QUICKGUIDE RALLY MIG 161i

UK

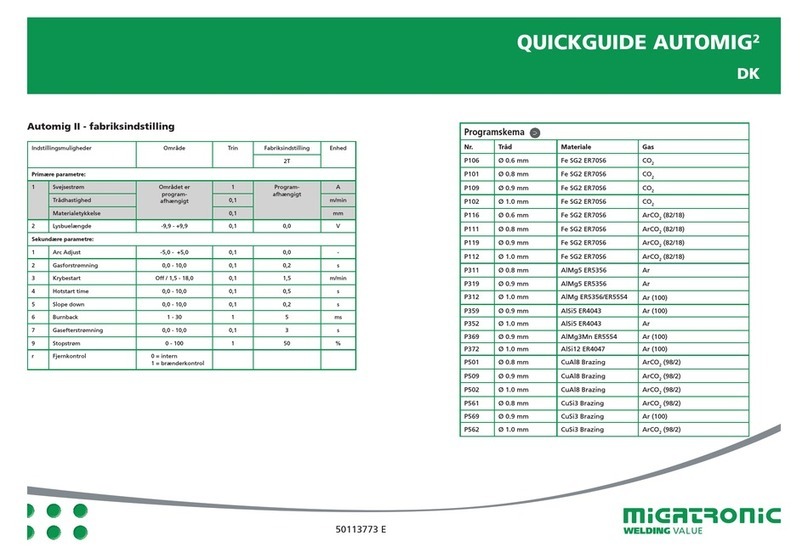

Selection of AlMg/AlSi programs:

1. Select material the material type “Al”

2. Select material type 0.9 or 1.0mm

3. Keep the material key pressed for 5sec

until the “Al” LED is switched off as

indication of entrance to set-up mode.

The display shows

319 (0.9 mm AlMg ER5356),

359 (0.9 mm AlSi5 ER4043) or

369 (0.9 mm AlMg3Mn ER5554)

if 0.9 mm wire has been selected, or

312 (1.0 mm AlMg ER5356/ER5554),

352 (1.0 mm AlSi5 ER4043) or

372 (1.0 mm AlSi12 ER4047)

if 1.0mm wire has been selected.

4. Turn the control knob back and forth

until the correct program is displayed.

5. The program is selected by one more

press on the material key knob, and the

machine will return to normal mode.

Selection of CuAl/CuSi programs:

1. Select material the material type “Cu”

2. Select material type 0.8, 0.9 or 1.0mm

3. Keep the material key pressed for 5sec

until the “Cu” LED is switched off as

indication of entrance to set-up mode.

The display shows

501 (0,8 mm CuAl8 Brazing) or

561 (0,8 mm Cusi3 Brazing)

if 0,8 mm wire has been selected, or

509 (0,9 mm CuAl8 Brazing) or

569 (0,9 mm CuSi3 Brazing)

if 0,9 mm wire has been selected, or

502 (1,0 mm CuAl8 Brazing) or

562 (1,0 mm CuSi3 Brazing)

if 1,0 mm wire has been selected.

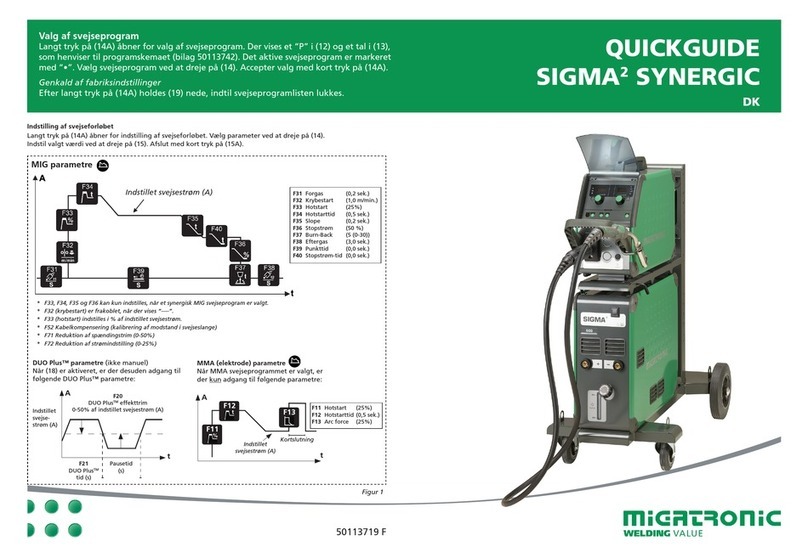

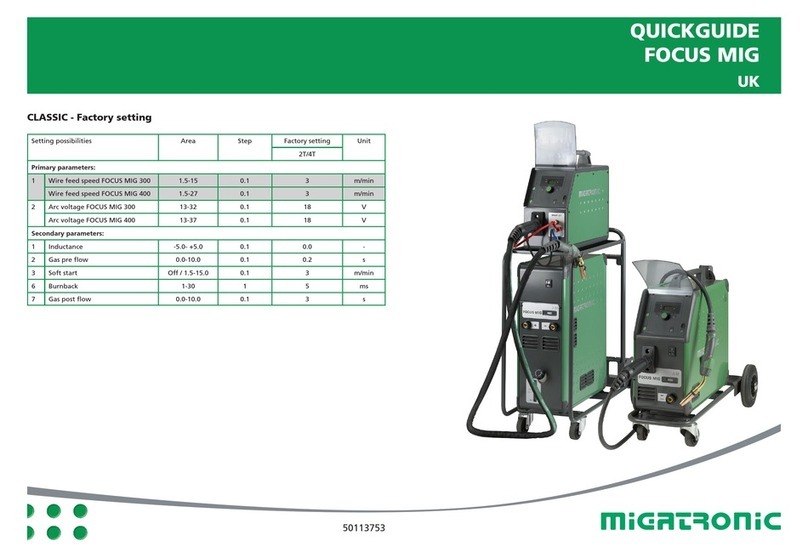

1 Selecting welding process MIG/MMA

Selecting welding process TIG under

secondary MMA parameters.

2 Selecting type of material

Press the key until the LED is lit at the

relevant material.

3 Selecting wire diameter

Press the key until the LED is lit at the

relevant wire diameter.

7 Secondary parameters

Press the key until the desired parameter is

shown on the display.

Press key 4briefly to finish.

AWelding voltage

B Warning – overheating

RALLY MIG 161i CONTROL PANEL

I. Switch on the machine select process

II. Select type of material and

wire diameter

III. Set one of the following parameters:

welding current, wire feed speed or

thickness of material

IV. Trim the arc length, if required

5

B

1

A

4

2

6

3 7

4. Turn the control knob back and forth

until the correct program is displayed.

5. The program is selected by one more

press on the material key knob, and the

machine will return to normal mode.

Reset function

Press and hold the key for 5 seconds. Flashing

LED indicates that the relevant program is

reset to factory settings.

4 Primary parameters

Set one of the following interdependent

primary parameters at your own option:

welding current, wire feed speed or thickness

of material.

Inching

Wire inching starts by pressing the green key

pad and simultaneously triggering the torch

trigger. Wire inching continues even though

the green key pad has been released. It does

not stop until the torch trigger has been

released again

5 Arc length

The arc length can be adjusted as required.

Press the key under the symbol and turn the

control knob: plus (+) for a longer arc and

minus (-) for a shorter arc (-9.9 to +9.9).

6 Control knob

Adjustment of welding current, wire feed

speed, thickness of material or arc length.

Inching speed is adjustable during wire

inching. If the key for secondary parameters

is active, it is possible to trim the secondary

parameters.