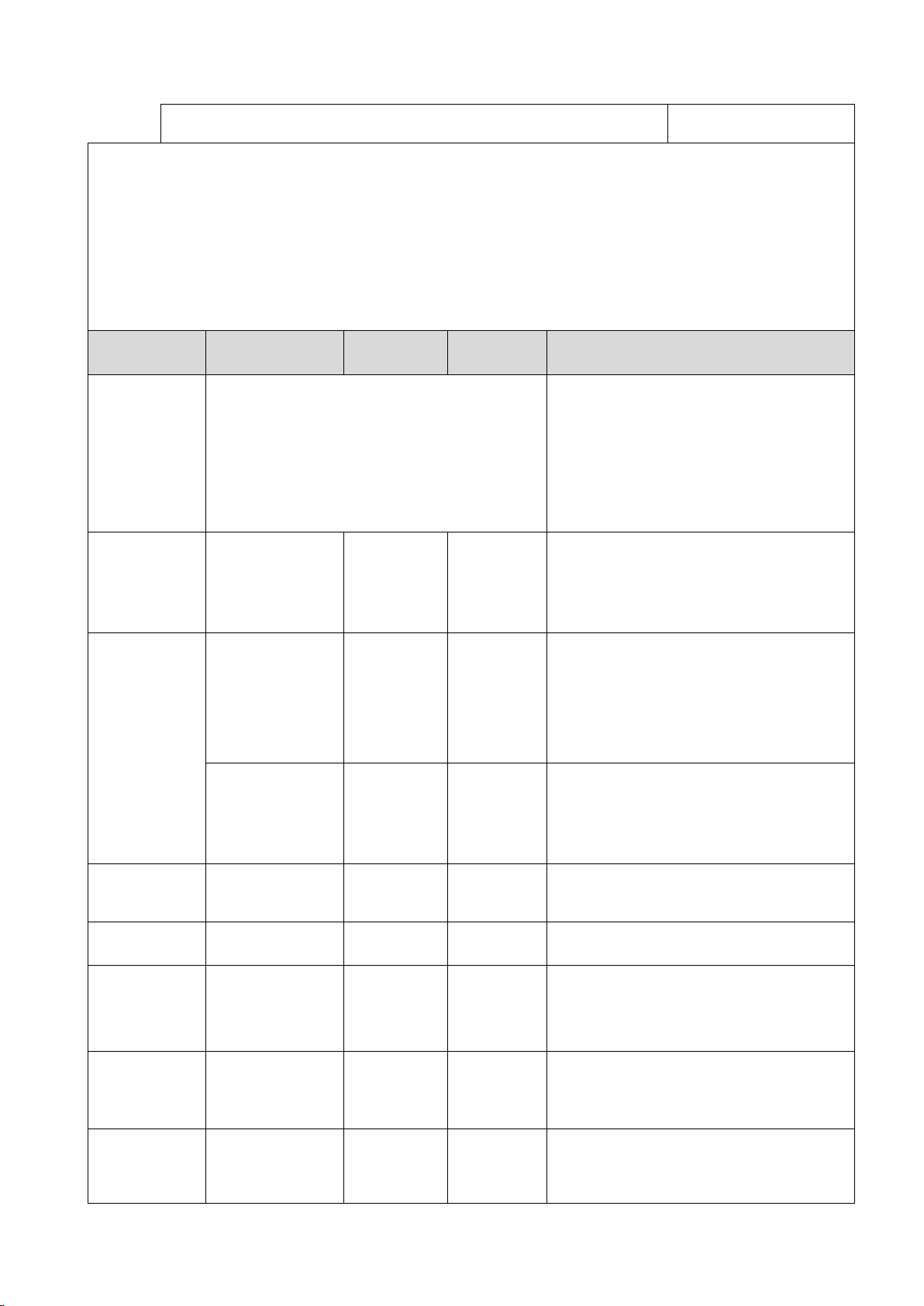

Applicable to All Water Treatment Equipment (Related Laws and Regulations)

<Precautions for installation and use> —Related laws and regulations

1) The table below shows part of the laws and regulations on equipment installation and use. Refer to the separate

document for more information on other relevant laws and regulations.

(There are also prefectural and municipal ordinances; therefore, contact the supervisory authority or competent

authority for more information.)

2) The information listed in the table was created based on the laws and regulations in effect when the information was

published.

3) The documents to be submitted and their destination vary depending on your equipment and facilities.

If you have any questions, contact your nearest dealer, MIURA sales office, or the competent supervisory authority.

4) The laws and regulations listed below may not apply to all water treatment equipment. Refer only to those laws and

regulations that apply to your equipment and facilities.

Related laws

and regulations

Water Quality

Pollution Control

Act, River Act,

Sewerage Service

Act, etc.

Verification required from local towns and cities in which

the water treatment equipment or other equipment is

installed.

(The laws and regulations in some areas may be defined

even more specifically in accordance with regional

regulations.)

Drain water may be produced depending on the type

of water treatment equipment and equipment

operation. Drain water must be treated in other ways

to prevent it from damaging waterways and the like.

In cases where the total amount of drain water

exceeds the legal amount on a per-plant basis or

where the equipment is used at specified facilities,

an application is necessary. However, the conditions

may vary from region to region. Accordingly, you

should contact your local authorities for more

information.

Regional Pollution

Prevention

Ordinance

Notification as

required by the

applicable ordinance

As set forth by

the relevant

regional

authorities

As set forth by

the relevant

regional

authorities

Applicability is defined independently by regional

pollution prevention ordinances based; accordingly,

you should contact your local authorities for more

information. (Certain regional ordinances concerning

air pollution, noise, vibration, drain water, and the

like may supersede the corresponding national

regulations.)

(Prohibition of direct waterworks contact)

Water treatment equipment (excluding certified

equipment) cannot be connected directly to

waterworks. Instead, it is necessary to either set up

a feed water tank or to isolate the systems using, for

example, a float valve.

Details may vary from region to region; accordingly,

you should contact your local authorities for more

information.

Design specifications

for dedicated

waterworks,

Notification of the

start of feeding water

As set forth by

the relevant

regional

authorities

Business operators are to submit notification to local

governments for drinking water wells for industrial

use in facilities where the volume of water intake

exceeds the allowed quantity as prescribed by law

which require the use of dedicated waterworks

systems regardless of the form of usage. Contact

your local authorities for details.

Act on

Maintenance of

Sanitation in

Buildings

Buildings are to be preserved and maintained

(through cleaning, water quality analysis, and other

activities) in accordance with Hygiene Control

Standards.

No notification made

for equipment and

related matters

Measures are to be implemented to maintain

hygiene and safety and prevent sanitation hazards

in accordance with applicable laws.

Industrial Safety

and Health Act

When using substances specified in applicable laws

(such as specified chemical substances), a qualified

operator must be selected, all such substances are

to be handled and managed in accordance with

applicable laws, and the operator’s healthcare is

necessary.

Poisonous and

Deleterious

Substances

Control Act

All such substances are to be stored and managed

in accordance with applicable laws. Chemical

substances are to be handled properly in

accordance with the guidance and information listed

on the SDS for the relevant material.

Notification as set

forth by local fire

departments

The nearest

fire department

Prior to the

start of work

Local fire chiefs or fire department chiefs must be

notified in advance of any plans for any party to use

or store certain substances (chemical substances

and other materials) of a designated quantity as

specified by applicable laws and regulations.