71495

rd.

397

-

indianola,

ne

69034

-

phone:

800-382-2607

-

fax:

308-364-2410

-

[email protected] -

.schaffert.com

-

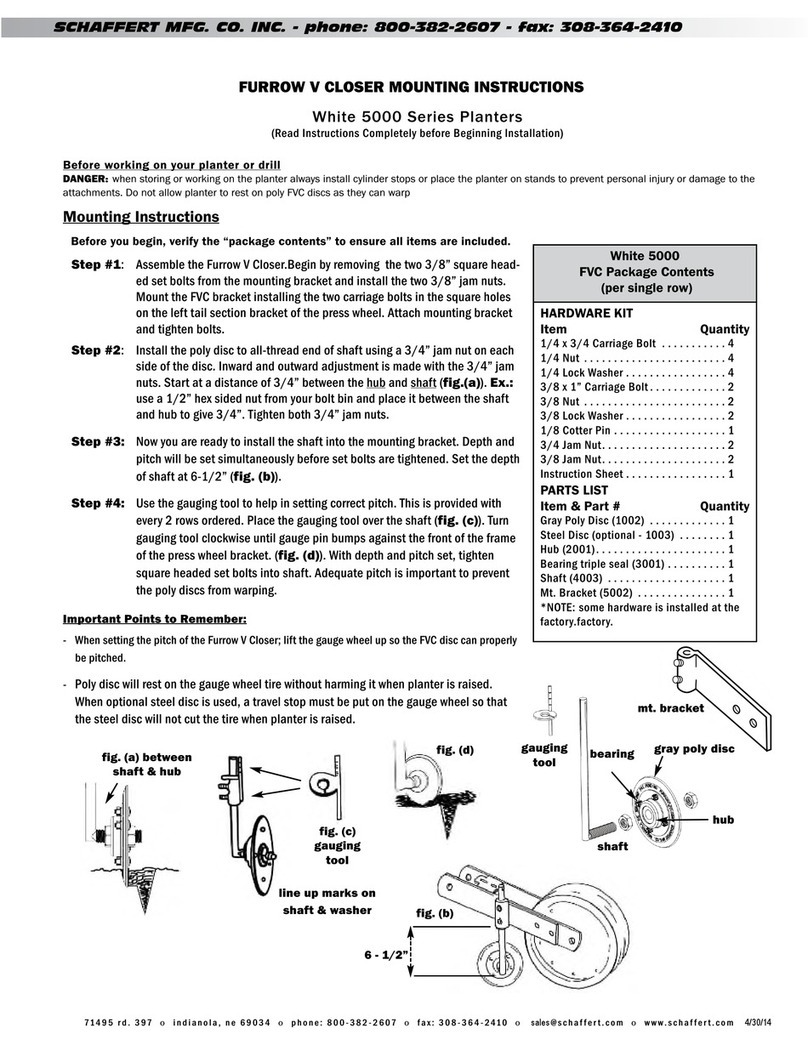

Setp

18,2009

SCHAFFERT MFG. CO. INC. - phone: 8 -382-26 7 - fax: 3 8-364-241

REBO NDERTM MO NTING INSTR CTIONS

Haybu ter Drill

(R ad Instructions Compl t ly b for B ginning Installation)

Before working on your planter or drill

DANGER:wh n storing or working on th plant r always install cylind r stops or plac th plant r on stands to pr v nt p rsonal injury or

damag to th R bound r. WARNING:do not roll back or back up th plant r in or on th ground as this can r sult in damag to th

R bound r.

Mounting In truction

Before you begin, verify all item li ted in the “package content ” table.

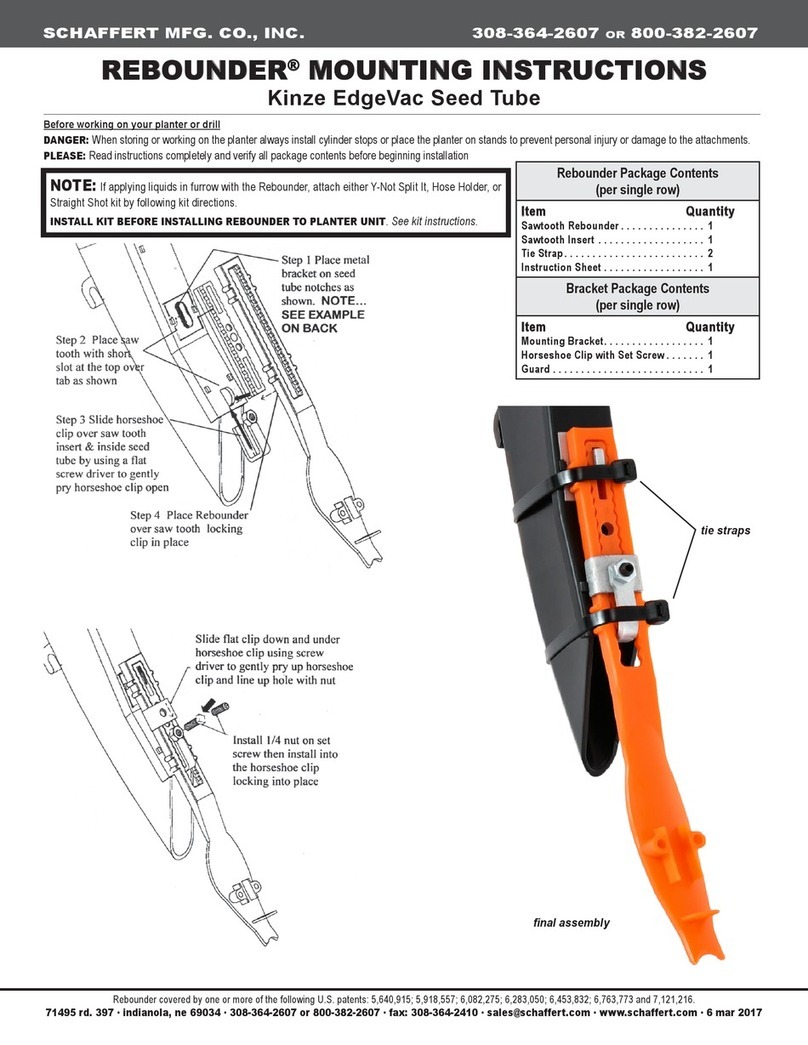

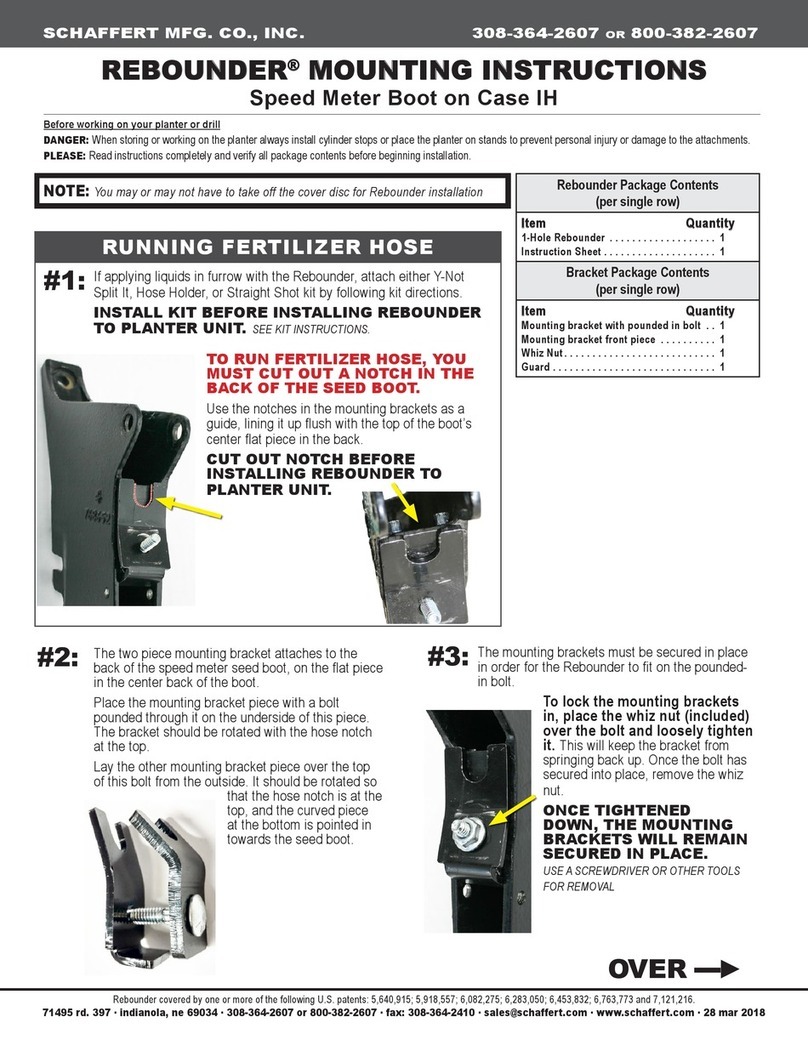

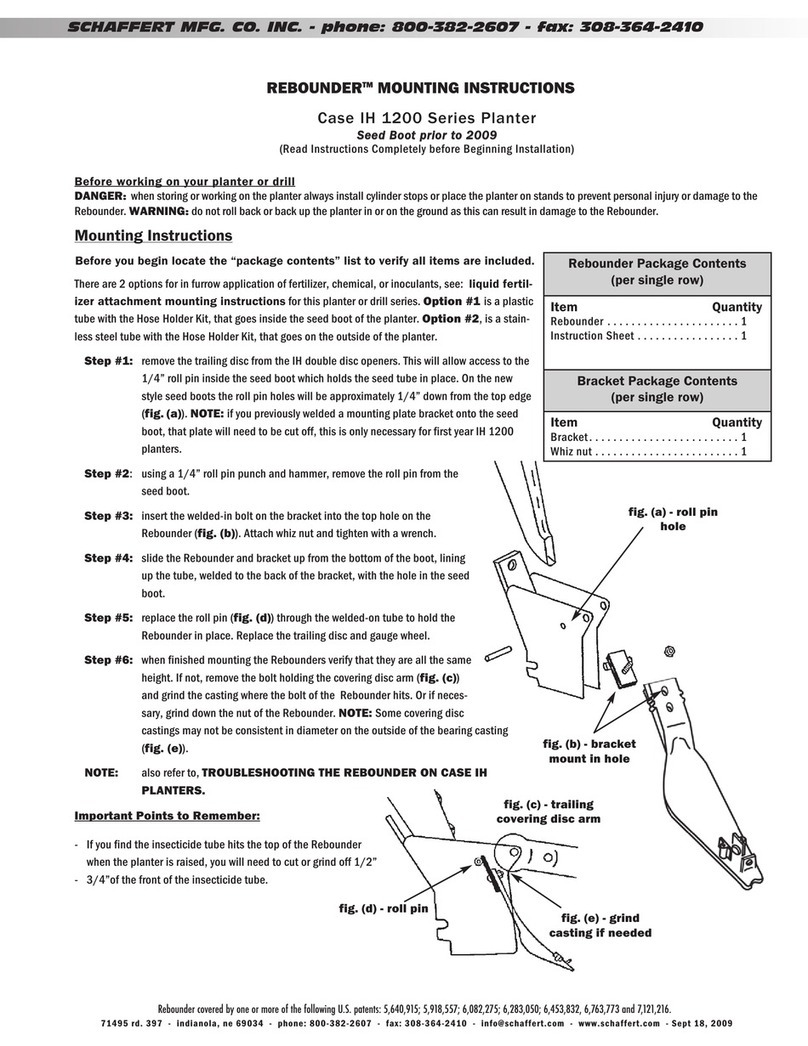

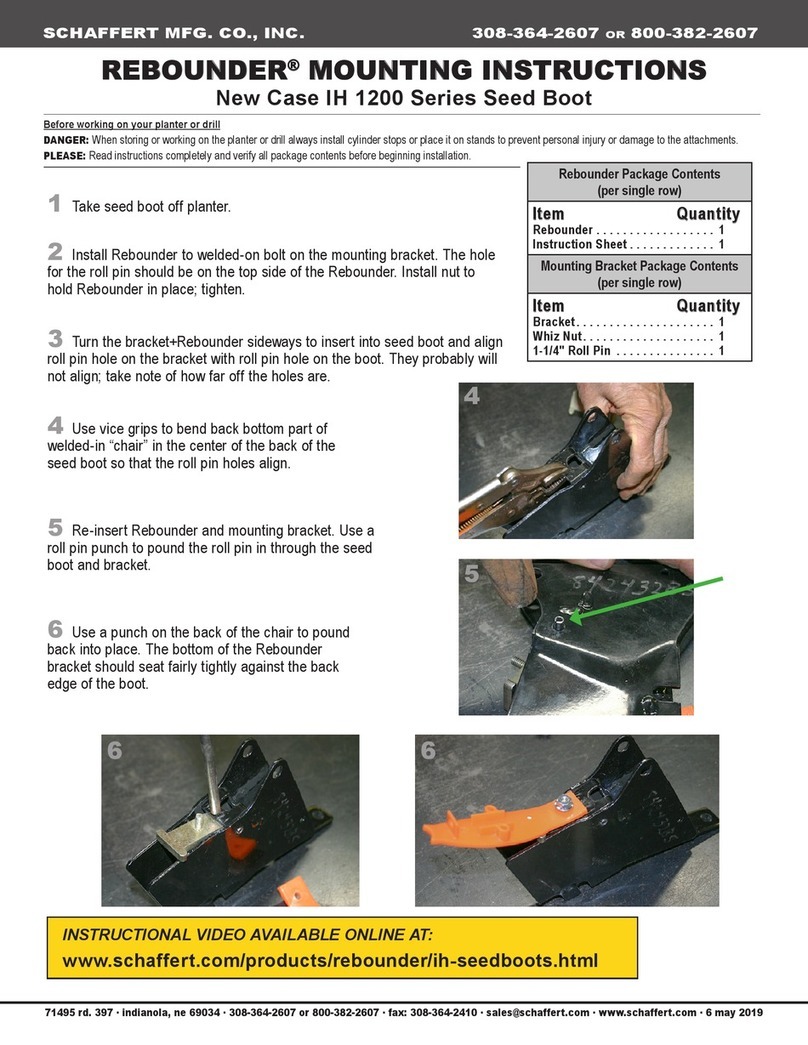

Step #1: b for installing th first R bound r on your drill, r ad th HELPF L

HINTS FOR MO NTING REBO NDERS TO DRILLS on th r v rs sid of

this sh t.

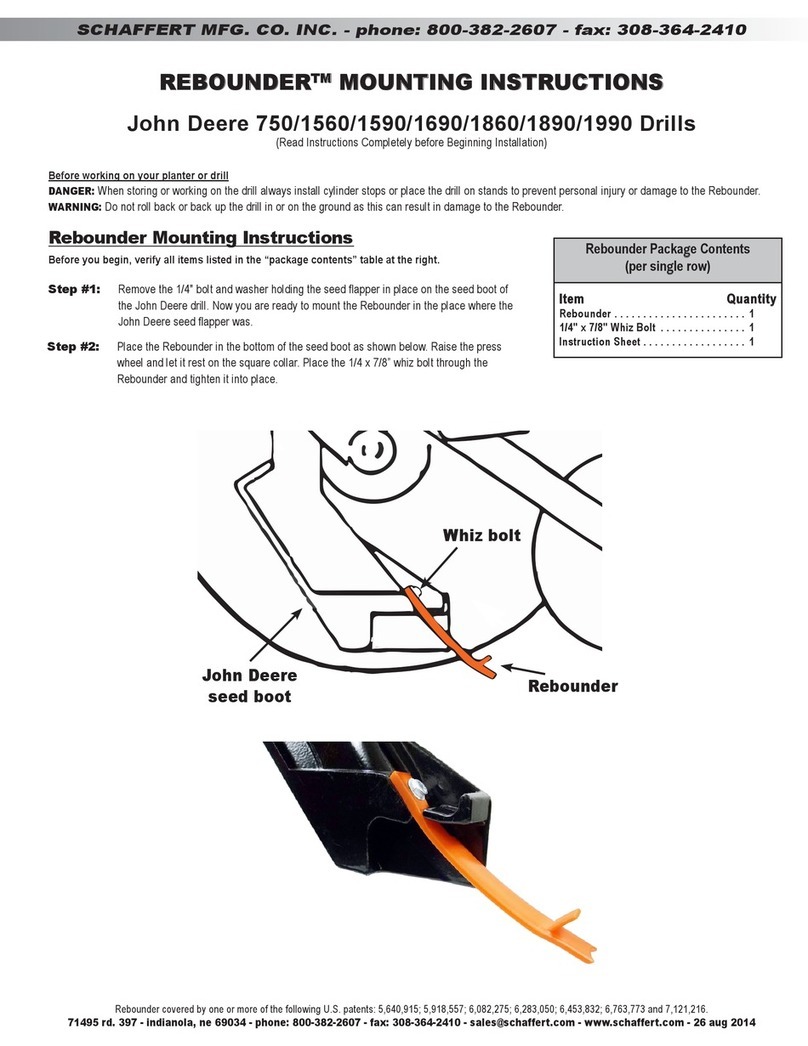

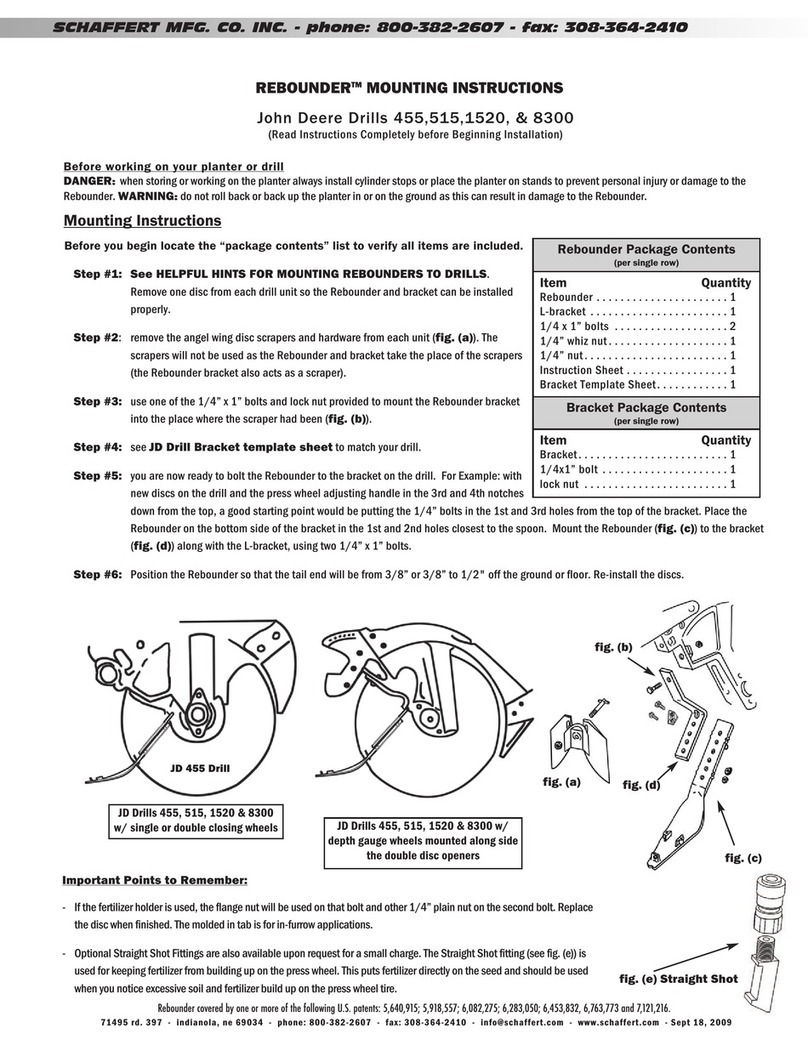

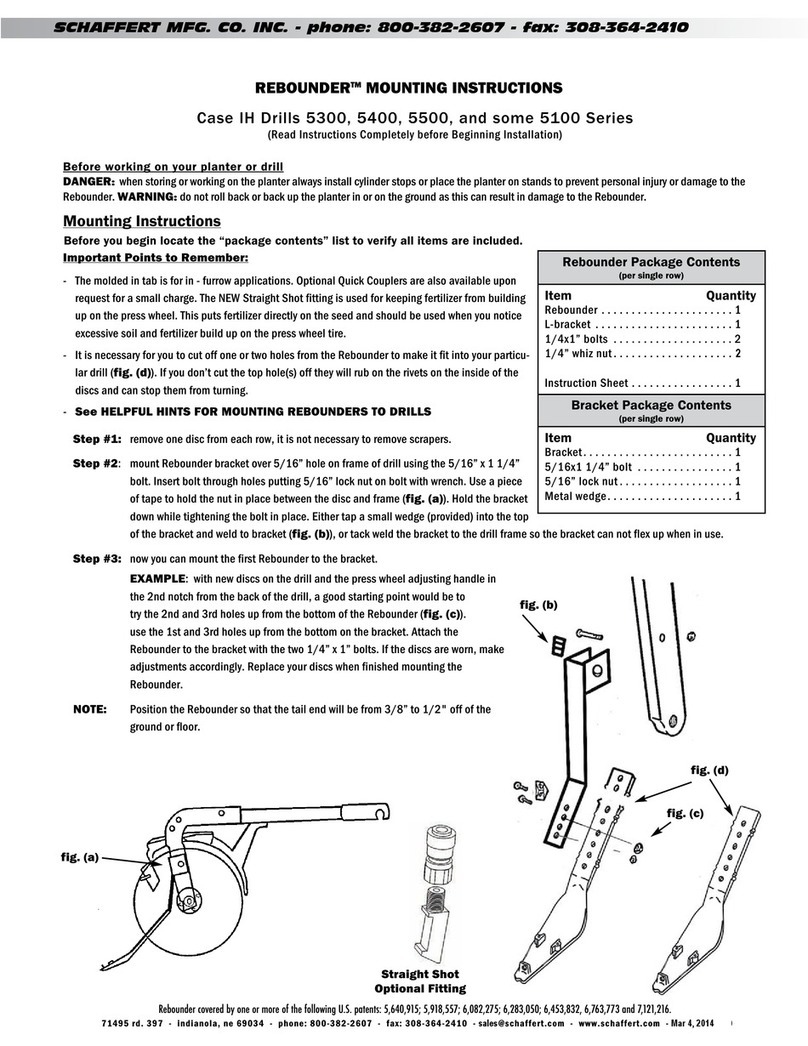

Step #2: r mov on op n r disc from th drill. R mov scrap r nuts and wash rs.

With R bound r brack t in plac , r plac bolt with 5/16” x 1 1/4” bolt pro-

vid d. C nt r R bound r brack t b tw n discs and tight n nut in plac .

Step #3: now you ar r ady to install th R bound r to th brack t. (3 of th 7

hol s hav b n trimm d off th top of th drill R bound r so it will fit th

R bound r brack t on th Haybust r drill.) plac th R bound r on th

bottom sid of th R bound r brack t. Plac th 1//4” x 1” bolts in th

2nd and 3rd hol s of th R bound r (counting up from th bottom of th

R bound r) and ins rt into th 2nd and 4th hol s of th R bound r brack-

t. With this s tting, s t plant r on a flat surfac , th R bound r should b

about 3/8” off th floor or flat surfac . Tight n th nut on th R bound r.

Example Settings: with the new discs on the drill and the press wheel washers set in the middle position (that is, with

approximately 4 washers on the top side), proceed as follows:

Step #4: Plac th L-brack t ov r th top bolt using th 1/4” whiz nut; us th common nut on th oth r bolt. Tight n both bolts

in plac .

Step #5: If discs ar worn, mak adjustm nts accordingly.

Optional fittings are available for fertilizer/chemical applications. Options include, Y-Not Split-It, Hose Holder, or the

Straight Shot, each available for an additional charge.

Rebounder Package Content

(per ingle row)

Item Quantity

R bound r..................1

1/4x1”bolts...............2

L-brack t...................1

WhizNut...................1

1/4”Nut...................1

Instruction Sh t. . . . . . . . . . . . . 1

Bracket Package Content

(per ingle row)

Item Quantity

Brack t....................1

5/16 x 1 1/4” bolt . . . . . . . . . . . 1

5/16”locknut ..............1

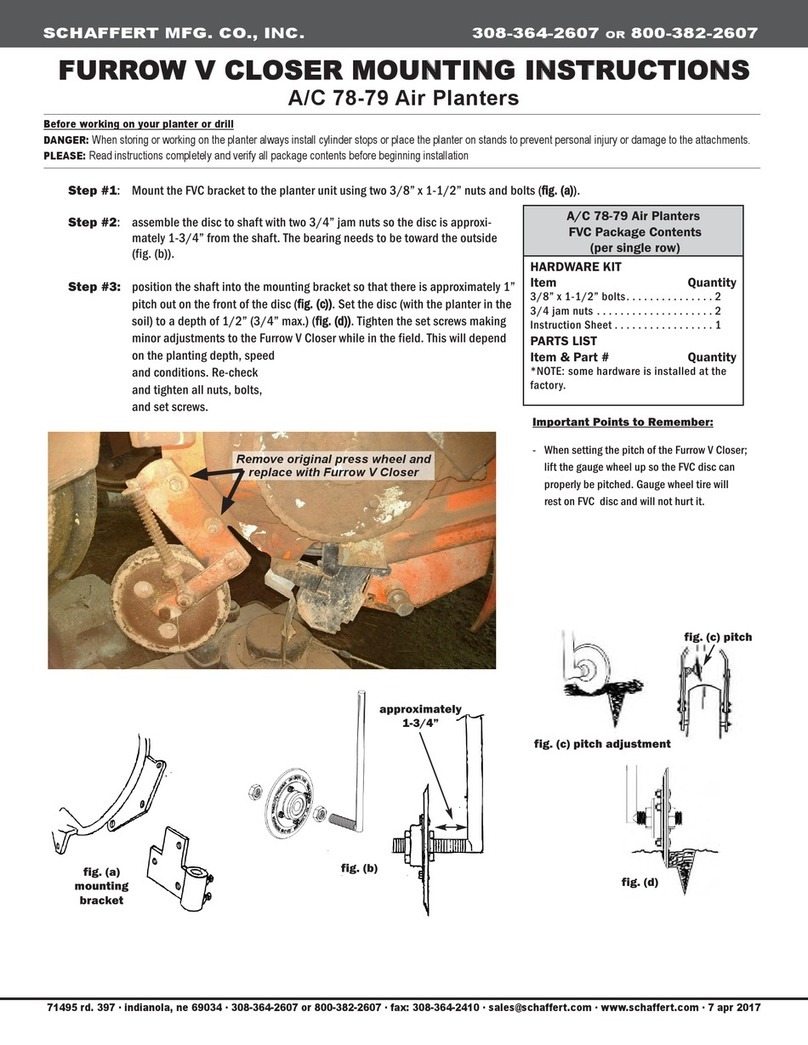

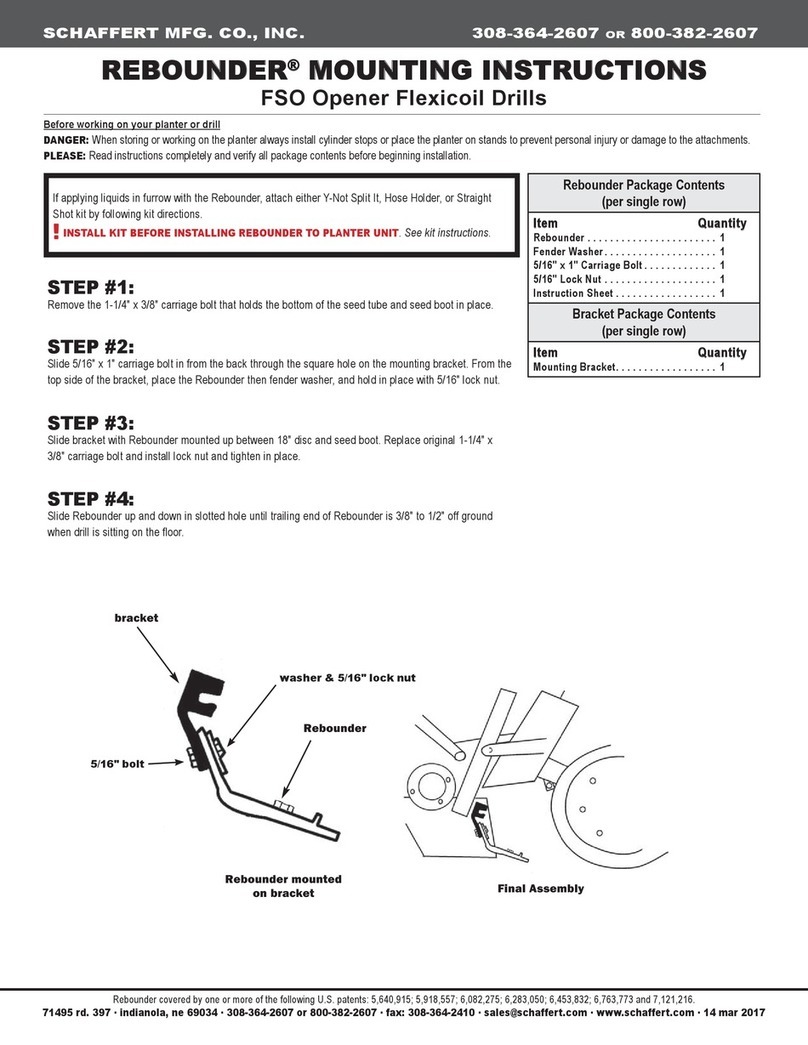

Rebounder, bracket

and components

Rebounder mounted

on bracket Final Assembly

bracket

L-bracket

Rebounder

Rebounder covered by one or more of the following U.S. atents: 5,640,915; 5,918,557; 6,082,275; 6,283,050; 6,453,832, 6,763,773 and 7,121,216.