1

1

Contents

Chapter 1 General Information .......................................................................................................................2

1-1. General Guidelines..................................................................................................................................2

1-2. Insurance test ..........................................................................................................................................2

Chapter 2 Product Feature .............................................................................................................................3

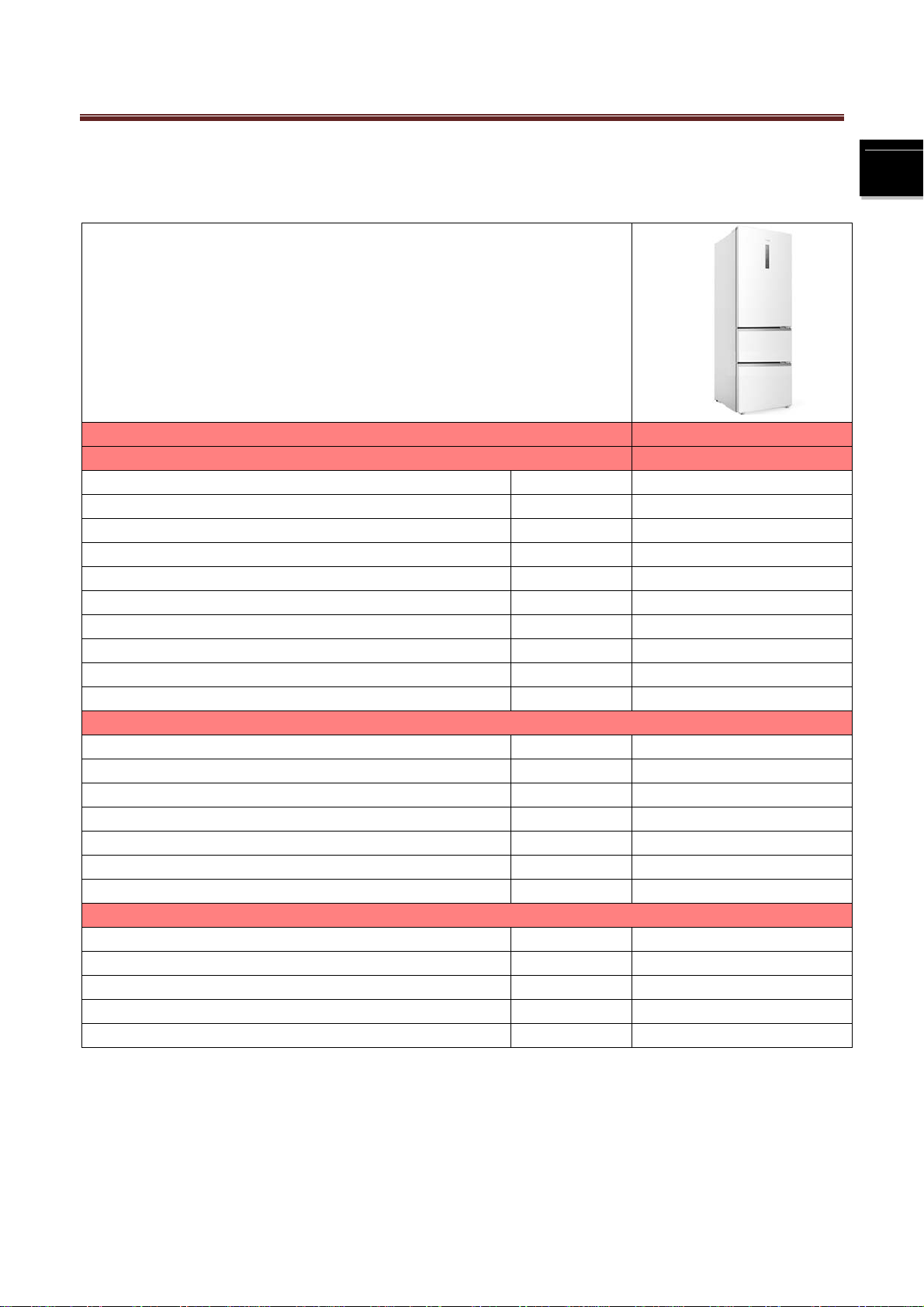

2-1. Specifications...........................................................................................................................................3

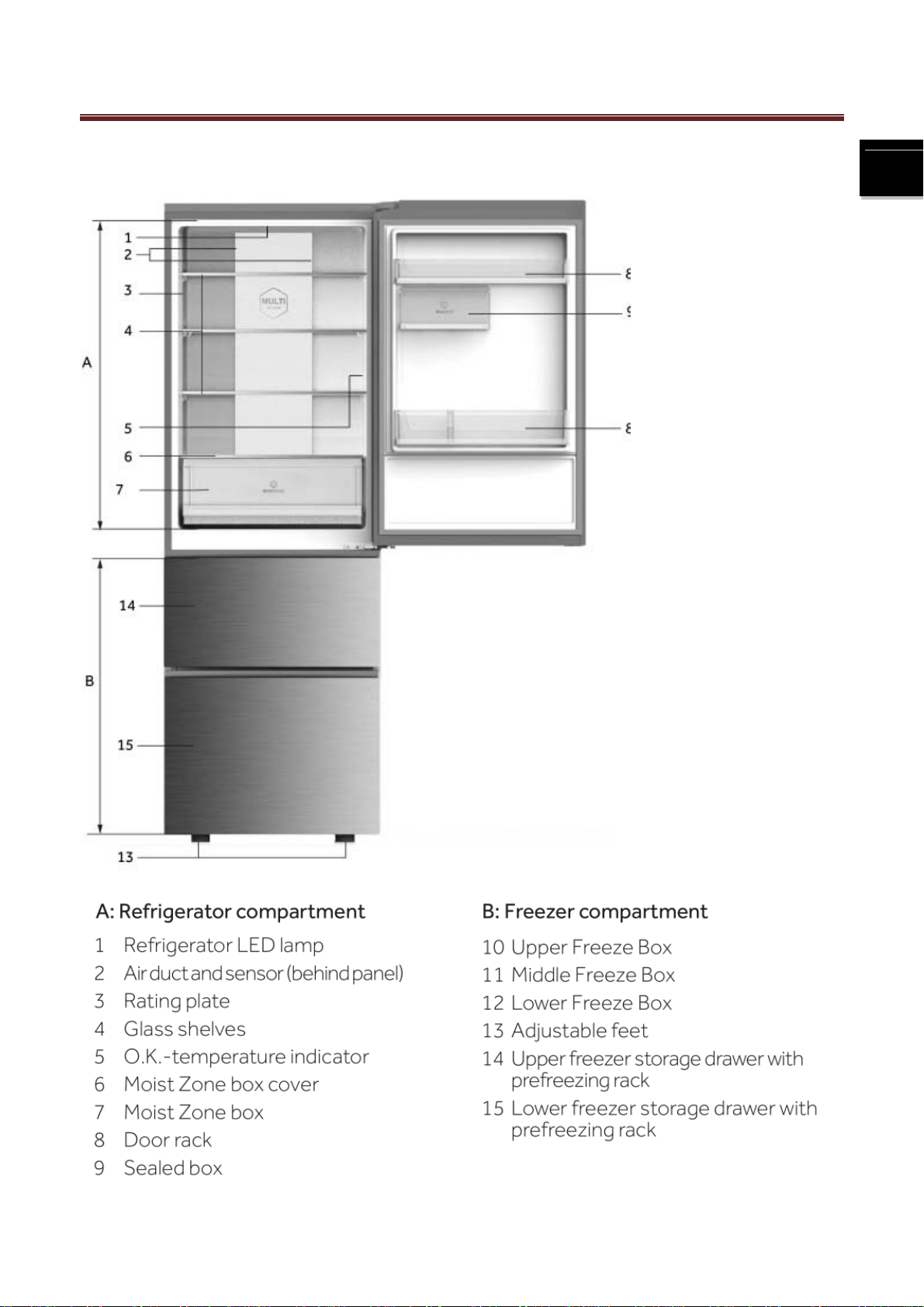

2-2. External views..........................................................................................................................................4

2-3 Space requirement....................................................................................................................................5

2-4. Main features...........................................................................................................................................5

Chapter 3 Disassembly and Installation..........................................................................................................6

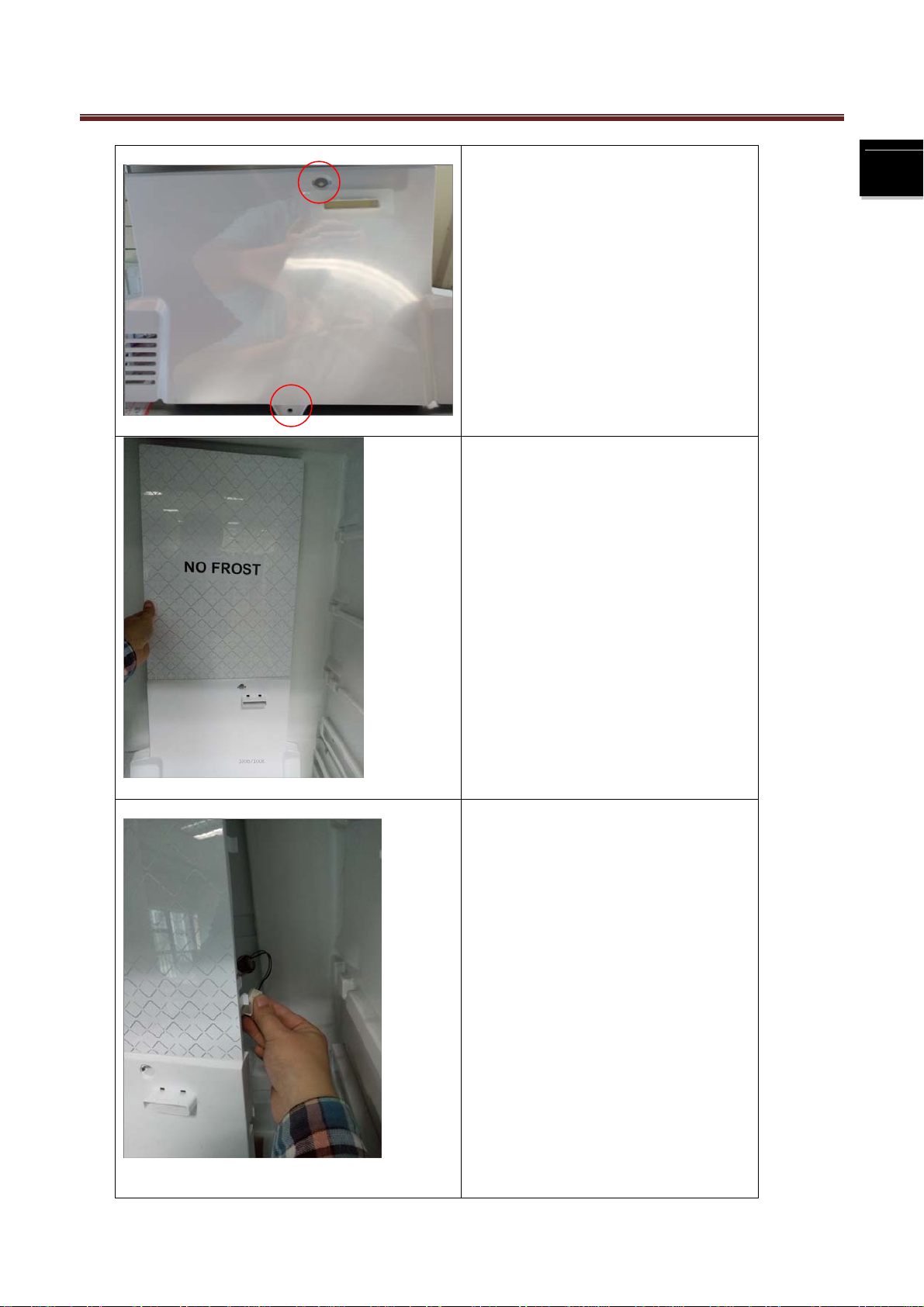

3-1 Disassembly of the assembly...................................................................................................................6

Chapter 4 System flow principle ...................................................................................................................12

4-1. Refrigeration flow chart..........................................................................................................................12

4-2 Refrigerating cycle perspective...............................................................................................................13

Chapter 5 Circuit diagram.............................................................................................................................14

5-1. Brief principle diagram...........................................................................................................................14

5-2. Main control Chart .................................................................................................................................15

5-3.Connectors ‘ location on PCB..............................................................................................................16

Chapter 6 Main Function Operating principle...............................................................................................17

6-1 Defrost system .....................................................................................................................................17

Chapter 7 Control and display system..........................................................................................................19

7-1 Control and display panel.......................................................................................................................19

7-2 Function adjustment ...............................................................................................................................19

Chapter 8 Quick check and Self-test model .................................................................................................21

8-1 Checking method of fault code.............................................................................................................21

8-2 Test mode ...............................................................................................................................................21

8-3 Demo mode ............................................................................................................................................22

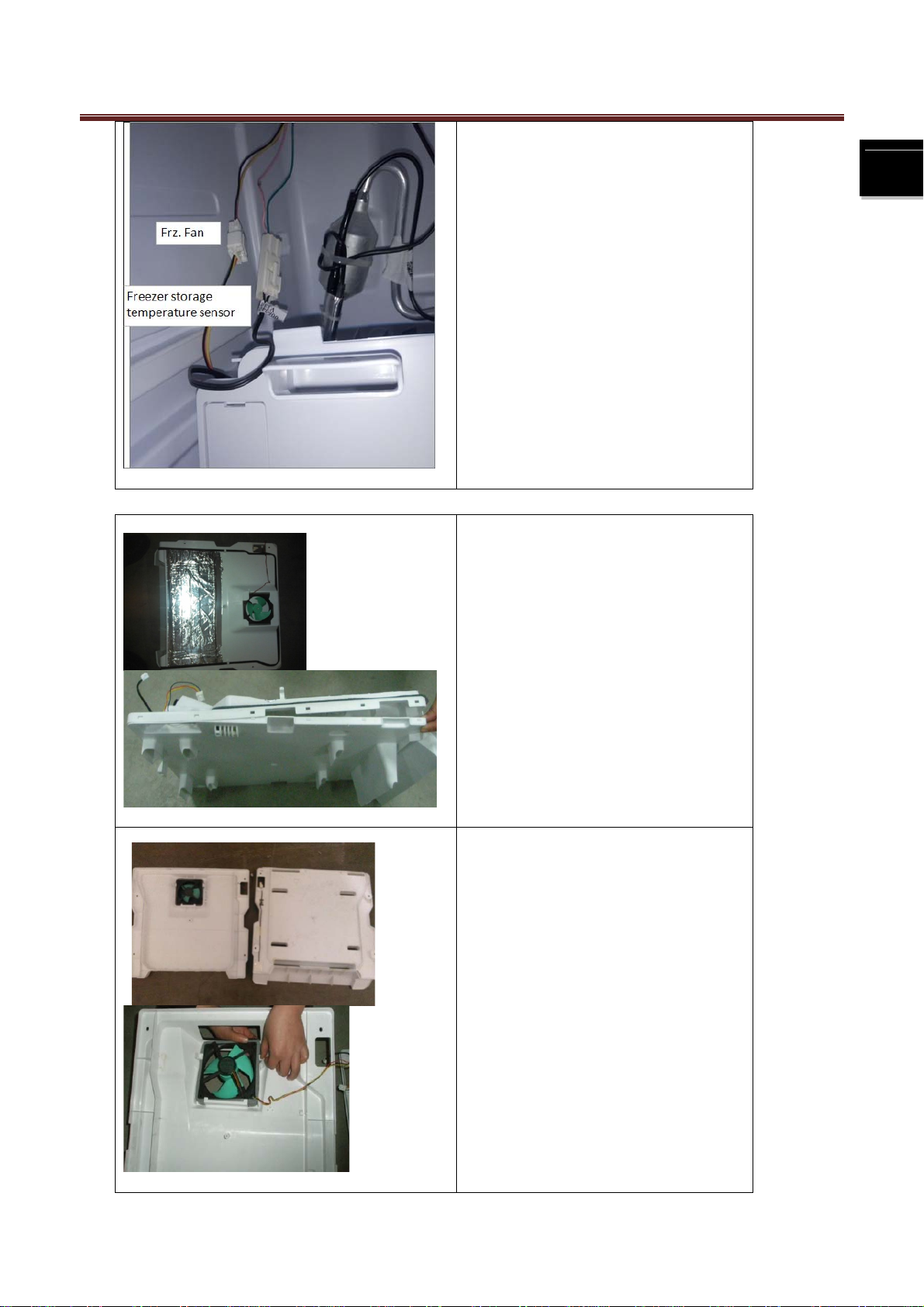

8-4 Sensor layout plan..................................................................................................................................23

Chapter 9 Electrical Parts specifications.......................................................................................................24

Chapter 10 Trouble shooting.........................................................................................................................25

10-1. Symptom: No freezing.........................................................................................................................25

10-2. Symptom: no shutdown.......................................................................................................................26

10-3. Symptom: Poor freezing......................................................................................................................27

10-4. Symptom: No starting when powering on............................................................................................28

10-5. Symptom: no defrosting.......................................................................................................................29