- 1 -

MINGDA TECHNOLOGY CO.,LTD

www.md-3d.com

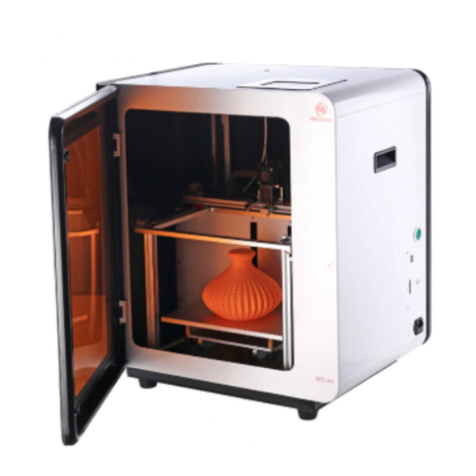

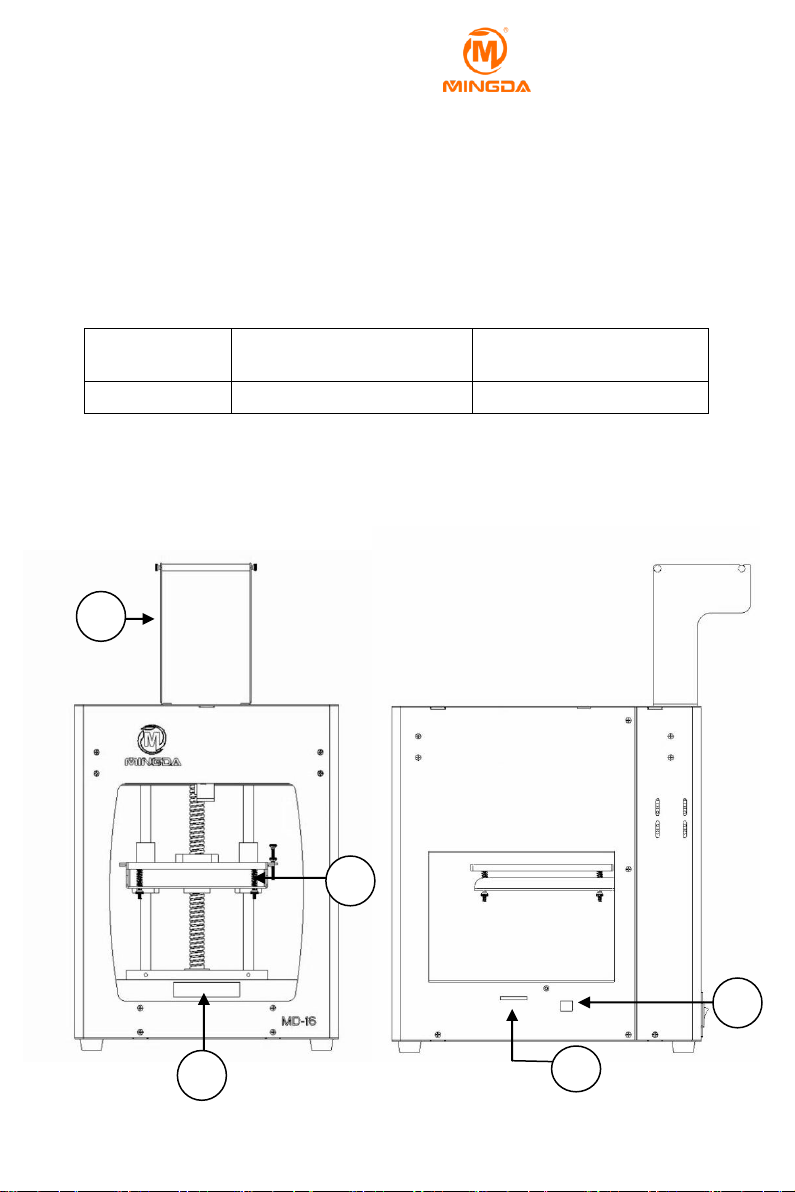

1 Brief Introduction

MD Series Industrial 3D Printers adhere to the design concept of the

simple to the extreme. It can print product quickly and easily, even if

you've never used a 3D Printer.

The printer prints the model with PLA or ABS, so the products will

be strong and durable. You can make drilling, tapping, grinding and

painting on the PLA or ABS models. MD Series 3D Printers combine

proprietary hardware, software and filaments technologies creatively.

Welcome to a new world of 3D printing!

User-Guide Instructions

This User Guide has been carefully organized into "Installation",

"Operation", "Maintenance" and "Troubleshooting" sections for client to

read and understand. Be sure to read the sections carefully to get the

best use of your 3D printer.

Learn More Information

SD card provides the electronic user guide. This guide provides

information as following topics:

1. troubleshooting information

2. important safety statements and regulatory information

3. Printing supplies related information

4. Detailed instructions for use

You can also find more information on the official website.

http://www.md-3d.com http://www.3dMINGDA.com

Safety Precautions

The following precautions ensure that the customer uses the printer

correctly and protects the printer from damage. Please always follow

these precautions.

1. Use the specified power supply voltage. Do not connect multiple

devices to the printer's power outlet to avoid overload.

2. Make sure the printer is properly grounded, Or it may cause

electric shock, fire or electromagnetic interference.

3. Contact your after-sales or local service before disassembling or

repairing the printer by yourself. Check the "Support" section in the User

Guide.

4. It is recommended to use the power cord that came with the