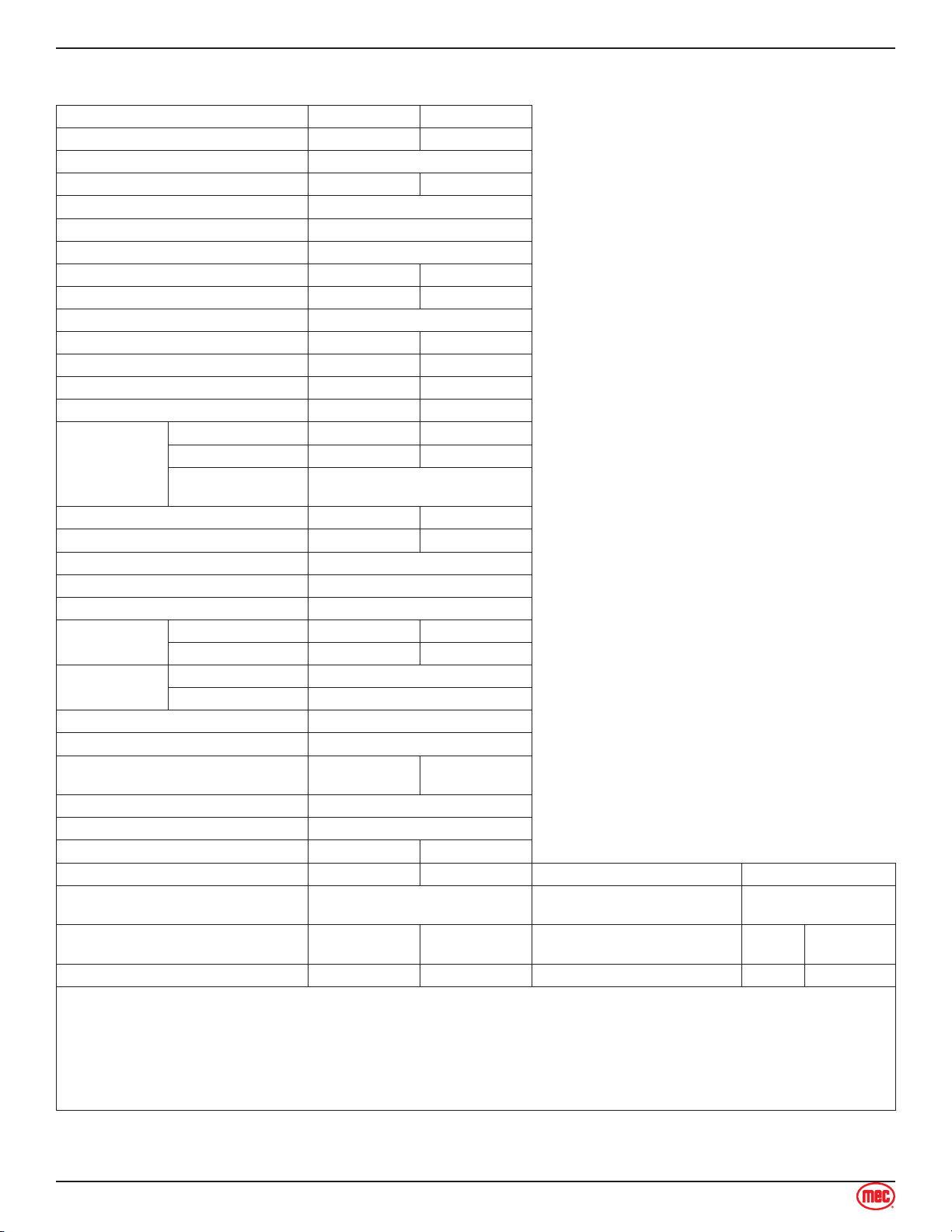

Page v 34-J Diesel - Service & Parts Manual

December 2021

Jib Cylinder Assembly . . . . . . . . . . . . . . . . . . 180

Level Cylinder Assembly . . . . . . . . . . . . . . . . . 182

Axle Lock Cylinder. . . . . . . . . . . . . . . . . . . 184

Fuel Tank Assembly . . . . . . . . . . . . . . . . . . 186

Boom Hose Routing, Interior . . . . . . . . . . . . . . . . 188

Boom Hose Routing, Exterior . . . . . . . . . . . . . . . . 190

Chassis Hose Routing, Top View . . . . . . . . . . . . . . . 192

Chassis Hose Routing, Bottom View . . . . . . . . . . . . . . 194

Chassis to Turret Hose Routing, Side View . . . . . . . . . . . . 196

Turret Hose Routing, Engine Side Only . . . . . . . . . . . . . 198

Turret Hose Routing, Engine to Interior . . . . . . . . . . . . . 200

Turret Hose Routing, Engine to Controls . . . . . . . . . . . . . 202

Turret Hose Routing, Interior View. . . . . . . . . . . . . . . 204

Turret Hose Routing, Control Side. . . . . . . . . . . . . . . 206

Section 26 - Base . . . . . . . . . . . . . . . . . 208

Chassis Assembly, Part 1 . . . . . . . . . . . . . . . . . 208

Chassis Assembly, Part 2 . . . . . . . . . . . . . . . . . 210

Chassis Assembly, Part 3 . . . . . . . . . . . . . . . . . 212

Engine Hood Assembly . . . . . . . . . . . . . . . . . 214

Engine Side, Hood Stop Assembly . . . . . . . . . . . . . . 216

Control Hood Assembly . . . . . . . . . . . . . . . . . 218

Control Side, Hood Stop Assembly . . . . . . . . . . . . . . 220

D1105 Engine Kit . . . . . . . . . . . . . . . . . . . 222

Exhaust Assembly . . . . . . . . . . . . . . . . . . . 230

Turret Assembly, Part 1 . . . . . . . . . . . . . . . . . 232

Turret Assembly, Part 2 . . . . . . . . . . . . . . . . . 234

Turret Assembly, Part 3 . . . . . . . . . . . . . . . . . 236

Turret Assembly, Part 4 . . . . . . . . . . . . . . . . . 238

Section 27 - Options. . . . . . . . . . . . . . . . . 240

Option, Cold Weather . . . . . . . . . . . . . . . . . . 240

Option, 3.5kW Generator . . . . . . . . . . . . . . . . . 242

Option, 3.5kW Generator Manifold Assembly . . . . . . . . . . . . 246

Option, Upper Control Box Cover . . . . . . . . . . . . . . . 248

Option, 7.5kW Generator Assembly . . . . . . . . . . . . . . 250

Option - 7.5kW Breaker Box . . . . . . . . . . . . . . . . 252

Option - Subassembly, 7.5kW Outlet Boxes MkII . . . . . . . . . . . 254

Option - 7.5kW Generator Manifold Assembly . . . . . . . . . . . 256

Option - Proactive Platform Safety System . . . . . . . . . . . . 258

Section 28 - Decals . . . . . . . . . . . . . . . . . 260

Decals...................... 260