Document No. E20-036-01

1

Table of Contents

1. PRECAUTIONS REGARDING INSTALLATION ...................................2

2. OVERALL DIMENSIONS ......................................................................3

2.1. MP1-200 Overall Dimensions..............................................................................3

2.2. MT1-200 Overall Dimensions ..............................................................................4

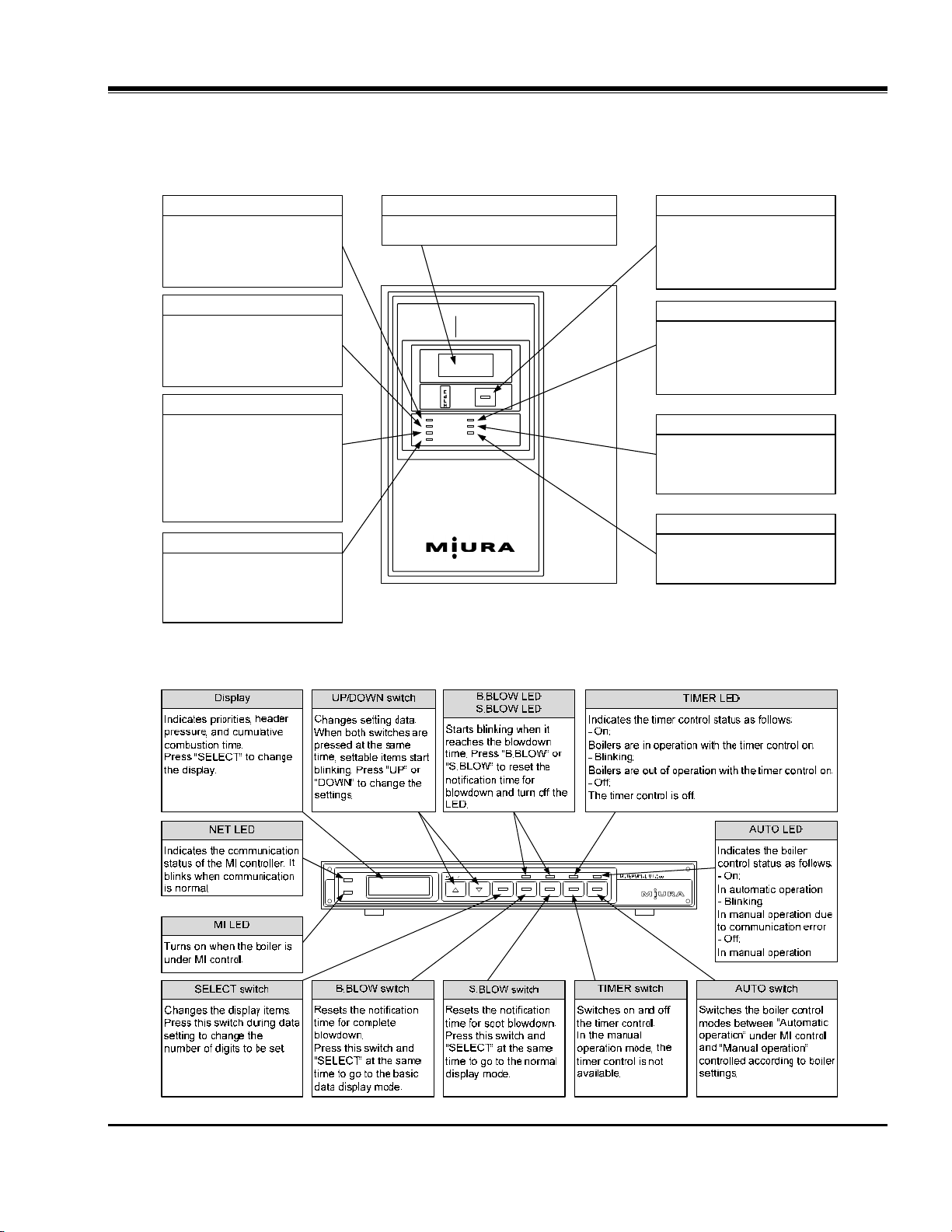

3. COMPONENT NAMES ..........................................................................5

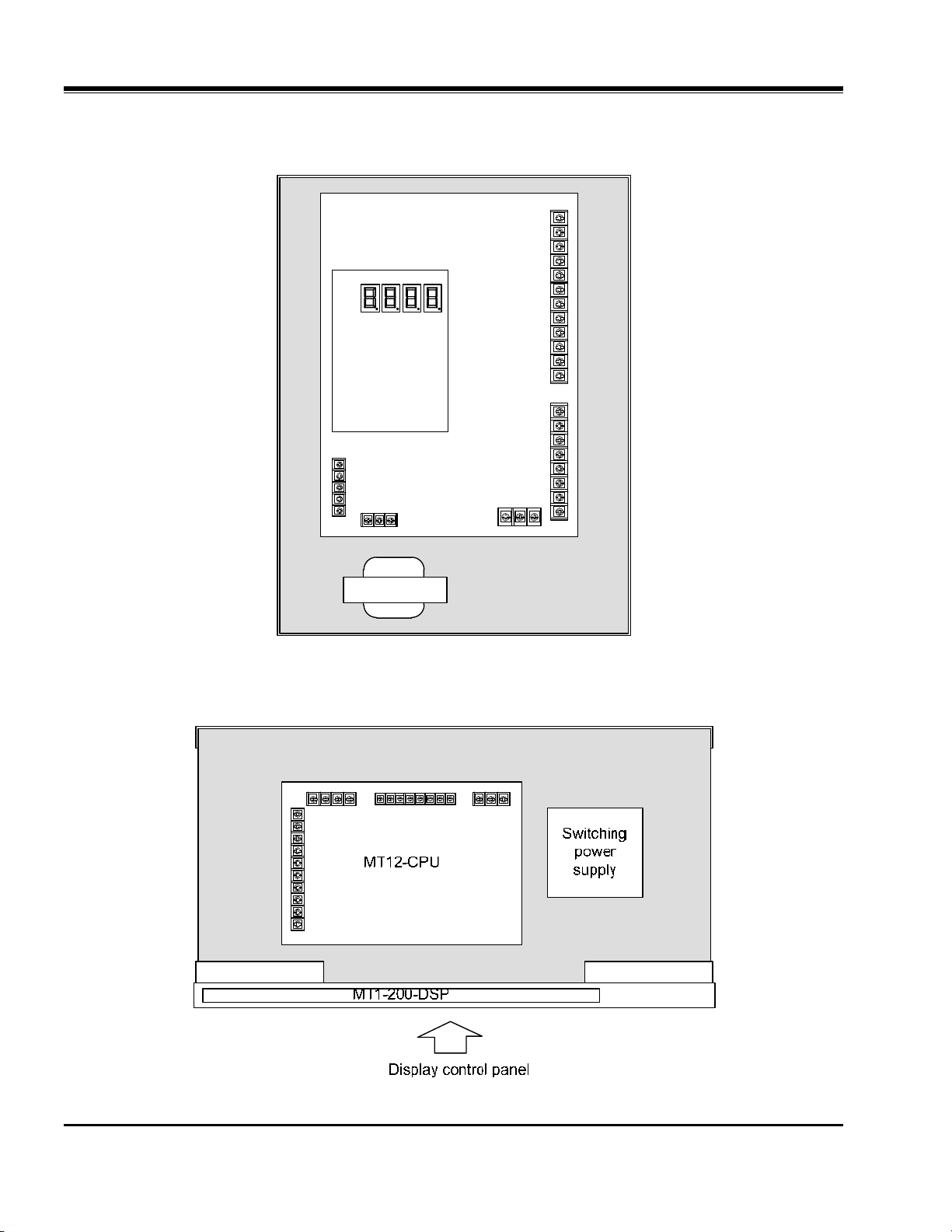

3.1. Components of Display Control Panel.................................................................5

3.2. Internal Circuit Board Layout and Component Names ........................................6

4. PARTS ...................................................................................................7

4.1. Main Unit .............................................................................................................7

4.2. Accessories .........................................................................................................7

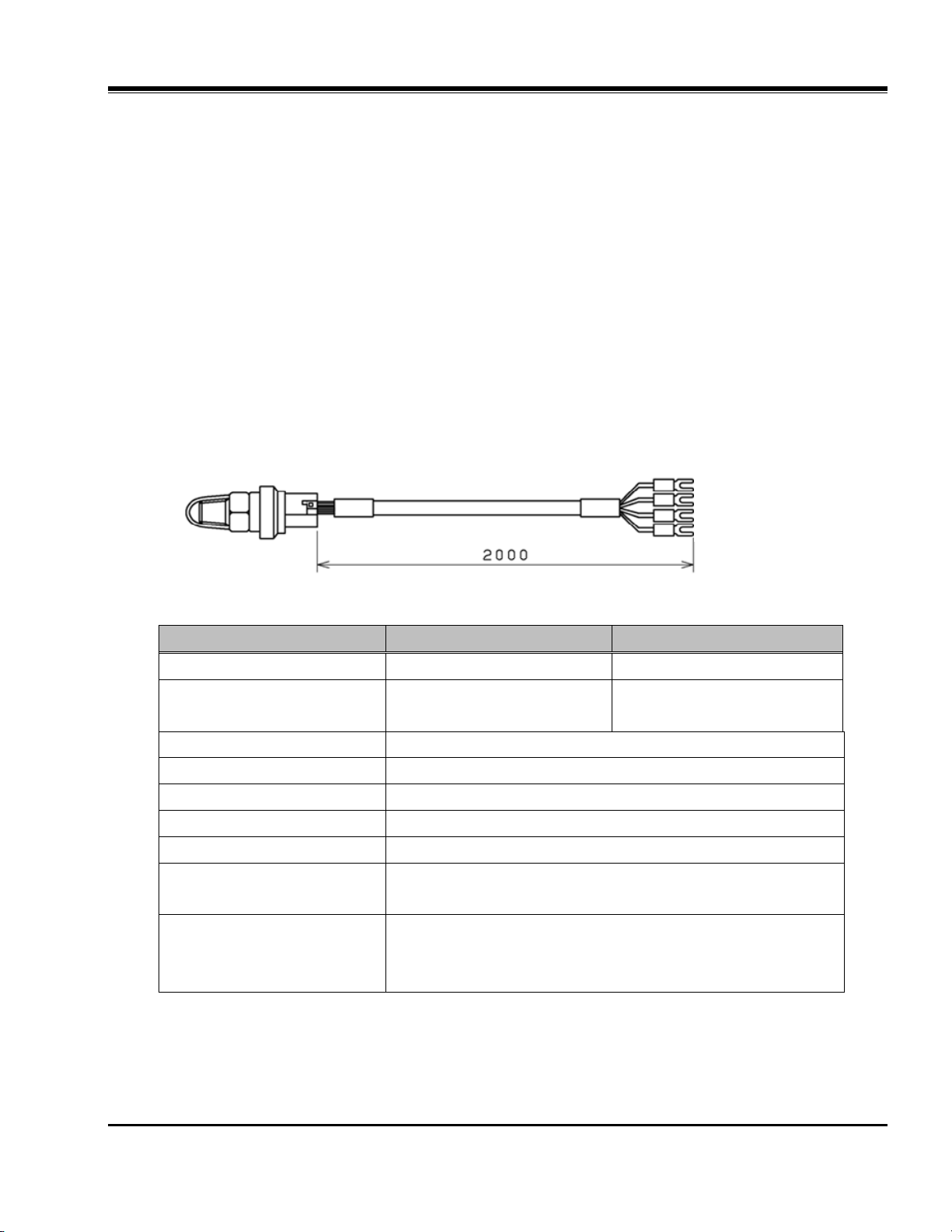

4.2.1. Steam Pressure Sensor ................................................................................ 7

4.3. Parts Required for Installation .............................................................................8

5. INSTALLATION......................................................................................9

5.1. Precautions when Performing Unit Installation ....................................................9

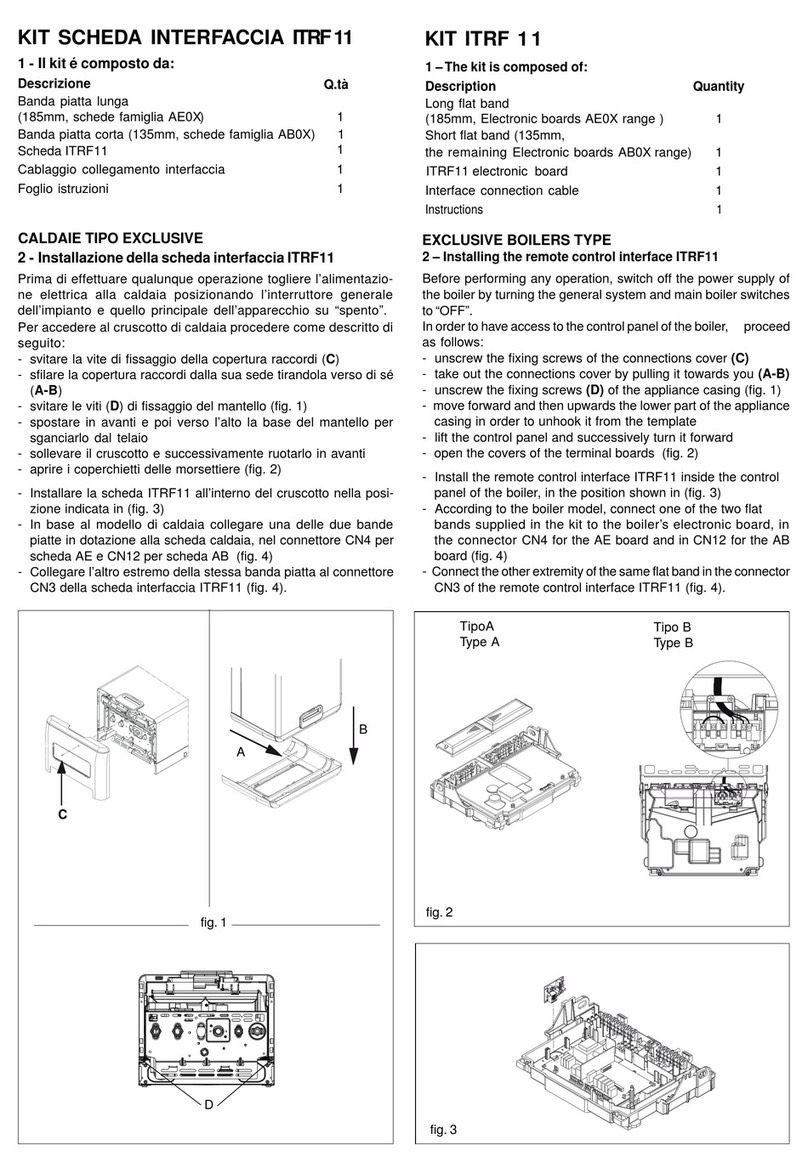

5.2. MP1-200 Installation Procedure ........................................................................10

5.3. MT1-200 Installation Procedure......................................................................... 11

5.4. Precautions when Installing Steam Pressure Sensor ........................................12

6. WIRING ................................................................................................14

6.1. Precautions........................................................................................................14

6.2. Wiring Procedure...............................................................................................15

6.3. Terminal Layout on the Control Board ...............................................................16

6.4. Wires .................................................................................................................17

6.5. Input/Output Signal Wire ...................................................................................18

6.6. MI-NET Communications Wiring .......................................................................21

6.7. Steam Pressure Sensor Wiring .........................................................................22

6.8. Earthquake Detector Wiring ..............................................................................23

7. WIRING EXAMPLE..............................................................................24

7.1. Boiler with XJ Controller Installed ......................................................................24

7.2. Boiler with BL Controller Installed......................................................................25

8. MI NUMBER PLATE ATTACHMENT...................................................26

8.1. Attachment Procedure .......................................................................................26

8.2. Attachment Location ..........................................................................................26