-19-

-Never work without the protective equipment

required for the work to be undertaken and never

modify anything on the machine that could impair

safety.

-Children and adolescents must not operate this

machine. This rule does not apply to young

persons receiving training and being supervised by

an expert.

-Before working with the machine, always check to

ensure that the protective and safety devices are

firmly in place and undamaged, that they work

faultlessly and that the the moving protective hood

works without getting stuck.

-Consider environmental influences. Do not expose

the machine to rain and avoid working in damp and

wet areas as well as near combustible liquids and

gasses.

-When operating the machine outdoors, use of an

earth-leakage circuit-breaker is recommended.

-Do not carry the machine by its cable and do not

use the cable to pull the plug out of the socket

outlet.

-Pay attention that the cable is protected against oil

and heat and is not pulled across sharp edges.

-Damaged cables or plugs must be immediately

replaced.

-Avoid sharp bends in the cable. Especially when

transporting and storing the machine, do not wind

the cable around the machine.

-Use only cutter heads with the specifications

indicated in this operating manual.

-Store the machine in a dry, locked place outside

the reach of children.

Instructions on the use of personal protective

equipment:

-Always wear ear protectors during work.

-Always where a dust mark during work.

-Always wear protective goggles during work.

Instructions on operation:

-Provide for an unobstructed and slip-proof location

with adequate lighting.

-Unplug the power cord before changing tools,

making adjustments or rectifying faults (including

the removal of jammed chips).

-Do not work on workpieces which are too small or

too large for the capability of the machine.

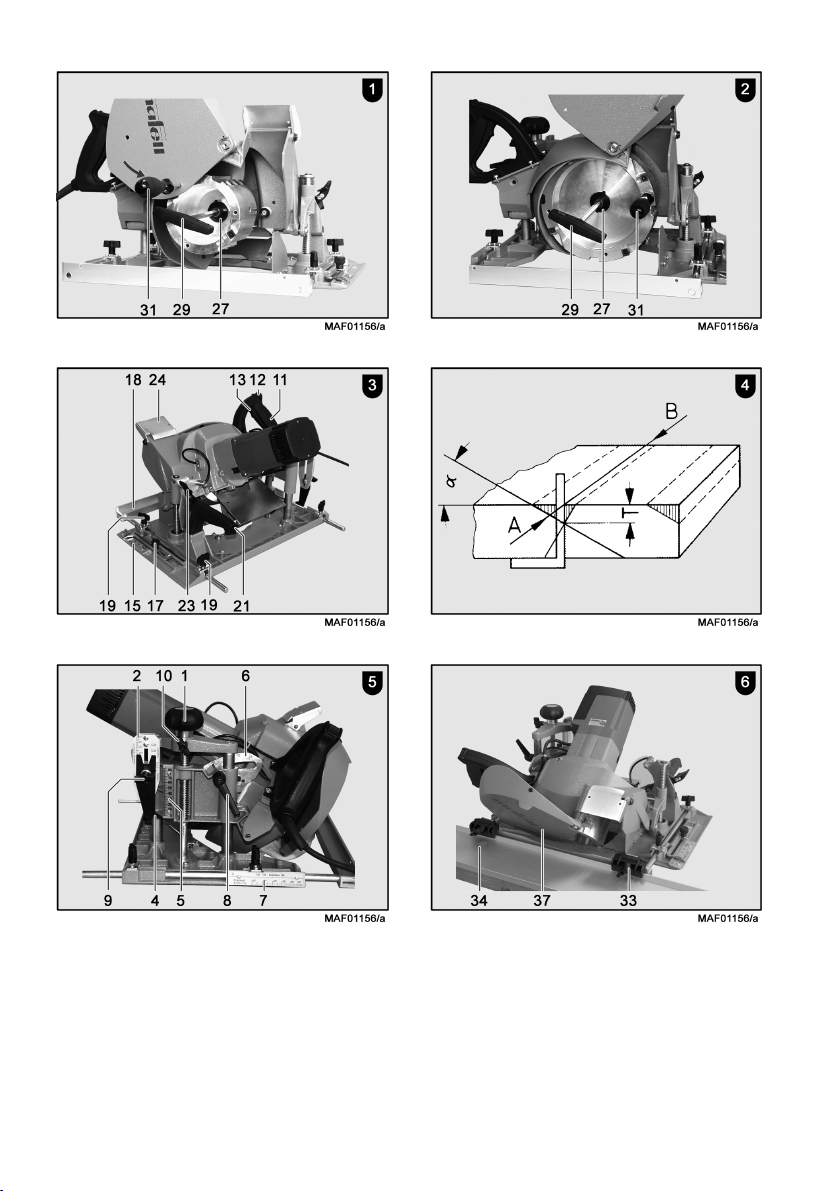

-Install and fasten the cutter head properly. Use

sharp cutters and taper taps; dull cutters increase

the risk of kickout. Immediately replace damaged

cutters and taper taps and fasten them so that they

cannot become loose operation.

-The moving protective hood must not be blocked

when open.

-The switch may not be wedged.

-Before switching on the machine, always check

whether the cutter head is tightened and whether

the wrench and pin have been removed.

-If possible ensure that the workpiece is secured

from slippage, e.g. with tension clamps.

-Hold firmly onto the machine before switching it on.

-Begin cutting the workpiece only when the cutter

head reaches its full speed.

-Examine the workpiece for foreign objects. Do not

cut into metal parts, e.g. nails.

-Never reach under the workpiece while cutting

(risk of injury!).

-When cutting always have the connecting cable

behind the machine.

-An even forward feed when cutting extends the

service life of the cutting bit and the machine. Do

not cut backwards or by dipping.

-Remove the machine from the workpiece only

when the cutter head is at a standstill.

-Never touch the cutter head or reach into the chip

ejector while the machine is running. Always

switch off the machine before making adjustments

and ensure that the cutter head has come to a

standstill.

-Set the machine down only when the moving

protective hood is closed. Do not clamp the moving

protective hood or end guard, and ensure that they

work properly. Do not remove protective parts.

-The bird's head cutter may be used only outside or

in open areas, as effective extraction is not

possible.

Instructions on service and maintenance:

-Regularly cleaning the machine, especially the

adjusting devices and guides, constitutes an

important safety factor.