Table of Contents

iv

Table of Contants

1 Precautions .................................................................................................................................................... 1

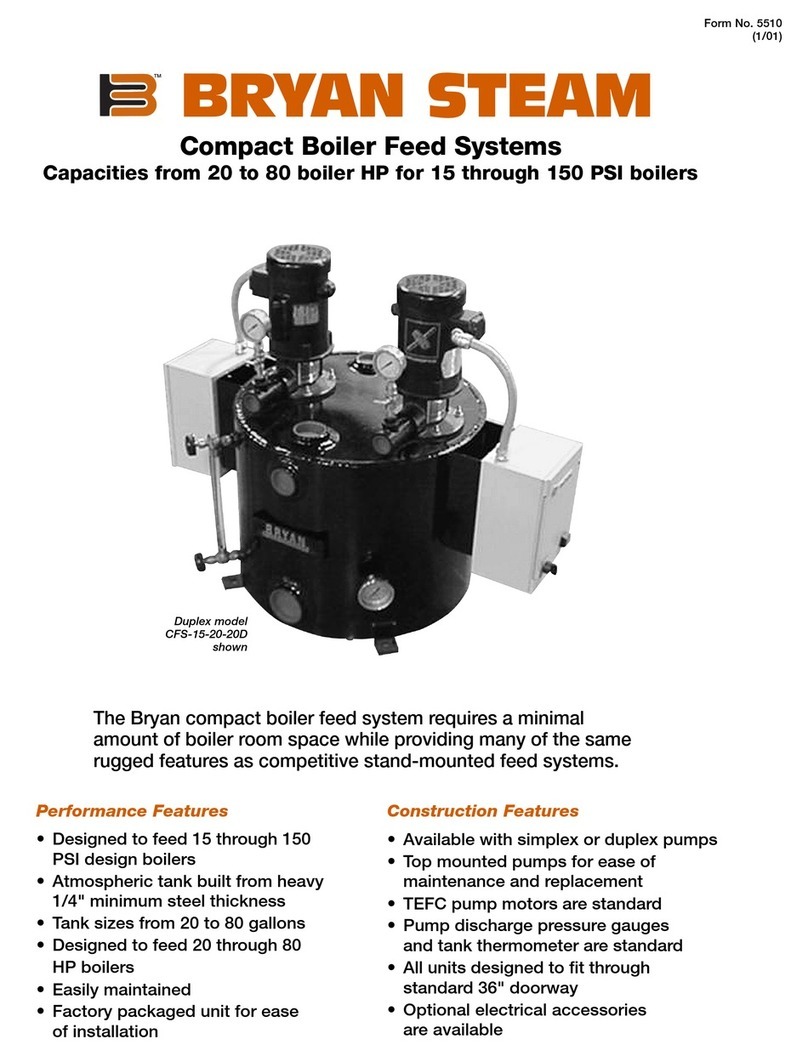

2 Outside View Drawings.................................................................................................................................. 2

2.1 Outside View Drawings.......................................................................................................................... 2

3 Moving........................................................................................................................................................... 3

3.1 Dimensions ............................................................................................................................................ 3

3.2 Moving Instruction................................................................................................................................. 3

3.3 Compornents ......................................................................................................................................... 3

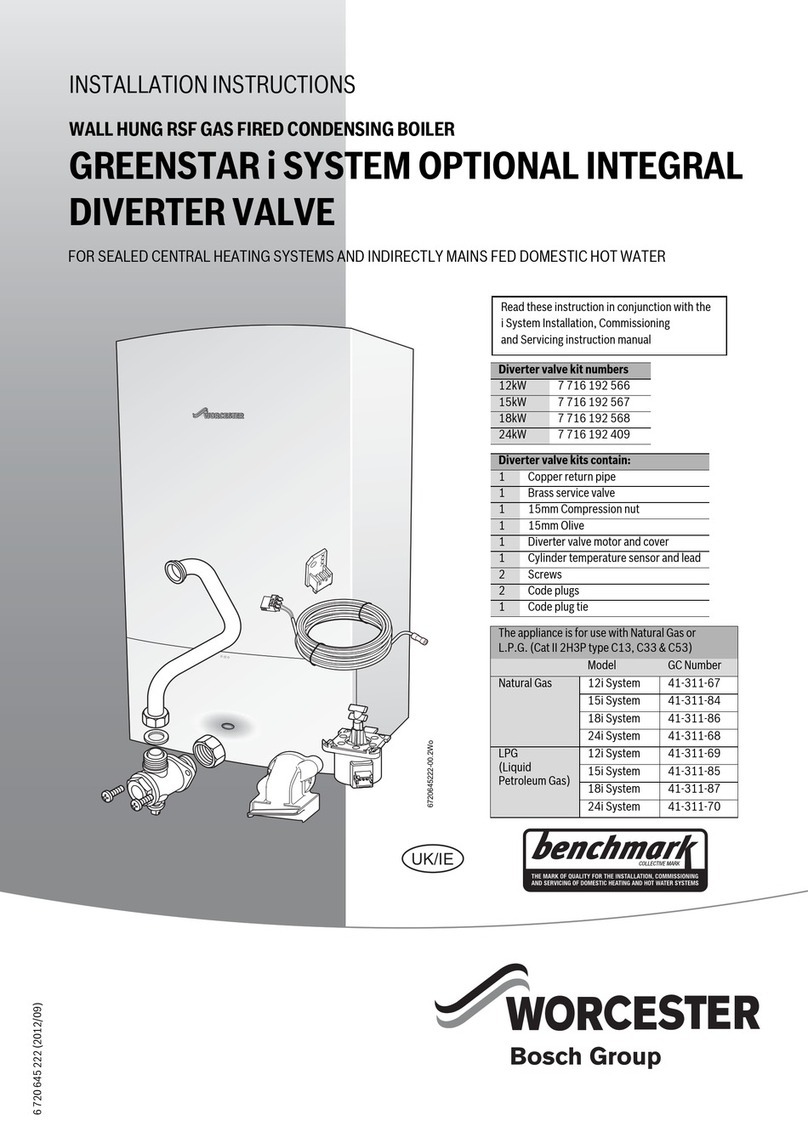

4 Installation ..................................................................................................................................................... 4

4.1 Installation Suggestions ......................................................................................................................... 4

4.2 Mounting ............................................................................................................................................... 5

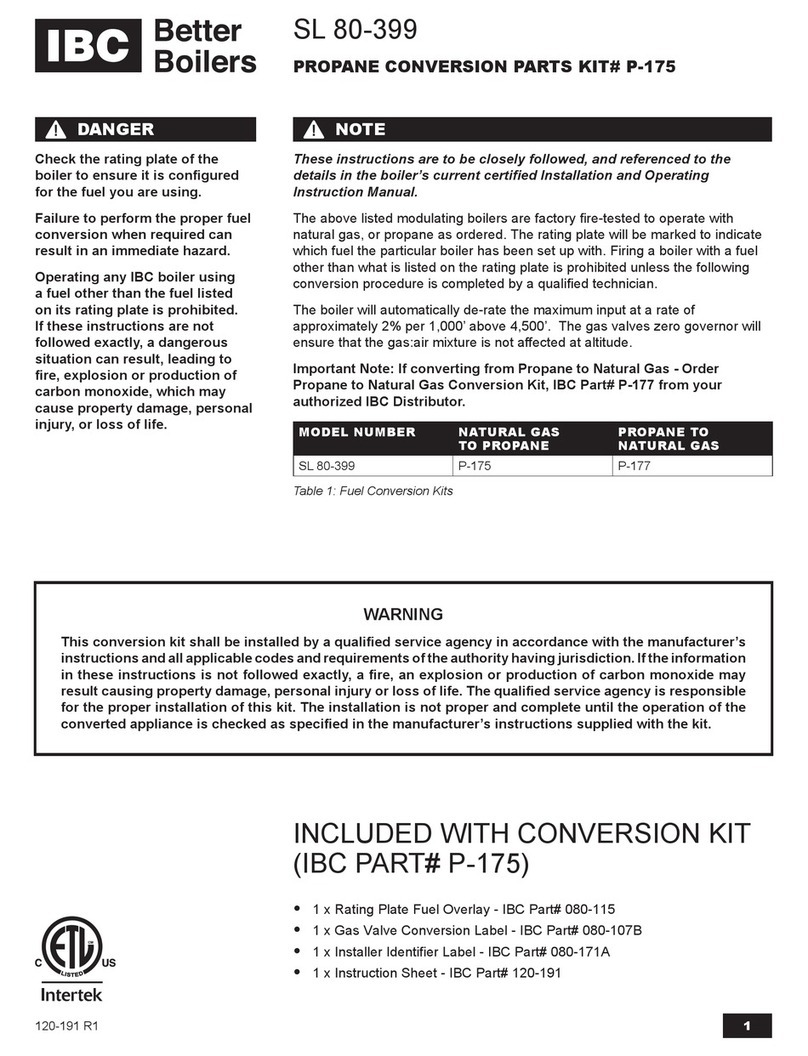

5 Wirings........................................................................................................................................................... 6

5.1 Cable Holes ............................................................................................................................................ 6

5.2 Main Power and Ground Wirings .......................................................................................................... 6

5.3 Signal Wirings ........................................................................................................................................ 7

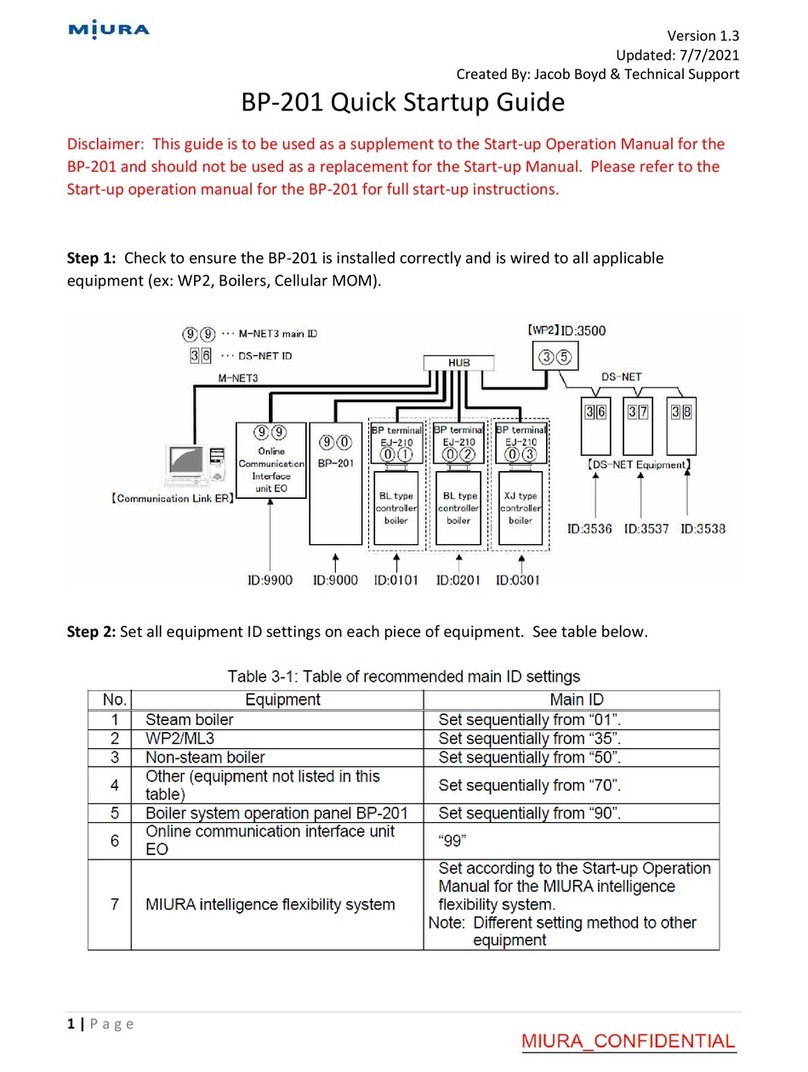

5.4 Boiler Network Wirings.......................................................................................................................... 8

5.5 Modbus TCP Wirings............................................................................................................................ 10

6 IPC Installation and Wirings......................................................................................................................... 12

6.1 IPC Installation ..................................................................................................................................... 12

6.2 IPC Wirings........................................................................................................................................... 14

7 Specifications............................................................................................................................................... 18