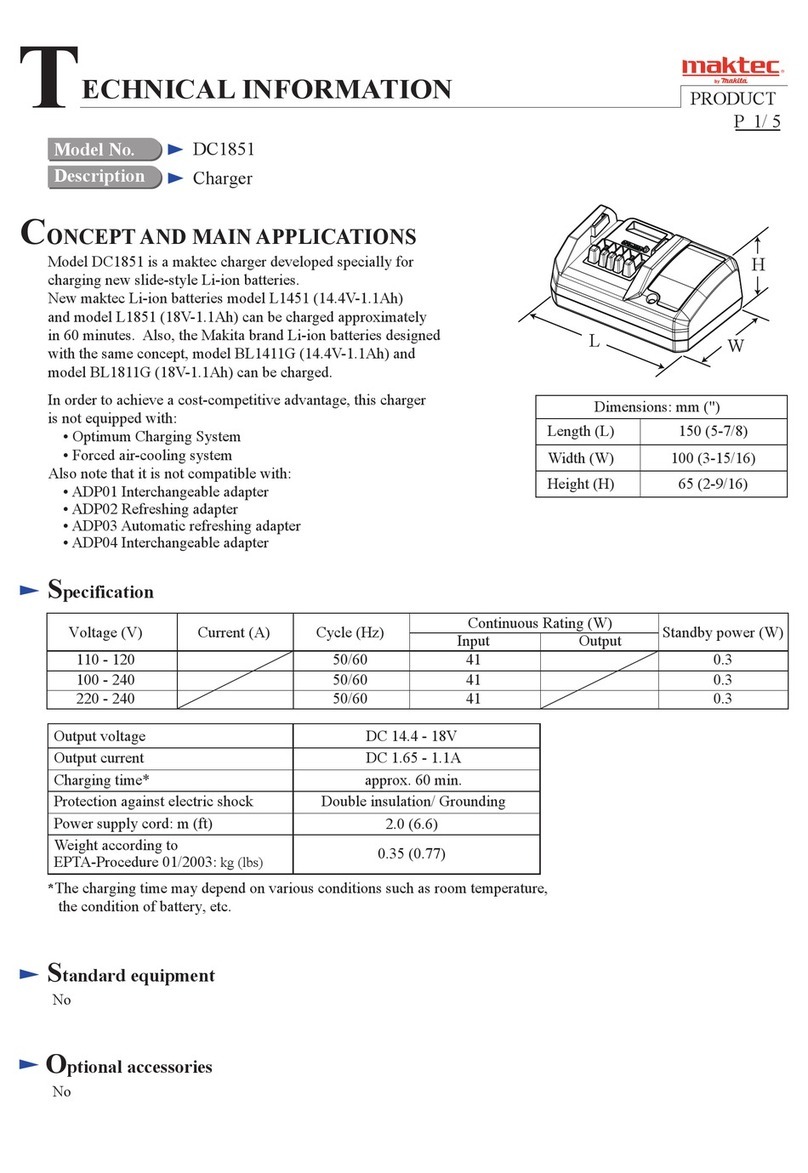

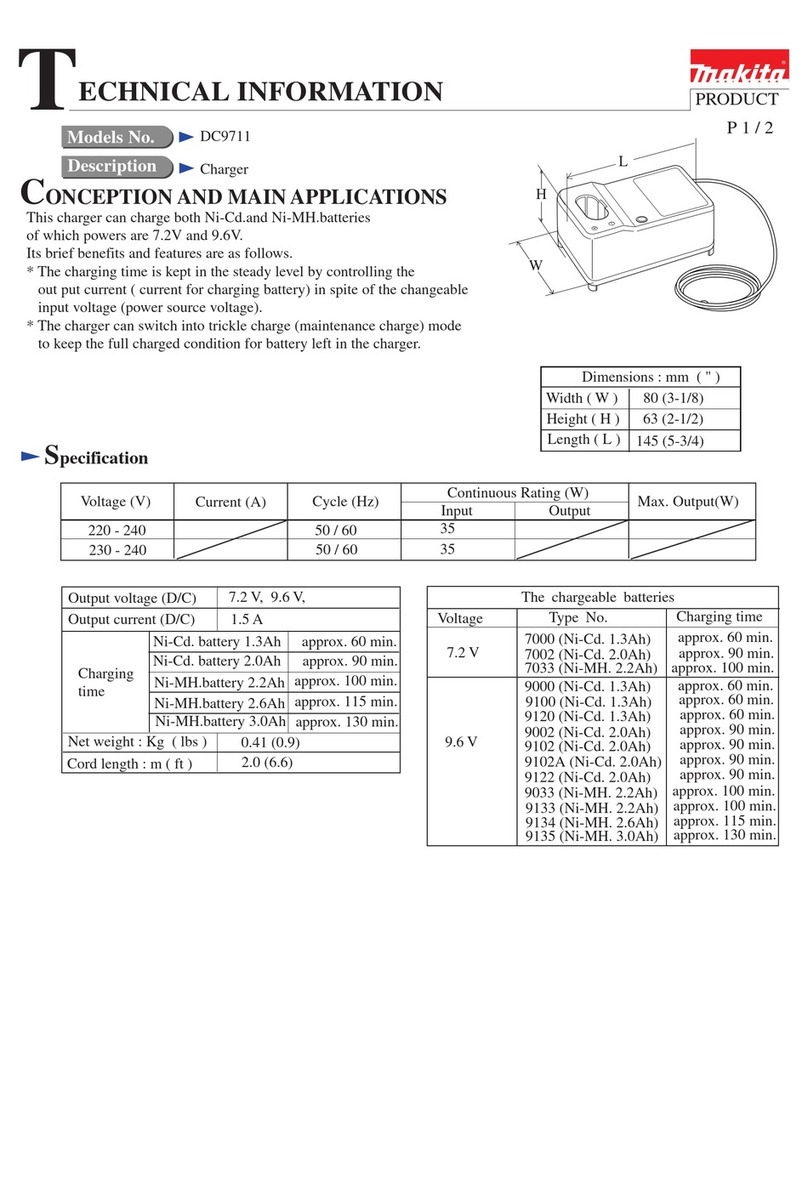

Features and benefits P 2 / 8

Chargeable for 7.2V - 24V

batteries

Longer life of battery

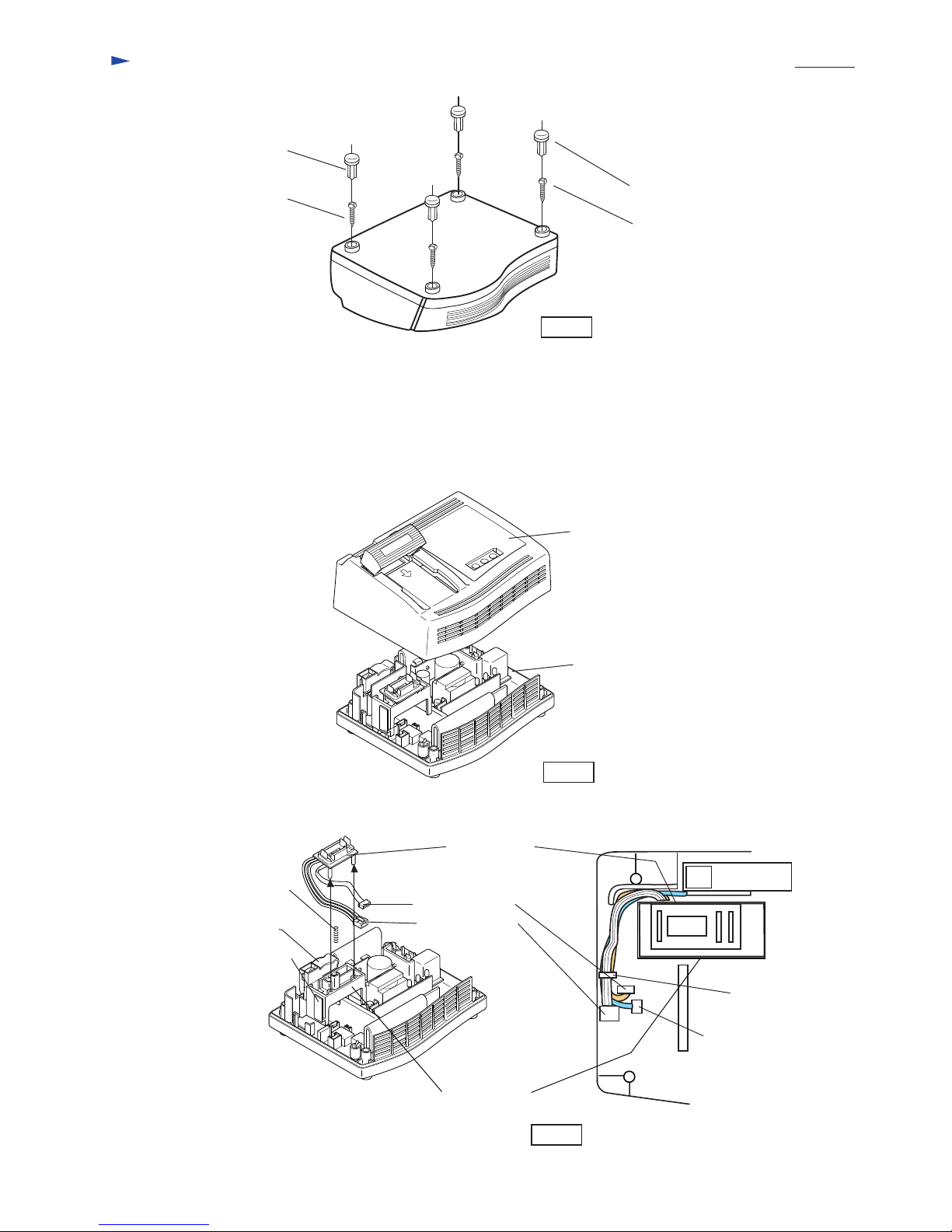

2. Cooling system

The cooling fan prevents the over heat on battery and keep the optimum temperature for charging.

3. The charging control system

This system controls the output current depending on the temperature on the battery in charging process.

The following innovative systems extend the battery's life approx.50% longer.

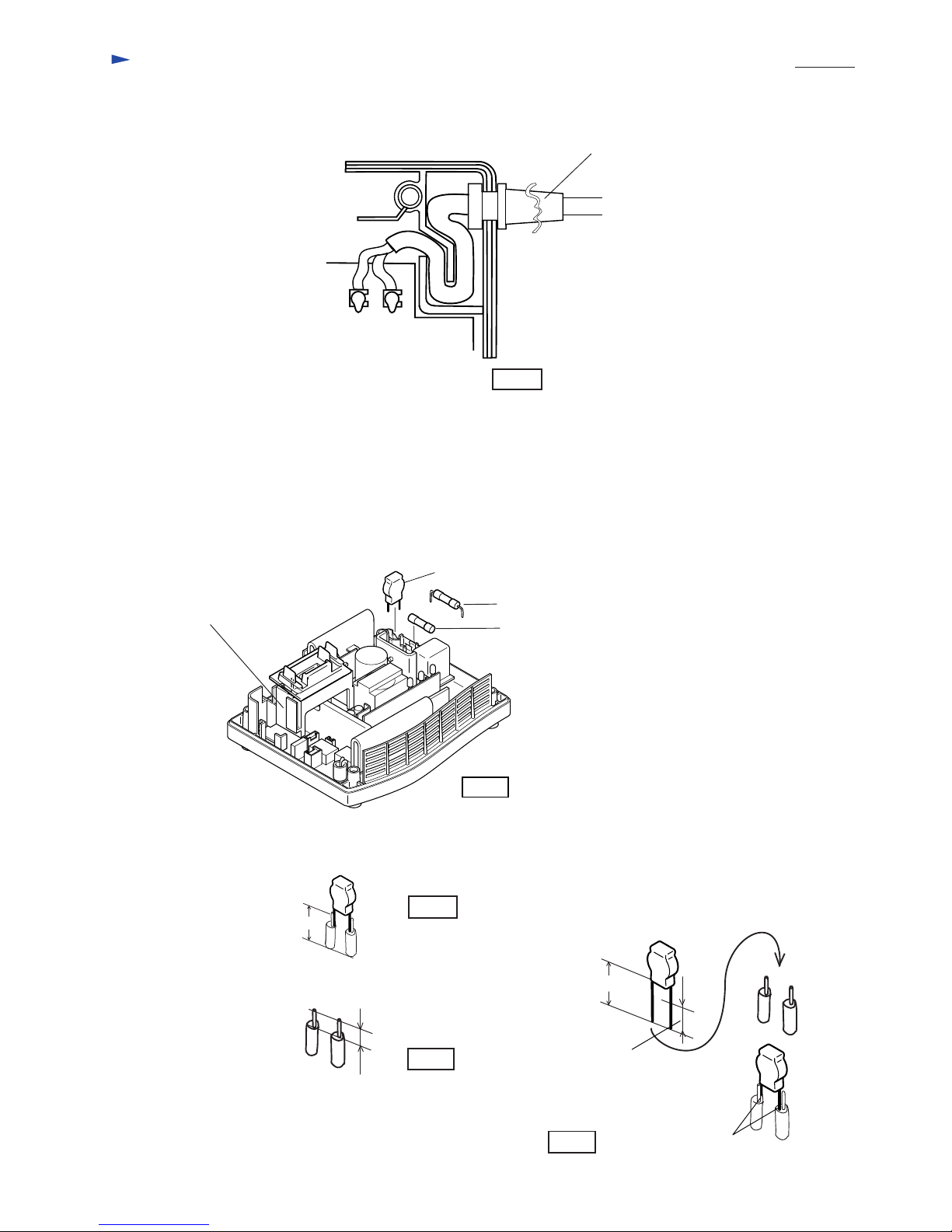

1. Conditioning charge

The charger receives distinctive data (temperature, history of usage ect.)

from built-in memory chip installed in battery, and decides the most suitable conditions to charge the battery.

The conditioning charge will start, when the battery is employed repeatedly under the following conditions,

which have bad influence on battery's life.

1. Charge under high room temperature (higher than 40°C)

2. Charge under low room temperature (lower than 10°C)

3. Recharge for full charged battery

4. Over discharge (continue to discharge battery in spite of machine's power down.)

Even if the cooling system does not work (because of breakdown of fan or obstruction of vent etc.),

the conditioning charge functions and starts to charge selecting the most friendly method to the battery.

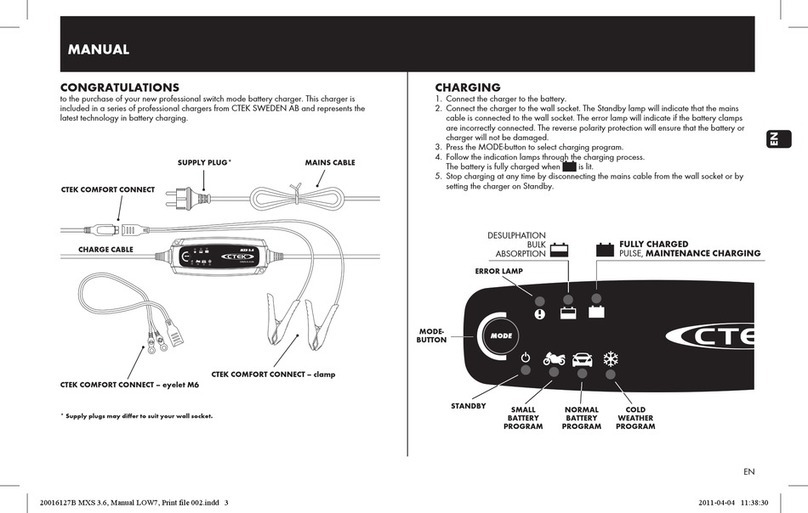

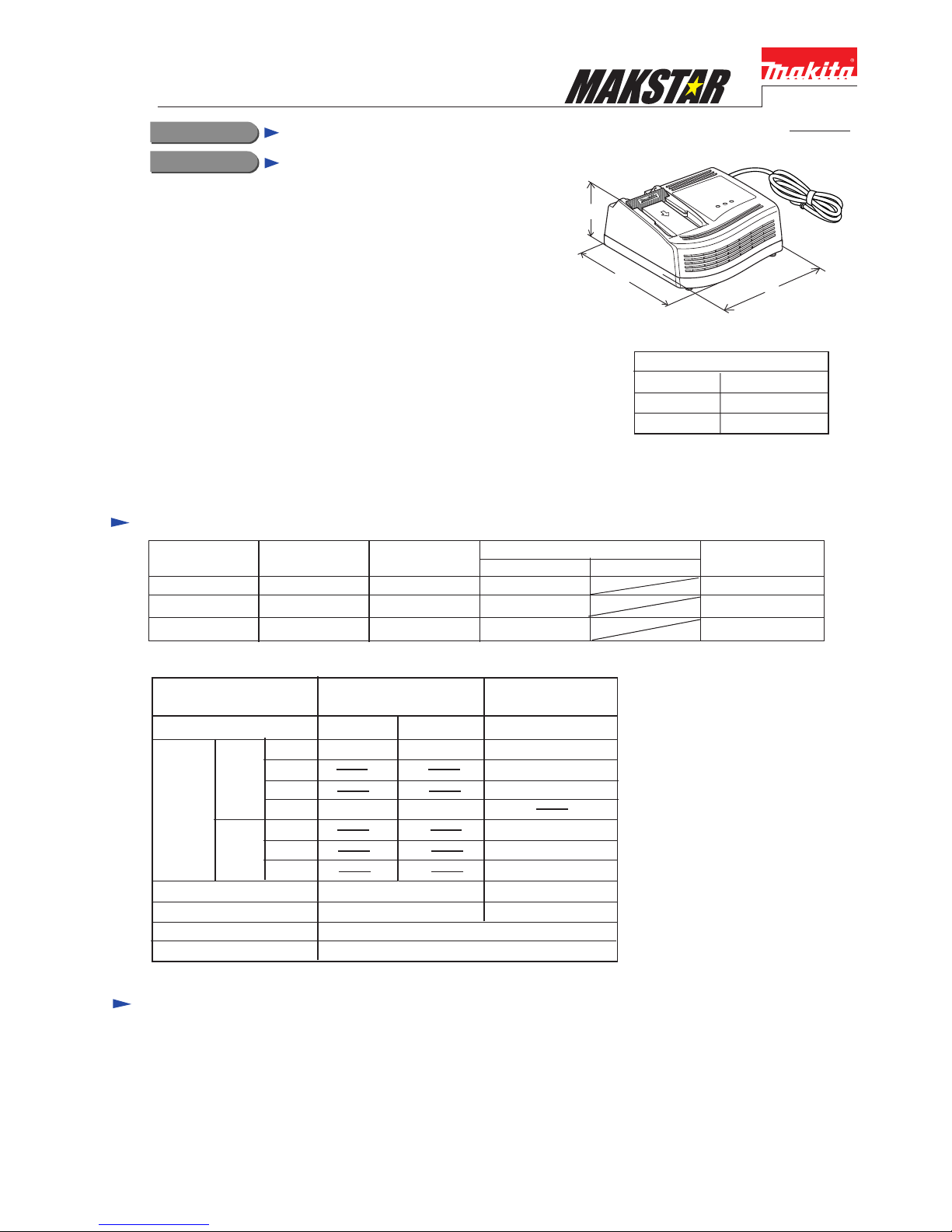

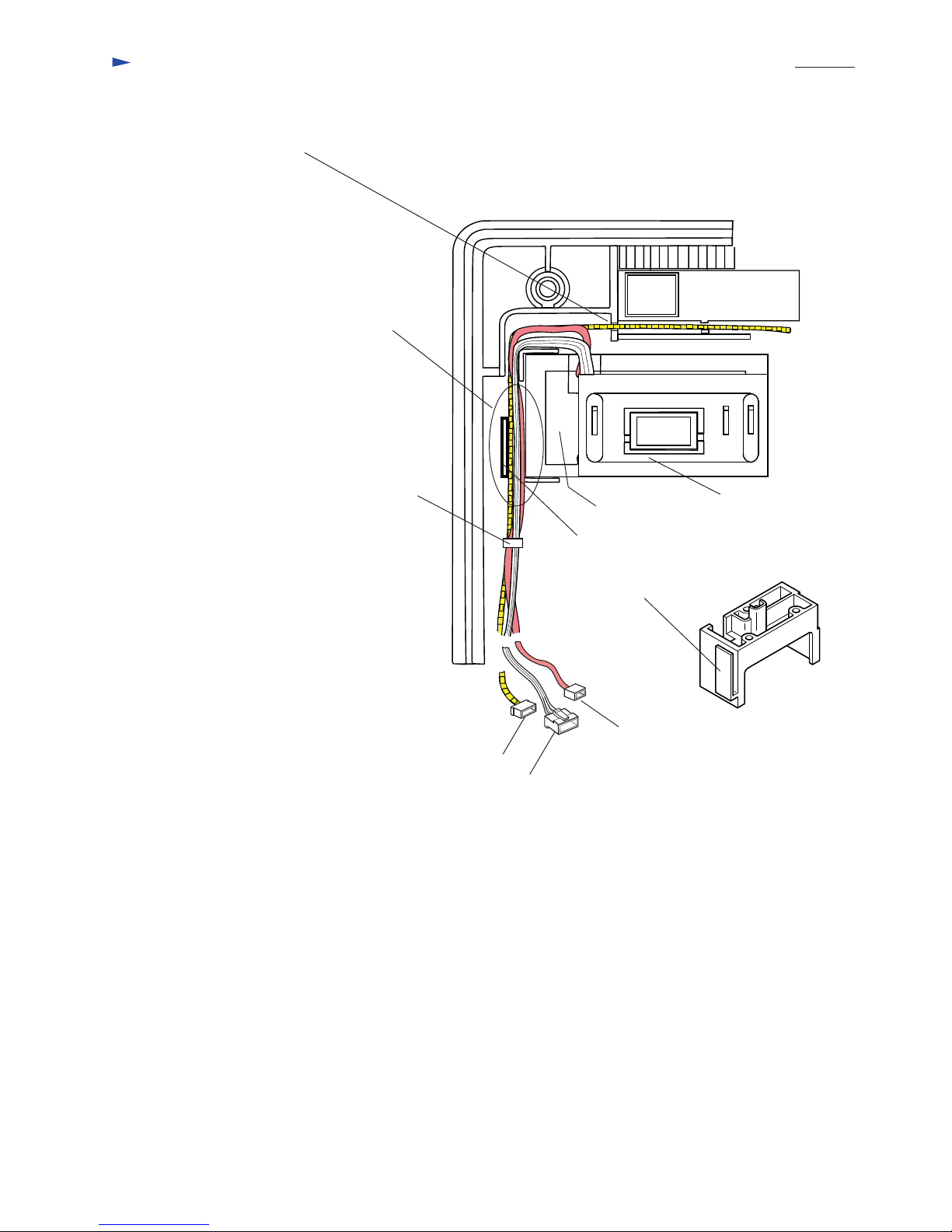

Charging light indicating charging

process and charging condition

with red, green and yellow

Charging light

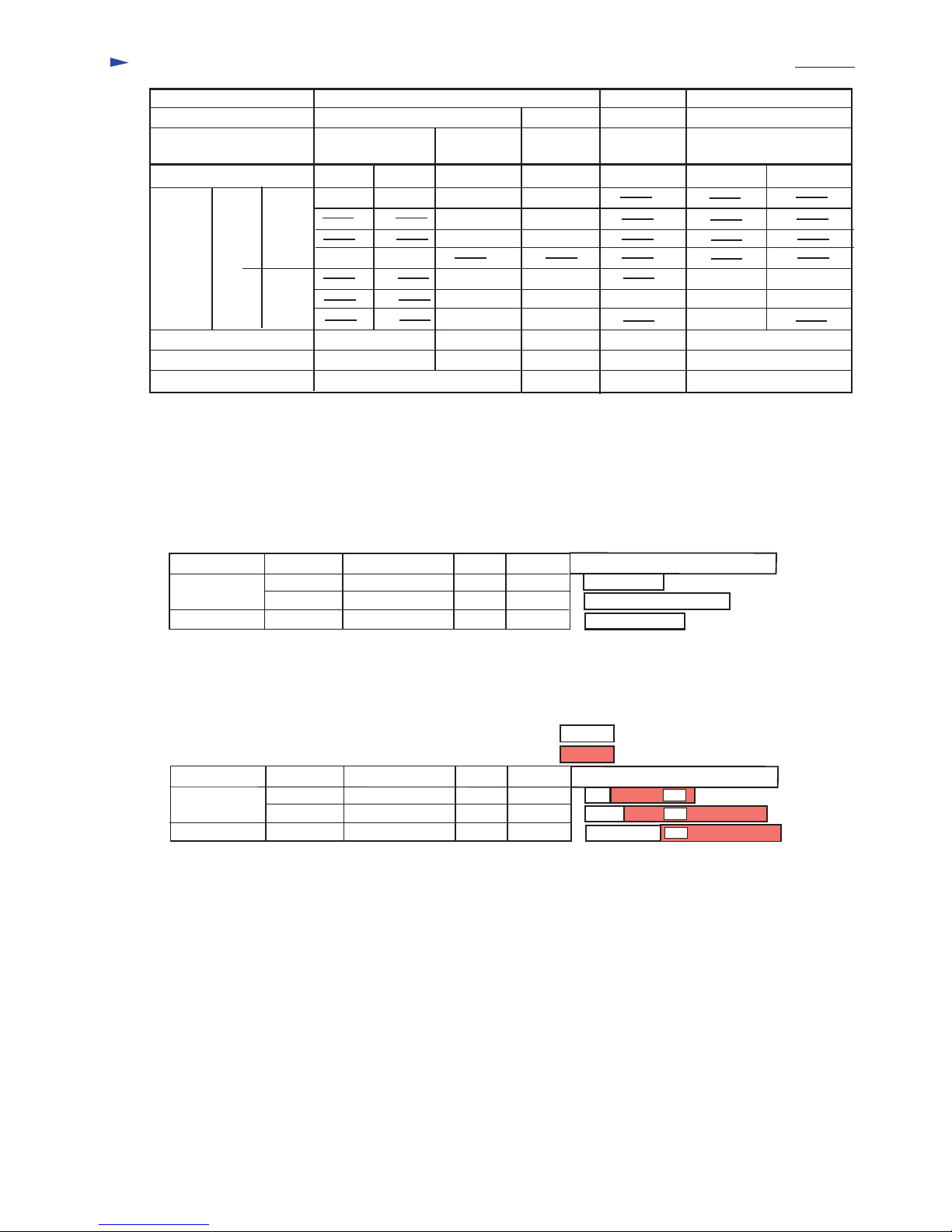

Mark Condition

Two green lights flash, when the charger

is connected to the power source.

One red light is on, when the battery

cartridge is inserted into the charger.

Stand by to charge.

Two red lights are on.

Two green lights are on,

indicating the charged condition in 0 - 79%.

indicating the charged condition

in more than 80%.

Finish of charge.

Two red lights flash,

One red light flashes.

Red and green lights flash alternately. Impossible to charge, because

* the life of battery is over.

or

* the vent on charger or battery is clogged.

Cooling the inserted battery.

Its temperature is higher than 70°C.

The charge is stopped until the battery is cooled.

Cooling the inserted battery.

Its temperature is lower than 70°C.

The charge is stopped until the battery is cooled.

One yellow light is on

One yellow light flashes.

Conditioning charge is started.

The charging time can be longer than usual.

Breakage on cooling system

(The vent of charger or battery is clogged, or

the cooling fan is damaged.)

Charging lights