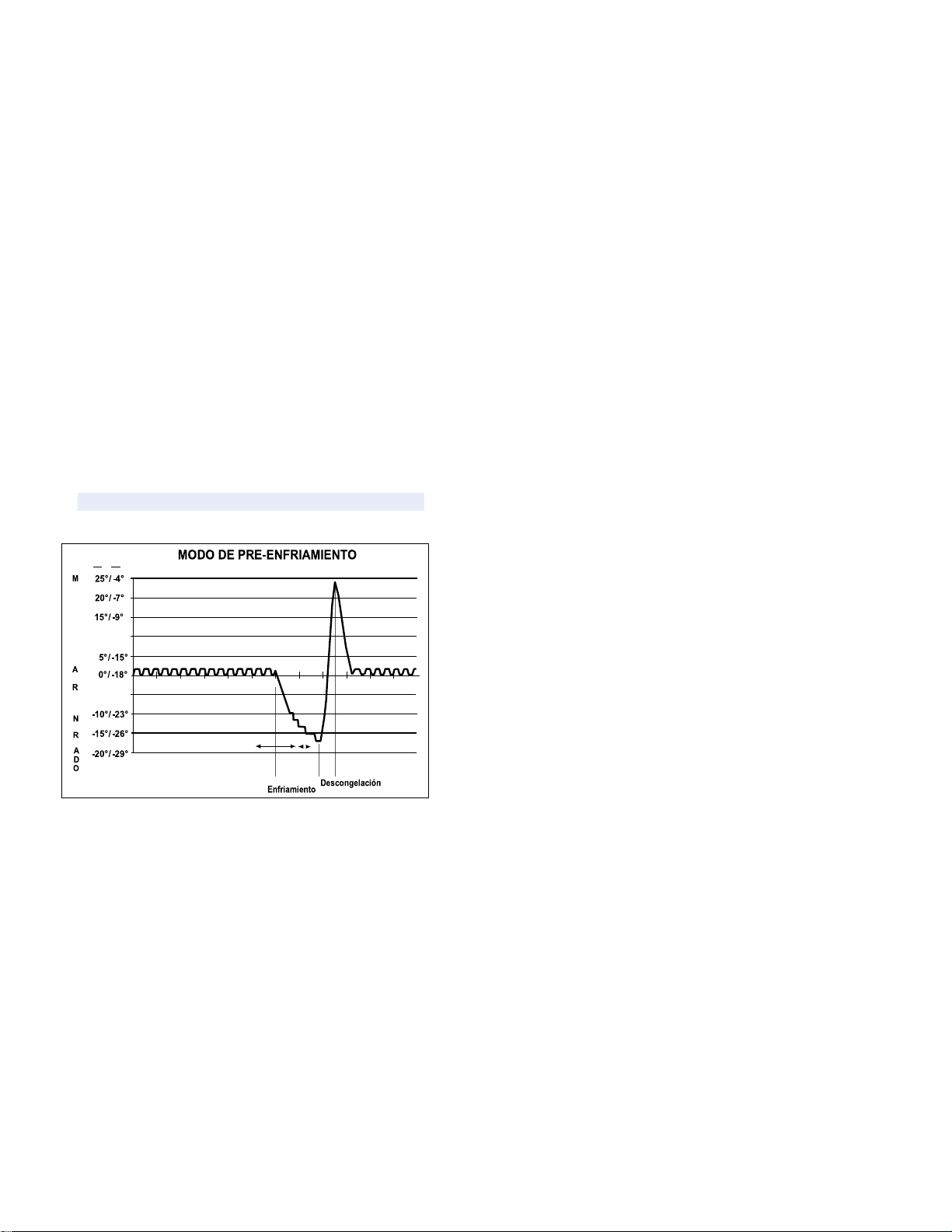

Pre-Cooling Operation (Defrosting

Adaptable)

When the main control board determines that the

defrosting is necessary, the main control board will force

the refrigerator to a continuous mode cooling (pre-

cooling). During pre-cooling, the freezer temperature can

be carried down the set point temperature of the control

panel screen. However, the temperature of the cooler will

be regulated by the shock absorber Pre-cooling and will

last 2 hours if it is not interrupted by some open door. If

after 8 hours, the unit could not complete a pre-cooling

without interrupting, the defrost cycle will continue.

Operation of the defrost heater

After 2 hours of pre-cooling operation or 8 hours of

interrupted pre-cooling attempts, the main control board turns

off the compressor, condenser fan and the evaporator

fan. The main control board then energizes the defrost relay,

which completes the Defrost Cycle.

A thermostat-defrosting (switch) protects the defrosting

system. The thermostat opens when the evaporator

temperature rises to 140 ° Fahrenheit and closes when the

evaporator temperature drops to 110 degrees Fahrenheit.

Rest Period (Adaptive Defrosting)

After the main control board has completed the operation of the

defrosting heater, there is a resting period of 5 minutes. During

this period, the compressor, condenser fan and evaporator fan

they stay off. Frost melting that remains of the evaporator will

continue to fall and drain to that the evaporator to be completely

clean of any humidity before the cooling operation. After 5

minutes of resting period, the unit enters a post break.

Post Rest (Adaptive Defrosting)

The post-rest period is designed to cool the evaporator before

circulating the air inside the refrigerator. This prevents any

residual heat in the evaporator from being distributed in the

freezer. During this period, the compressor and the condenser

fan are on, but all the interior fans are off and the shock

absorber is turned off. Post-rest times vary with the different

Models. However, there is a maximum of 5-minutes

of resting time.

Liner Protection Mode

The liner protection mode will be activated if any of the doors

have been opened for 3 minutes. This mode will start the fans

and will close the damper. This mode is controlled by 2

timers. Timer # 1 monitors door open time. A 3-minute open

count. The door will start when the door is opened. If it passes

3 minutes before the door is closed, the protection mode of

lining will be activated. Once the door is closed, timer # 1 is

reset and the liner protection mode passes to reserve. In

reserve, normal fan and damper operations begin and timer #

2 begins a count of 3 closed door minutes. If you spend 3

minutes without opening the door, the liner protection mode will

be completely deactivated. If a door is opened within the timer

#2 coun 2 closed door, the remaining time in door counting

closed the count of timer # 1 of open door will be deducted.

During the defrosting operation, the main control board monitors

the evaporator temperature using inputs to the evaporator

thermistor. The thermistor will usually end the operation of the

thermistor heater in less than 20 minutes. The typical thawing

time is 20-30 minutes.

- 8 -