Table of Contents

Introduction.................................................................................................................. i

1. Precautions Regarding Installation .................................................................... 1

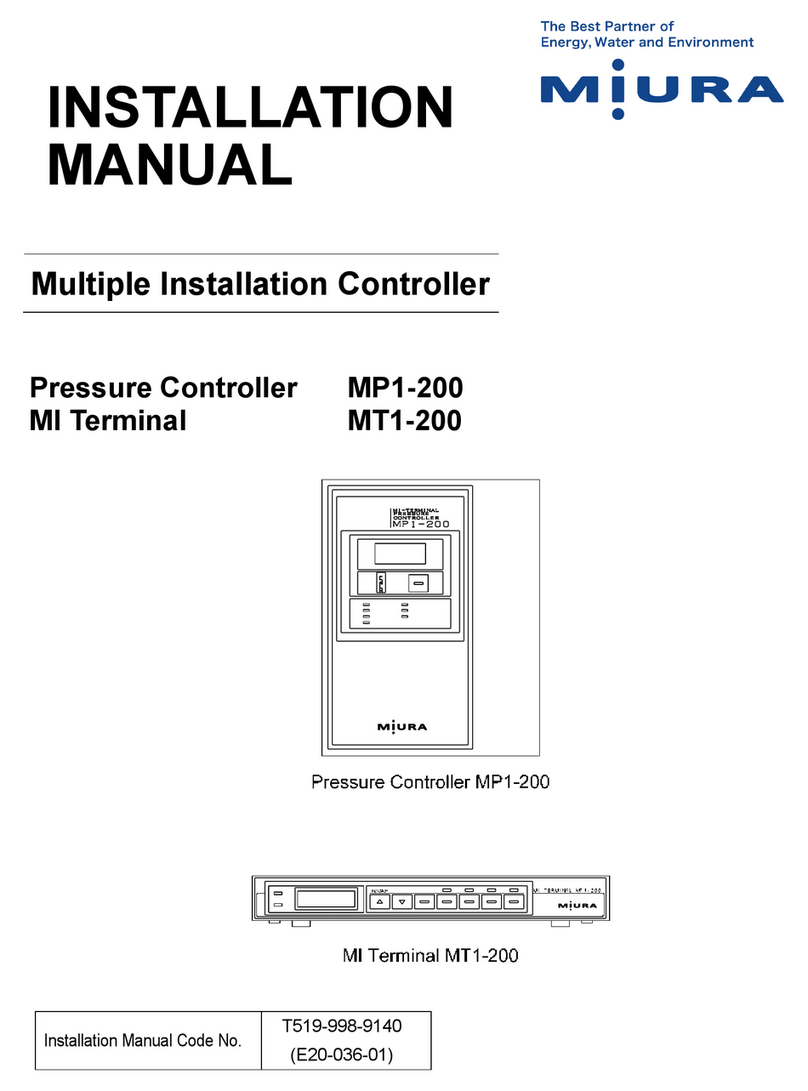

2. Overall Dimensions .............................................................................................. 2

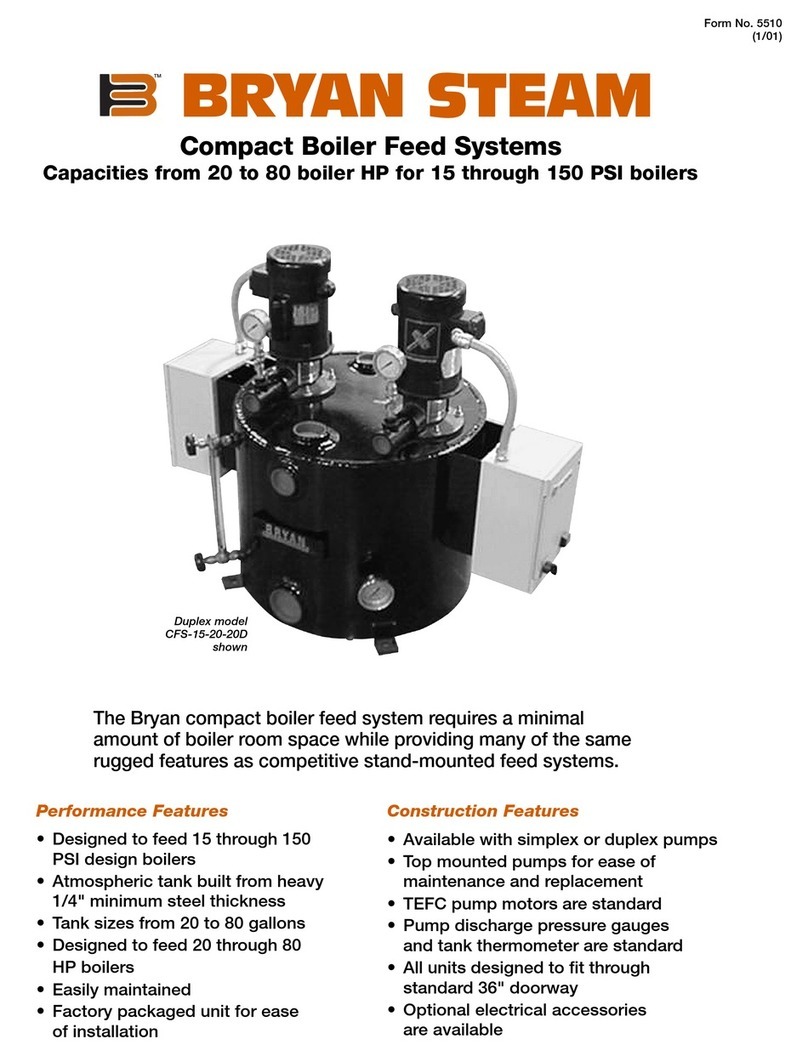

2.1 BP-201STA ........................................................................................................................... 2

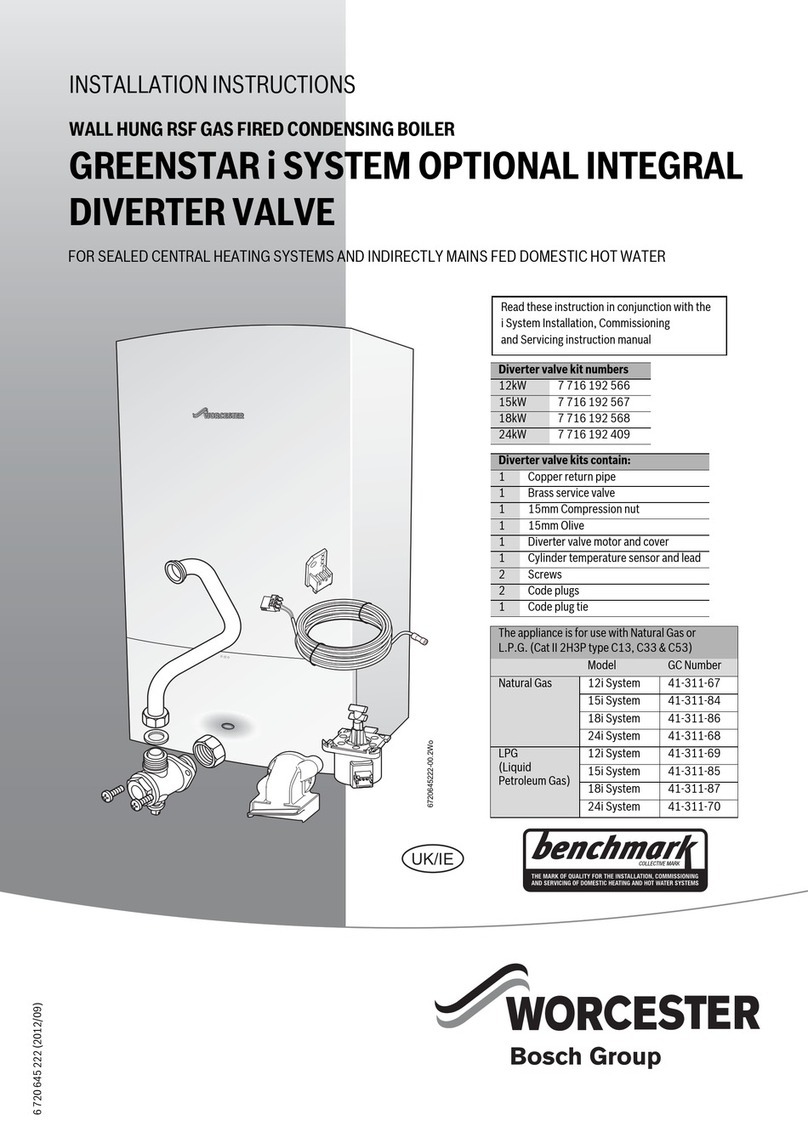

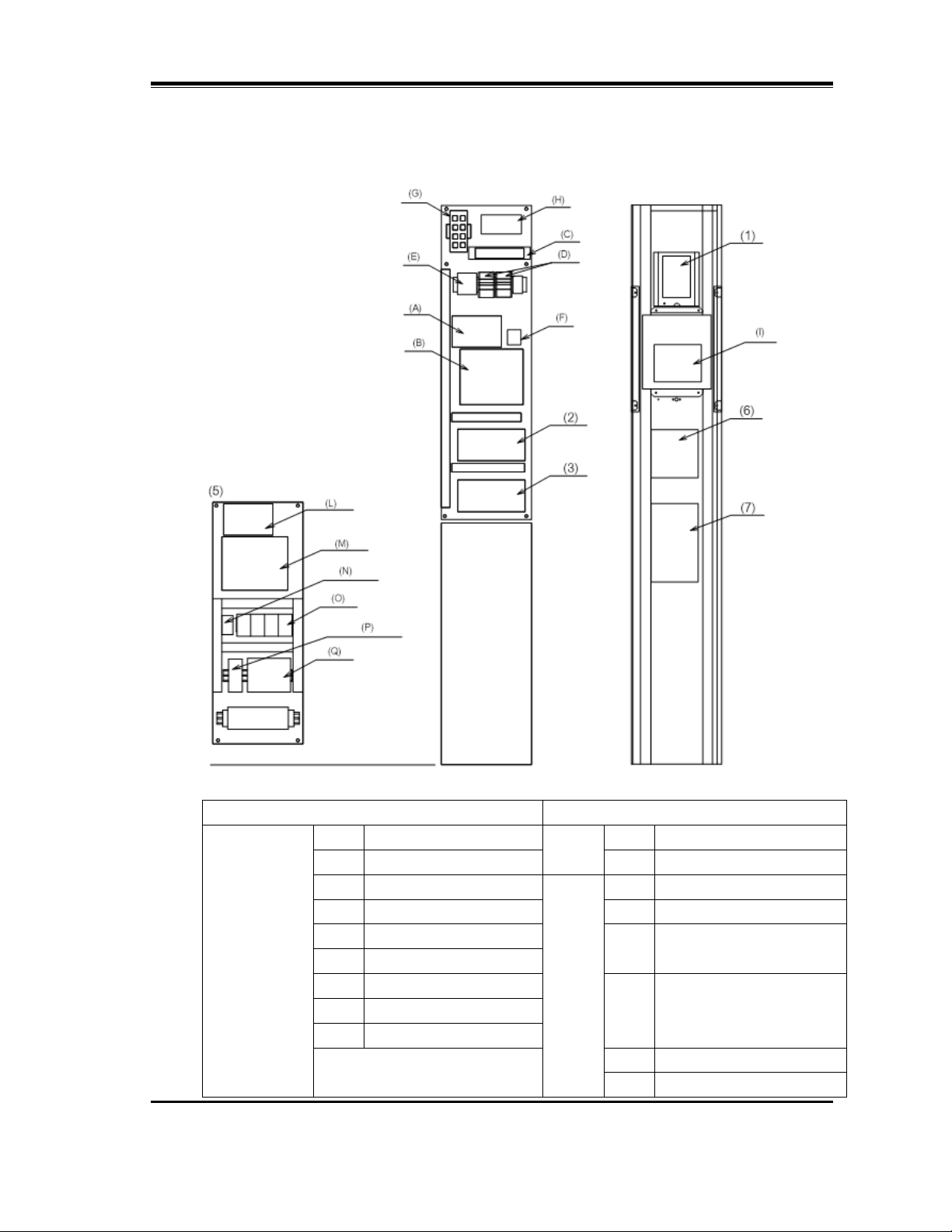

2.2 Layout and Names of Internal Parts ..................................................................................... 3

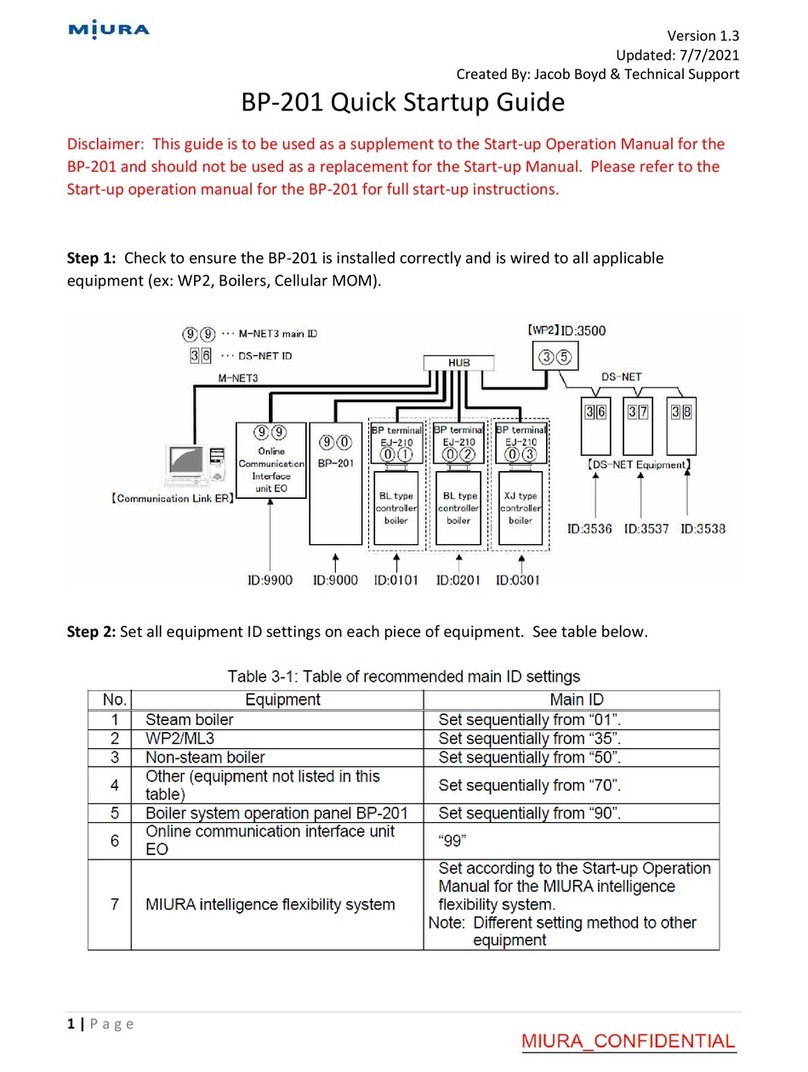

2.3 Options and Equipment Configuration.................................................................................. 4

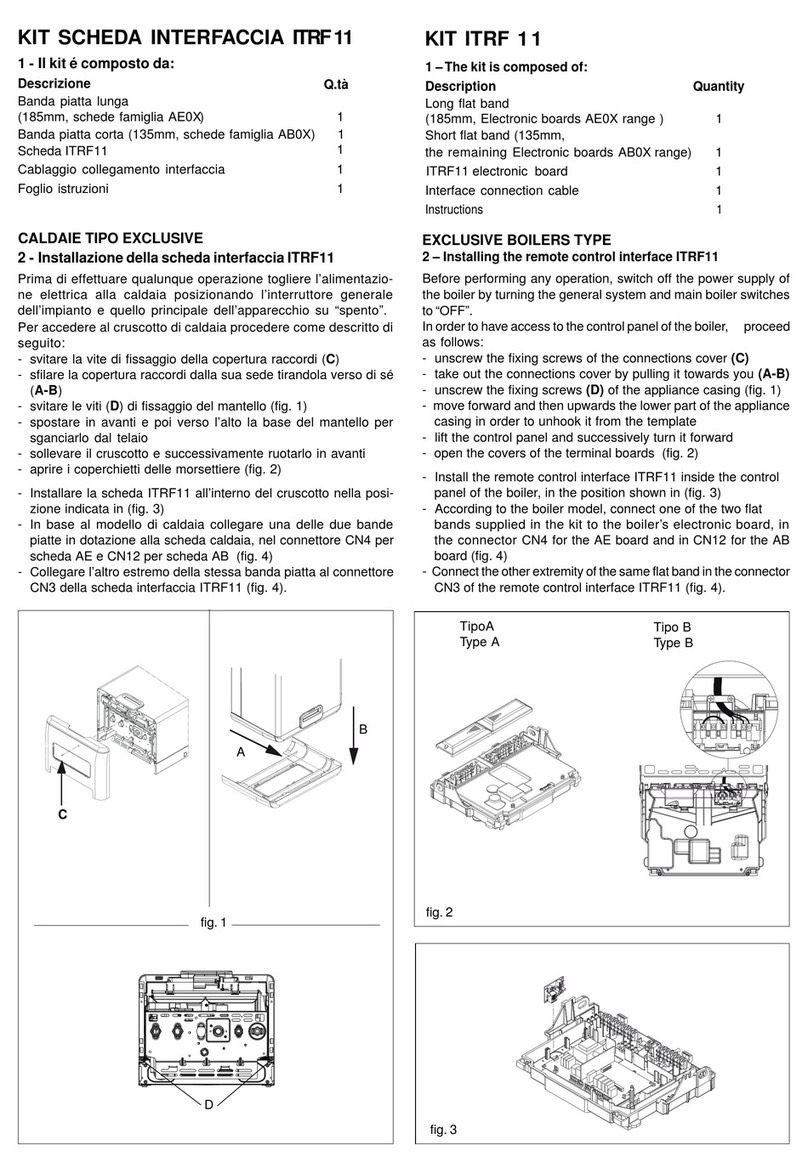

3. Accessories .......................................................................................................... 5

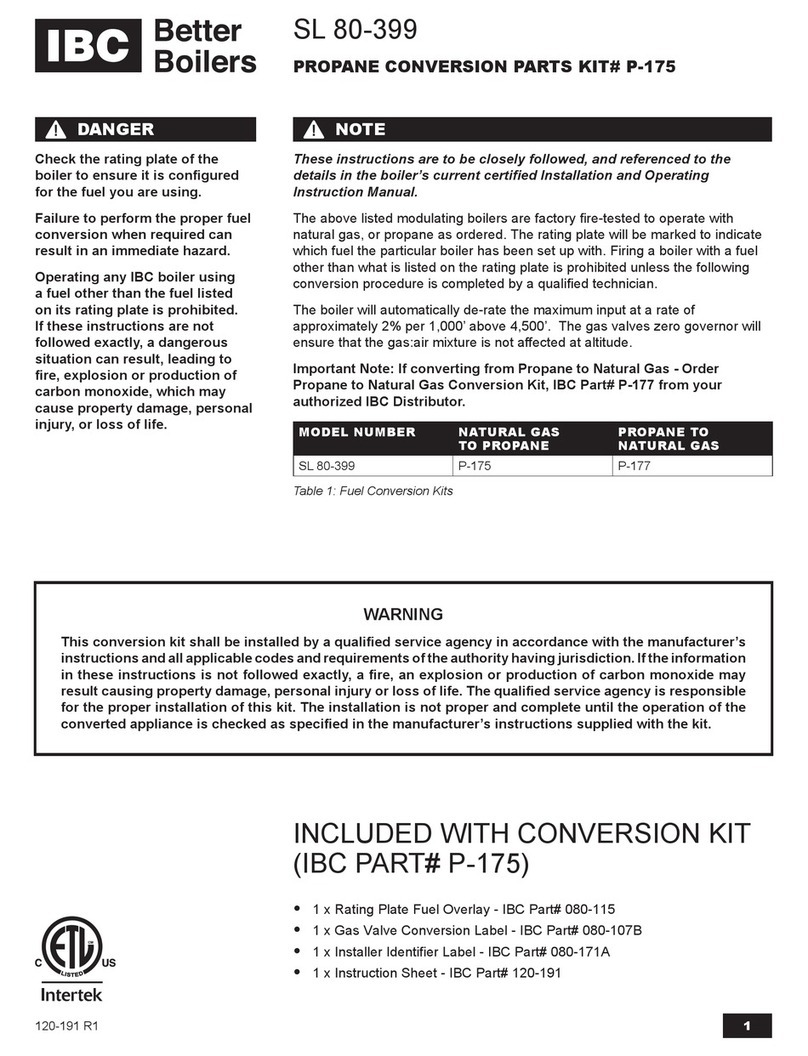

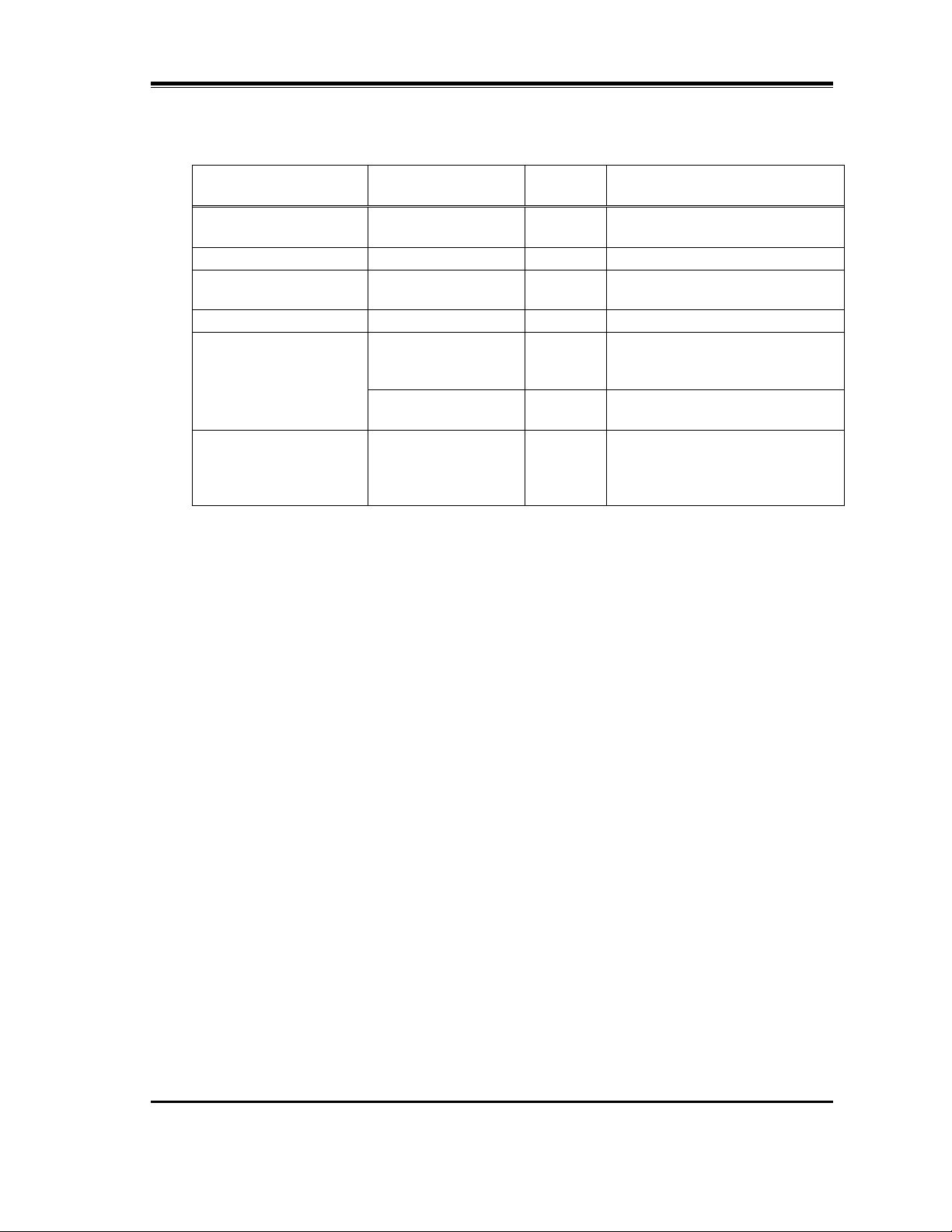

3.1 Steam Pressure Sensor........................................................................................................ 5

3.2 Steam Pressure Switch ........................................................................................................ 6

4. Carrying................................................................................................................. 7

5. Installation............................................................................................................. 7

5.1 Precautions when Installing the Main Unit ...........................................................................7

5.2 BP-201STA Installation ......................................................................................................... 9

5.3 Precautions when Installing the Steam Pressure Sensor and Steam Pressure Switch .... 10

6. Wiring Work .........................................................................................................11

6.1 Precautions ......................................................................................................................... 11

6.2 Wiring .................................................................................................................................. 12

6.3 Terminal Sequence of the Control Board ...........................................................................15

6.4 Wires and Terminal Processing .......................................................................................... 18

6.5 Steam Pressure Sensor Wiring .......................................................................................... 19

6.6 Steam Pressure Switch Wiring ........................................................................................... 20

6.7 M-NET3 Cable Wiring......................................................................................................... 21

6.8 Earthquake Detector Wiring................................................................................................ 22

6.9 Flowmeter Wiring................................................................................................................ 23

6.10 Wiring the Dry Contact Inputs and Dry Contact Outputs.................................................... 23

6.11 Telephone Line Wiring ........................................................................................................ 24

6.12 Wiring the Water Treatment Control Unit for Boiler WP2 ................................................... 24

6.13 Wiring the DS-NET Communication Unit ML3 ................................................................... 24

7. Attaching the MI Number Label......................................................................... 25