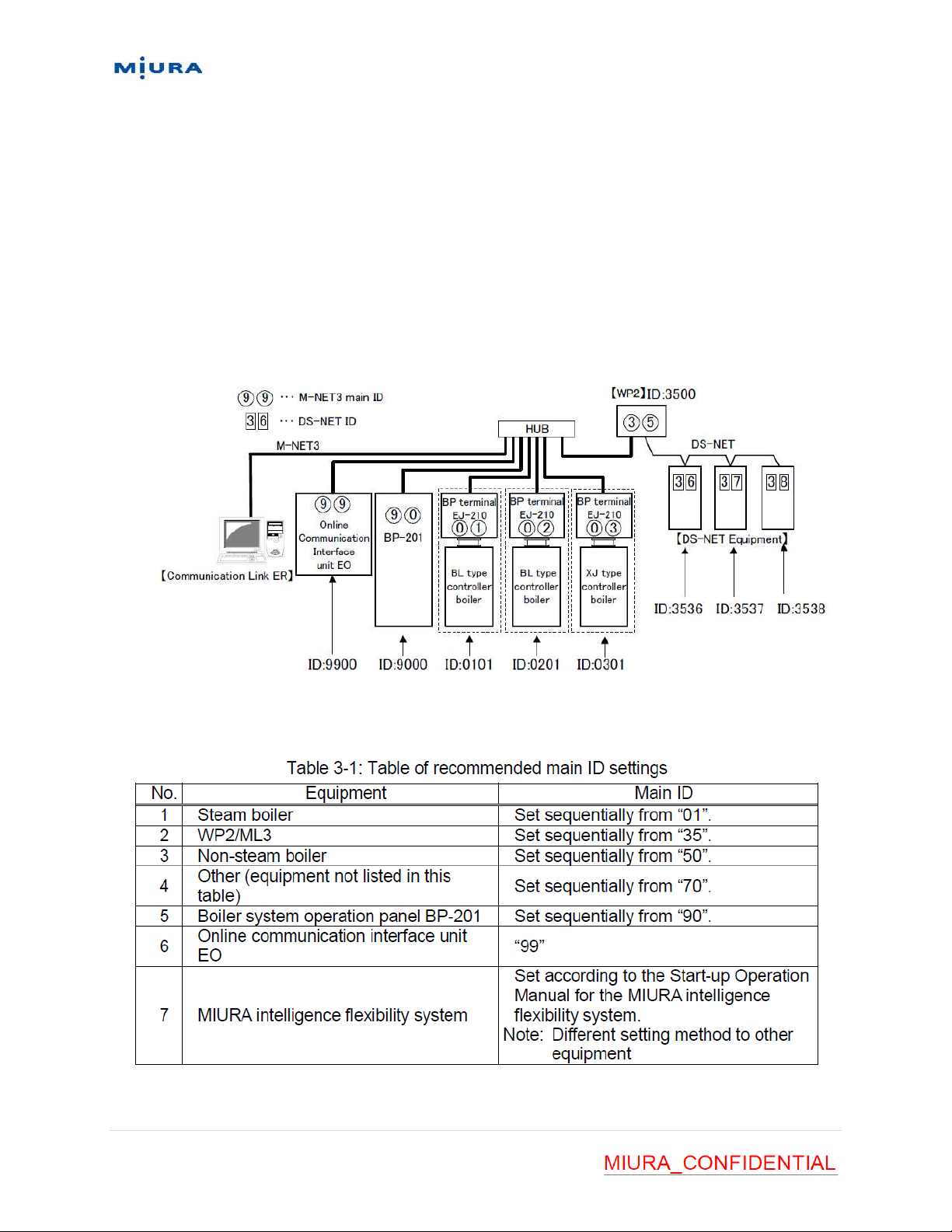

Miura BP-201 Troubleshooting guide

Other Miura Boiler Supplies manuals

Miura

Miura MP1-200 User manual

Miura

Miura WP2-200A User manual

Miura

Miura CONNECT User manual

Miura

Miura BP-201 User manual

Miura

Miura EJ-210 User manual

Miura

Miura WP2-200A User manual

Miura

Miura CMU-324HE User manual

Miura

Miura CMU-324HE User manual

Miura

Miura STEAM EO-010A User manual

Miura

Miura Comm-Link User manual

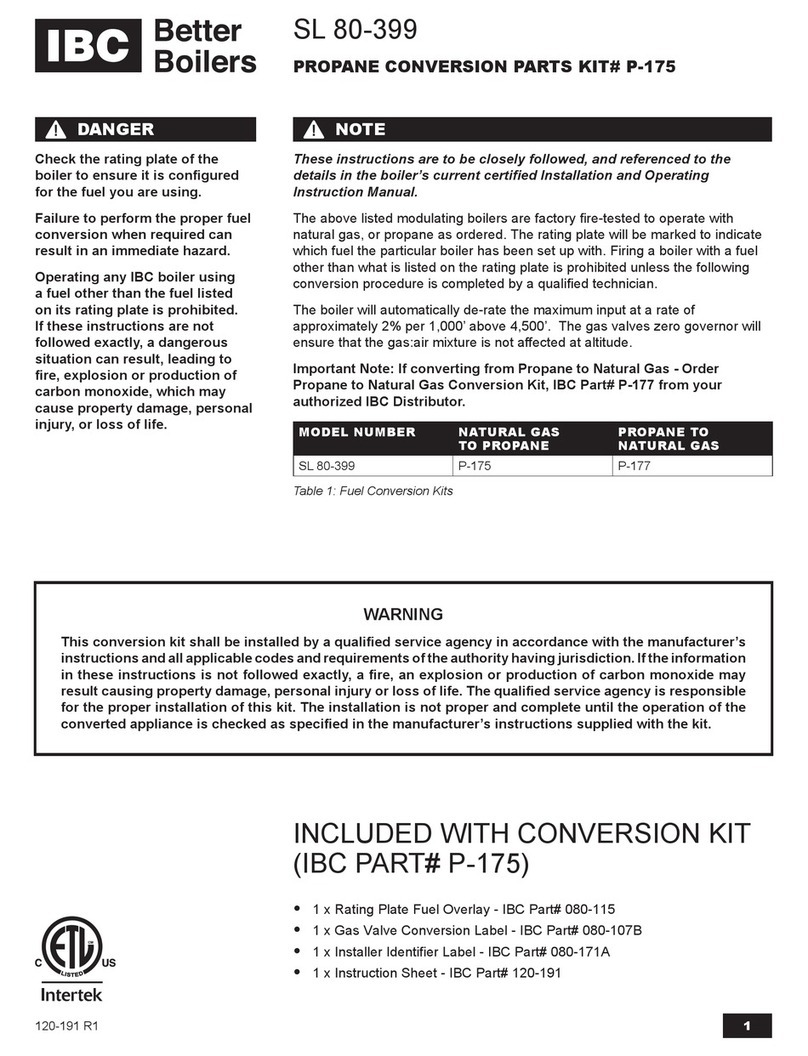

Popular Boiler Supplies manuals by other brands

TriangleTube

TriangleTube PSRKIT84 manual

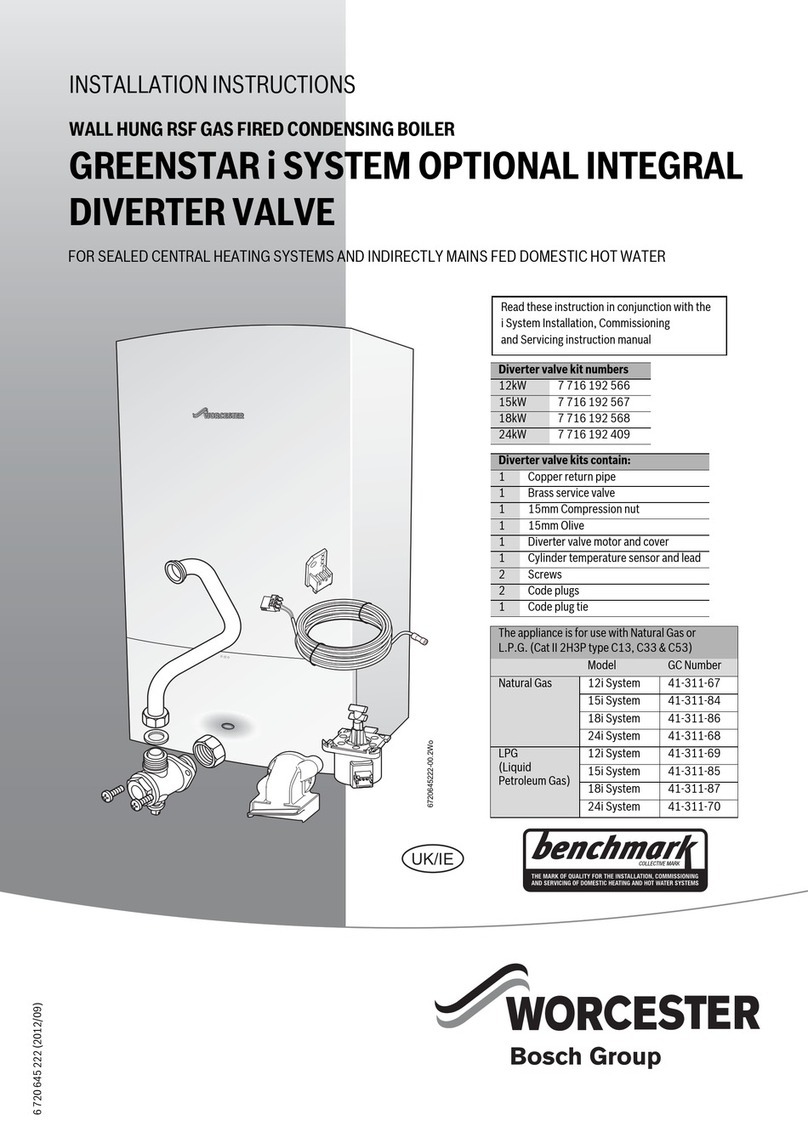

Bosch

Bosch Worcester installation instructions

TriangleTube

TriangleTube PSRKIT36 instructions

De Dietrich Thermique

De Dietrich Thermique AD252 Assembly instructions

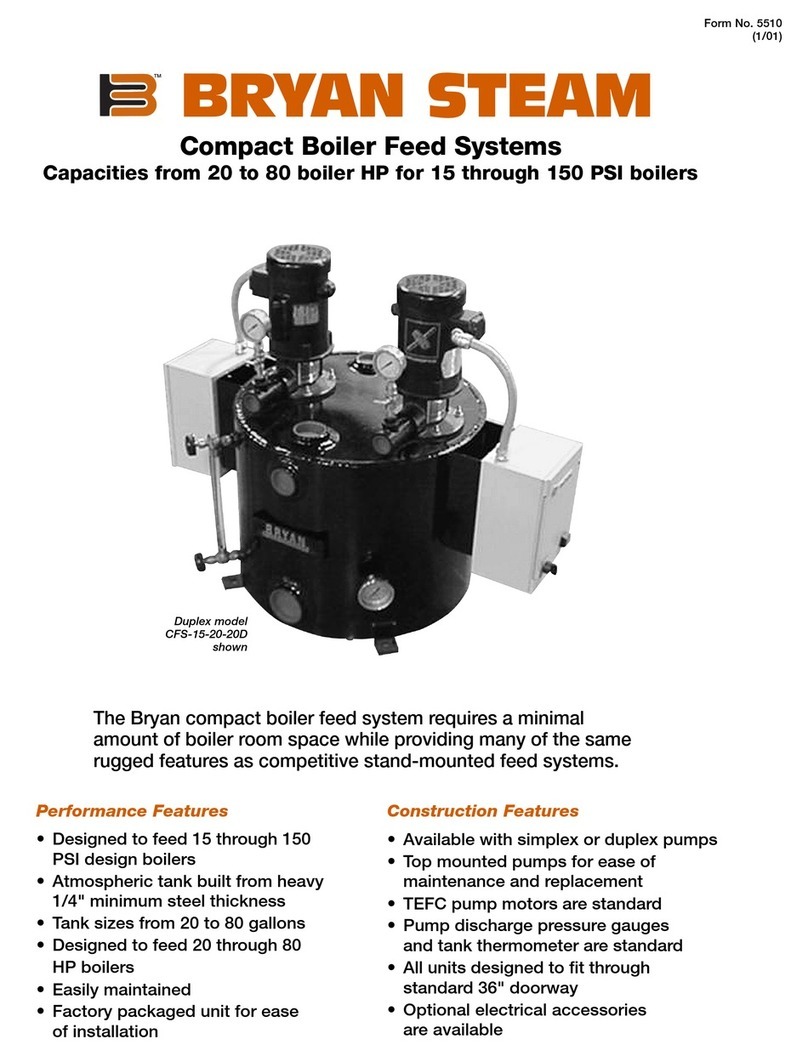

Bryan Boilers

Bryan Boilers CFS-15-20-20D Specification sheet

REMEHA

REMEHA Celcia MC4 Installation and user manual