Page: 4 of 35

☆Mini flathead screwdriver

☆

Side cutter

☆

Tape-wrapped flathead screwdriver

☆

Ratchet

☆

10mm socket

☆

Mini Scissors

☆Trim clip remover/tack puller ☆Nylon trim remover

☆Small metal scale ruler

☆Electrical tape

☆90 degree needle nose pliers

☆Small utility knife

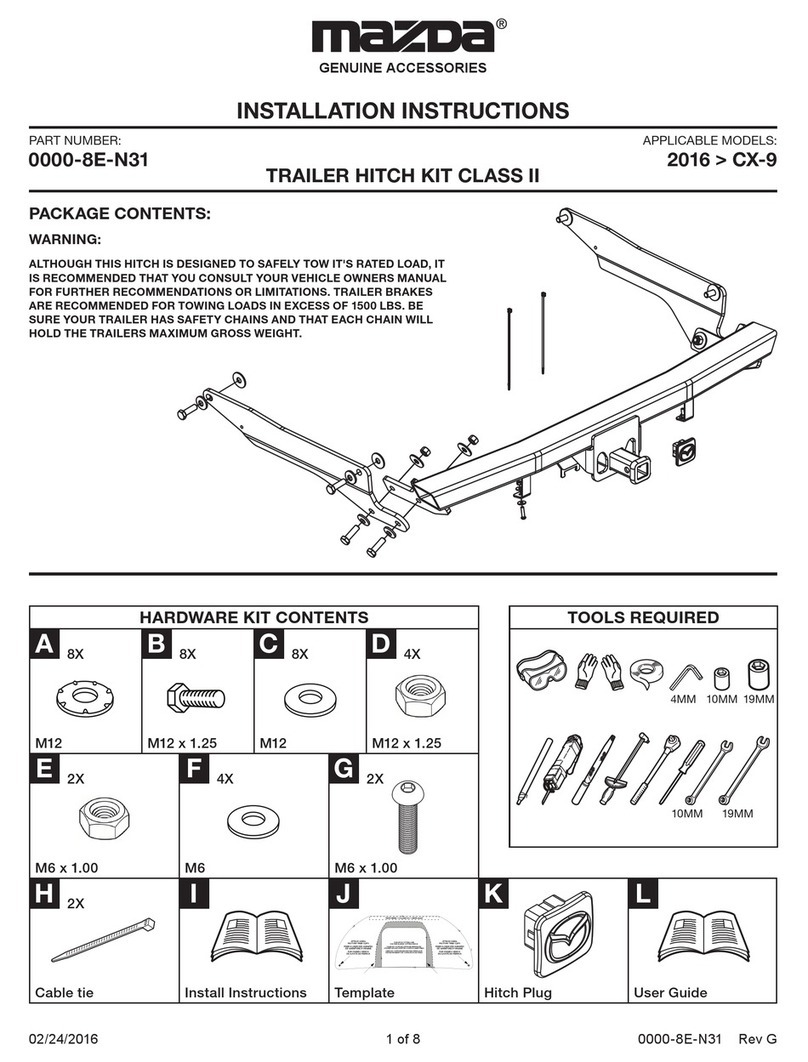

REQUIRED TOOLS

OTHER PREPARATIONS

☆Soft clean cloth

☆Protective mat

☆Protective masking

tape

☆Protective

gloves

☆IPA (Isopropyl alcohol)

WARNING

When the negative battery is

connected during operation,

may cause electric shock

or other personal injuries.

Disconnect the negative cable

before

installation.

Before performing any work,

park the vehicle on level

ground, apply the parking

brake securely, and then block

the wheels.

Be careful when handling

drills and other sharp objects.

If not handled properly, it

could result in serious injury.

When connecting/dis-

connecting connectors,

grasp

the connectors, not the

wires.

Otherwise a short,

and an

accident from poor

contact or

fire may occur.

Make sure the connector is

securely pressed in until a click

sound is heard.

Otherwise, a fire or other

accident may occur due to an

open circuit or poor contact.

Secure the harness with the

band (part included) so it

doesn’t dangle. If not, it may

cause a short, accident, or

fire.

Do not pull the harness with

excessive force. Doing so can

cause a breakage or a short-

related accident, as well as an

electrical short or fire.

!

CAUTION

Using improper tools may

cause damage and/or broken

parts. Use the correct tool for

the job.

Wrap protective tape around

screwdrivers and fastener

remover tools to prevent

scratching the vehicle.

Excessive length of tie wrap may

interfere with other parts and

cause damage.

Put the removed parts and

the parts in the kit on the

protective sheet to prevent

scratches.

When the negative battery

cable is removed, the

initial value or

memory for

the power windows,

clock,

i-stop, steering angle

sensor reference point will

be cleared. Perform re-

initialization.

If there is dust, dirt or grease

on the adhesion surface,

the adhesive strength of the

double- sided adhesive tape

will splotch and adhesive

power of the tape will be

reduced. Wash and degrease

the surface of the adhesion

area before applying the

double-sided adhesive tape.

Be sure to wash interior

and exterior parts using IPA

(isopropyl alcohol).

If tape or a mount base is re-

adhered, the adhesive strength

will be weakened.

Before adhering, accurately

determine the adhesion

position.

To assure sucient adhesiveness

of the double-sided adhesive

tape, press the adhesive

surface of the tape to the

adhesion surface evenly. In

particular, press suciently at

the ends of the double-sided

adhesive tape where the

adhesion surface is curved.

·

To perform the installation work safely and maintain functionality and quality, thoroughly read these instructions before

performing the procedures and always heed the warnings and precautions.

·

In the work procedures, there are descriptions which are only indicated in the figure. Make sure to follow these procedures

as well.

ADVICE

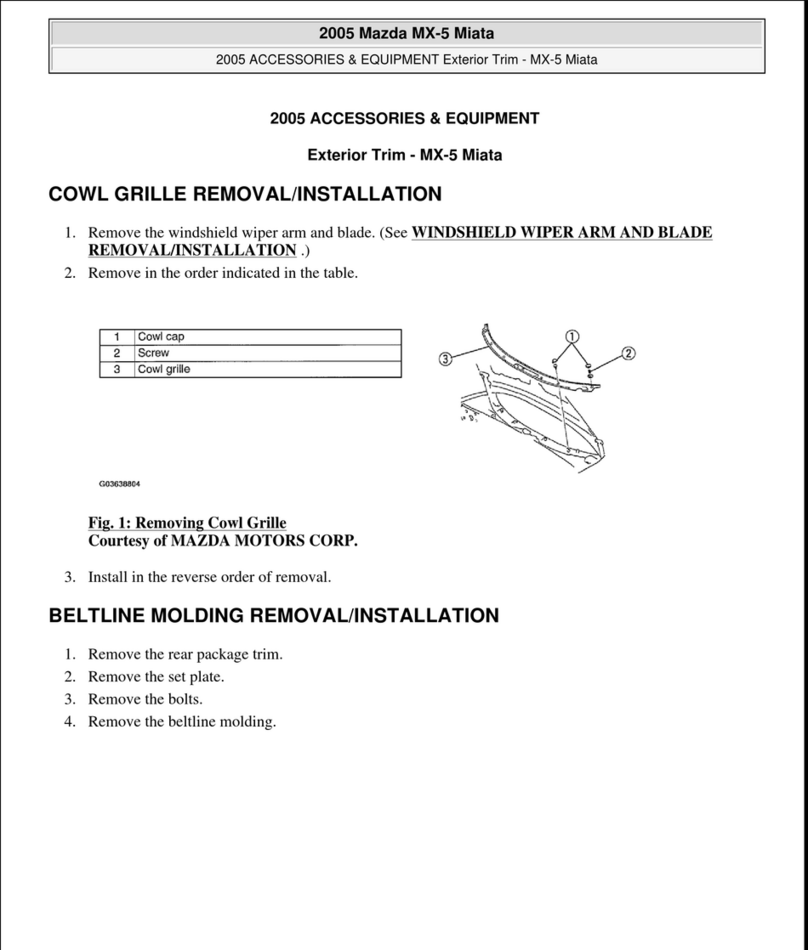

Refer to the Workshop Manual

for removal and installation of

vehicle parts.

3. BEFORE INSTALLATION

!