214286 vRevision C

List of Revisions .........................................................................................................................................i

Introduction.............................................................................................................................................. iii

Chapter 1: Safety .................................................................................................................................... 1

1.1 Safety Alert Symbols ............................................................................................................................1

1.2 Signal Words .......................................................................................................................................2

1.3 General Safety.....................................................................................................................................3

1.4 Maintenance Safety .............................................................................................................................5

1.5 Hydraulic Safety...................................................................................................................................6

1.6 Welding Precaution ..............................................................................................................................7

1.7 Safety Signs ........................................................................................................................................8

1.7.1 Installing Safety Decals ...............................................................................................................8

1.8 Safety Sign Decals...............................................................................................................................9

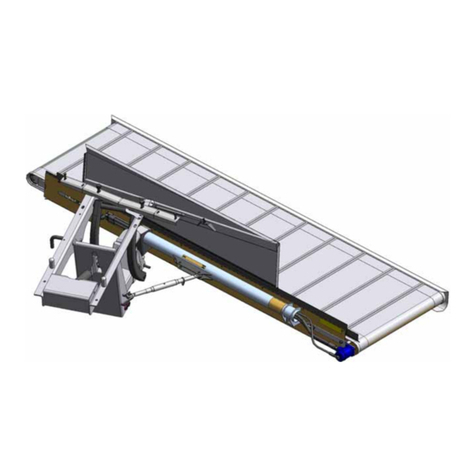

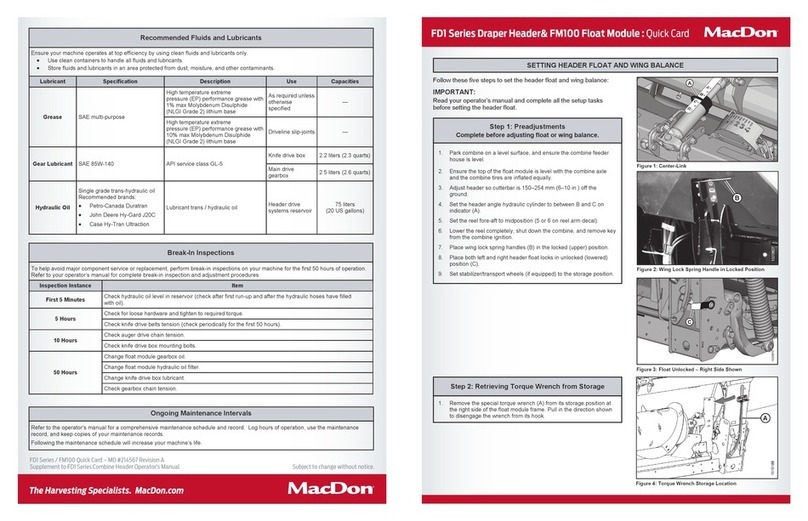

Chapter 2: Assembly Instructions.................................................................................................... 11

2.1 Removing Swath Compressor from Shipping Crate .............................................................................. 11

2.2 Installing Swath Compressor on M1 Series Windrower .........................................................................15

Chapter 3: Operation ........................................................................................................................... 27

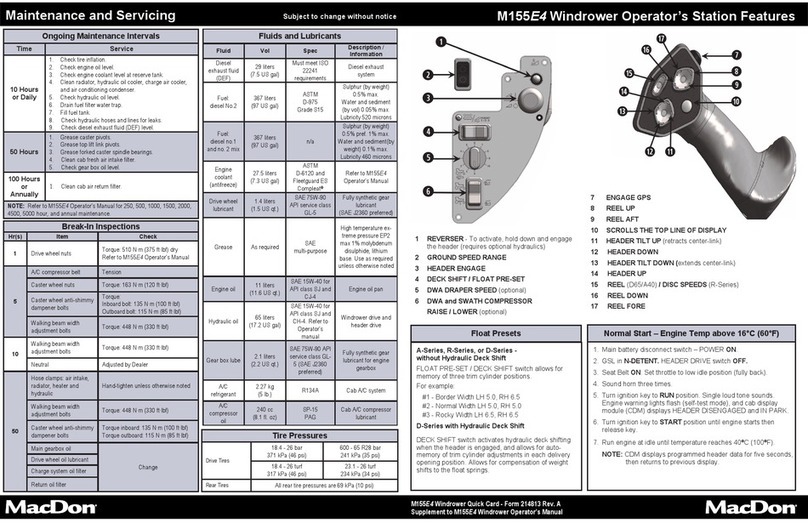

3.1 Activating the Swath Compressor........................................................................................................27

3.2 Operating the Swath Compressor........................................................................................................29

3.2.1 Setting up the Swath Compressor ..............................................................................................31

3.2.2 Programming One-Touch-Return................................................................................................32

3.2.3 Adjusting Down Force ...............................................................................................................32

3.2.4 Adjusting Side Deflectors ...........................................................................................................33

3.2.5 Operating the Swath Compressor Lock .......................................................................................34

3.3 Removing the Swath Forming Shield ...................................................................................................35

Chapter 4: Parts .................................................................................................................................... 37

4.1 Swath Compressor Frame –Parts List.................................................................................................38

4.2 Swath Compressor Hydraulics and Supports –Parts List ......................................................................42

4.3 Decals...............................................................................................................................................46

Chapter 5: Reference ........................................................................................................................... 49

5.1 Torque Specifications .........................................................................................................................49

5.1.1 Metric Bolt Specifications ...........................................................................................................49

5.1.2 Metric Bolt Specifications Bolting into Cast Aluminum ..................................................................51

5.1.3 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable) ......................................................................52

5.1.4 O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable)...............................................................54

5.1.5 O-Ring Face Seal (ORFS) Hydraulic Fittings ...............................................................................55

5.1.6 Tapered Pipe Thread Fittings .....................................................................................................56

5.2 Conversion Chart...............................................................................................................................57

TABLE OF CONTENTS