5

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

Installing or removing battery cartridge

Fig.1

• Always switch off the tool before installing or

removing of the battery cartridge.

•

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

• To install the battery cartridge, align the tongue on

the battery cartridge with the groove in the housing

and slip it into place. Always insert it all the way

until it locks in place with a little click. If you can see

the red indicator on the upper side of the button, it is

not locked completely. Install it fully until the red

indicator cannot be seen. If not, it may accidentally

fall out of the tool, causing injury to you or someone

around you.

• Do not use force when installing the battery

cartridge. If the cartridge does not slide in easily, it

is not being inserted correctly.

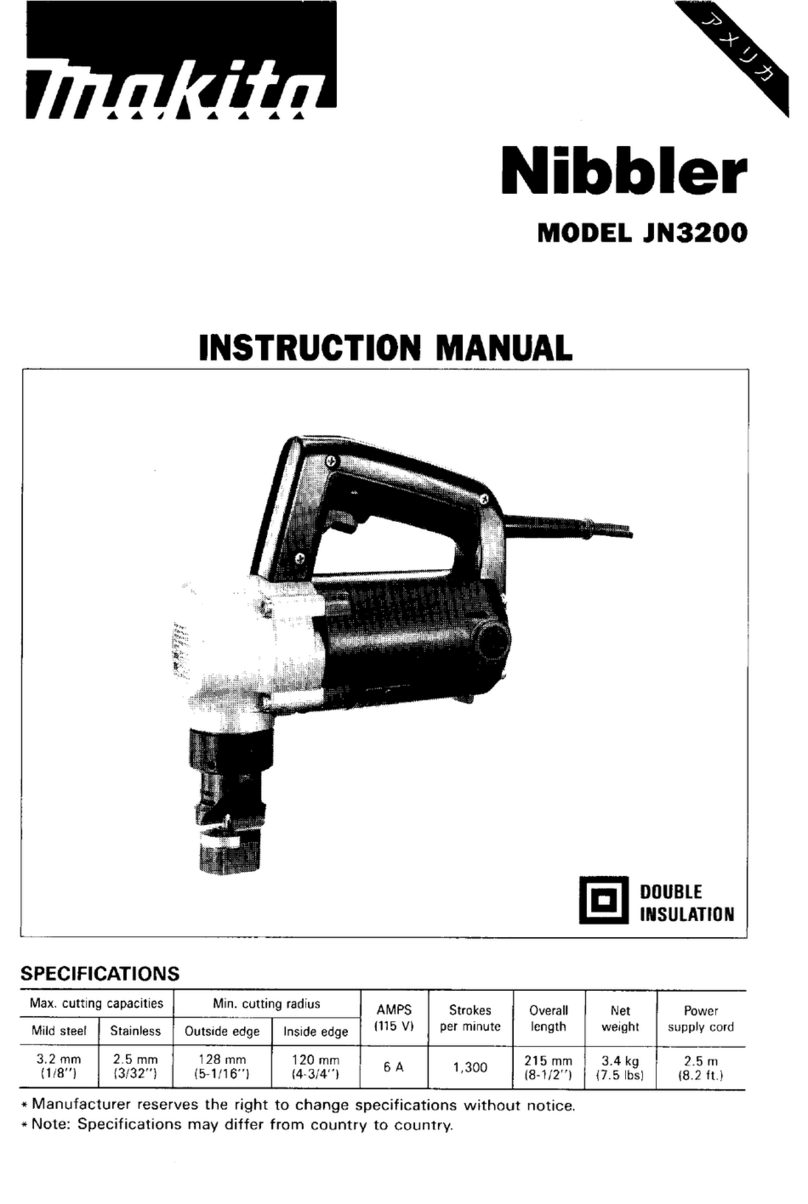

Battery protection system (Lithium-ion

battery with star marking)

Fig.2

Lithium-ion batteries with a star marking are equipped

with a protection system. This system automatically cuts

off power to the tool to extend battery life.

The tool will automatically stop during operation if the tool

and/or battery are placed under one of the following

conditions:

• Overloaded:

The tool is operated in a manner that causes

it to draw an abnormally high current.

In this situation, release the trigger switch on

the tool and stop the application that caused

the tool to become overloaded. Then pull the

trigger switch again to restart.

If the tool does not start, the battery is

overheated. In this situation, let the battery

cool before pulling the trigger switch again.

• Low battery voltage:

The remaining battery capacity is too low and

the tool will not operate. In this situation,

remove and recharge the battery.

Switch action

Fig.3

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the "OFF" position when

released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

Lighting up the front lamp

Fig.4

CAUTION:

• Do not look in the light or see the source of light

directly.

Pull the switch trigger to light up the lamp. The lamp

keeps on lighting while the switch trigger is being pulled.

The light automatically goes out 10 - 15 seconds after the

switch trigger is released.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp.

Be careful not to scratch the lens of lamp, or it may

lower the illumination.

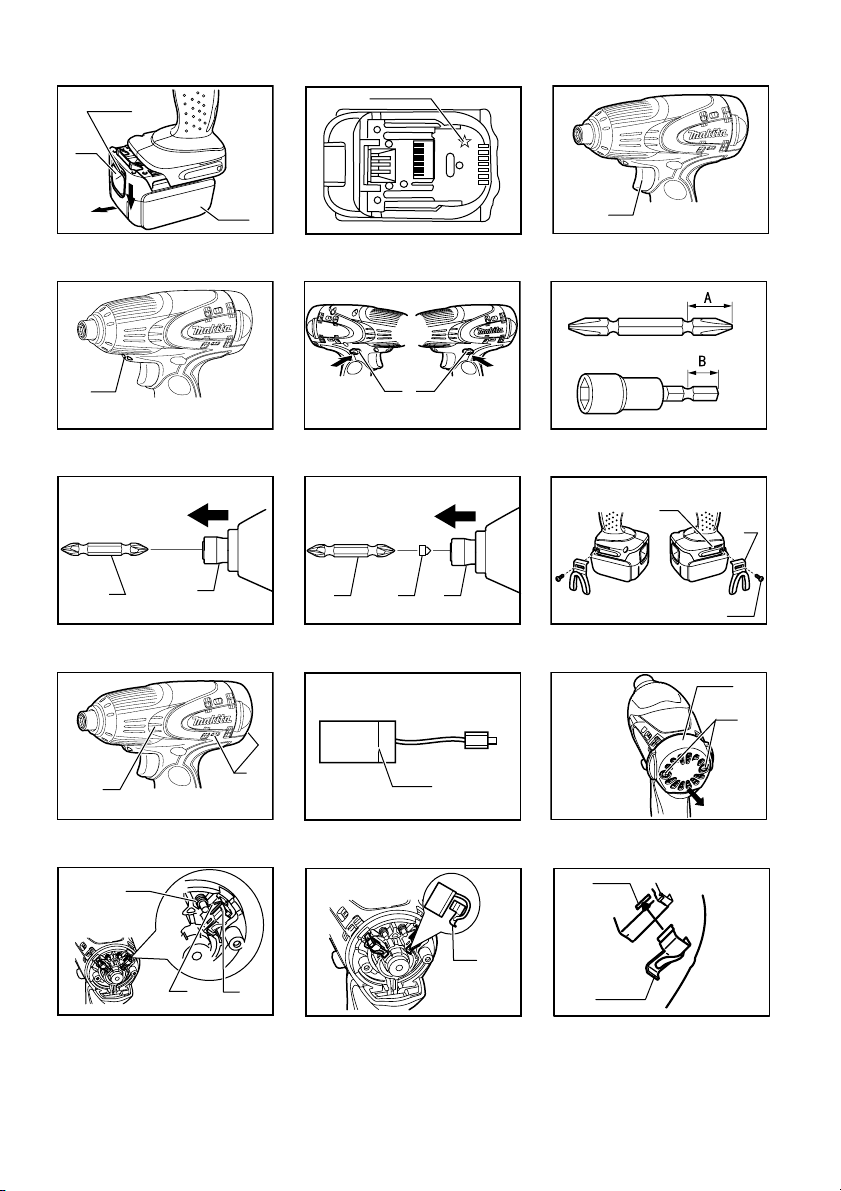

Reversing switch action

Fig.5

This tool has a reversing switch to change the direction of

rotation. Depress the reversing switch lever from the A

side for clockwise rotation or from the B side for

counterclockwise rotation.

When the reversing switch lever is in the neutral position,

the switch trigger cannot be pulled.

CAUTION:

• Always check the direction of rotation before

operation.

• Use the reversing switch only after the tool comes

to a complete stop. Changing the direction of

rotation before the tool stops may damage the tool.

• When not operating the tool, always set the

reversing switch lever to the neutral position.

Characteristics of Cordless Oil-impulse Driver

The Makita Cordless Oil-impulse Driver is a hydraulically

operated impact tool using oil viscosity to produce

impacts. Since oil viscosity changes with the temperature,

be aware of the following two points when operating the

tool.

1. Avoid using the tool below -5 degrees of

temperature. When the tool temperature goes

down below the degrees, this may cause damage

to the motor of tool due to poor impulse.

2. When the tool becomes too hot, it may take longer

to set screws

3. The tool can overheat, causing a failure or hand

burn if you operate it continuously for long hours.

Let the tool cool off for more than 30 minutes

before changing batteries during a long,

continuous job.