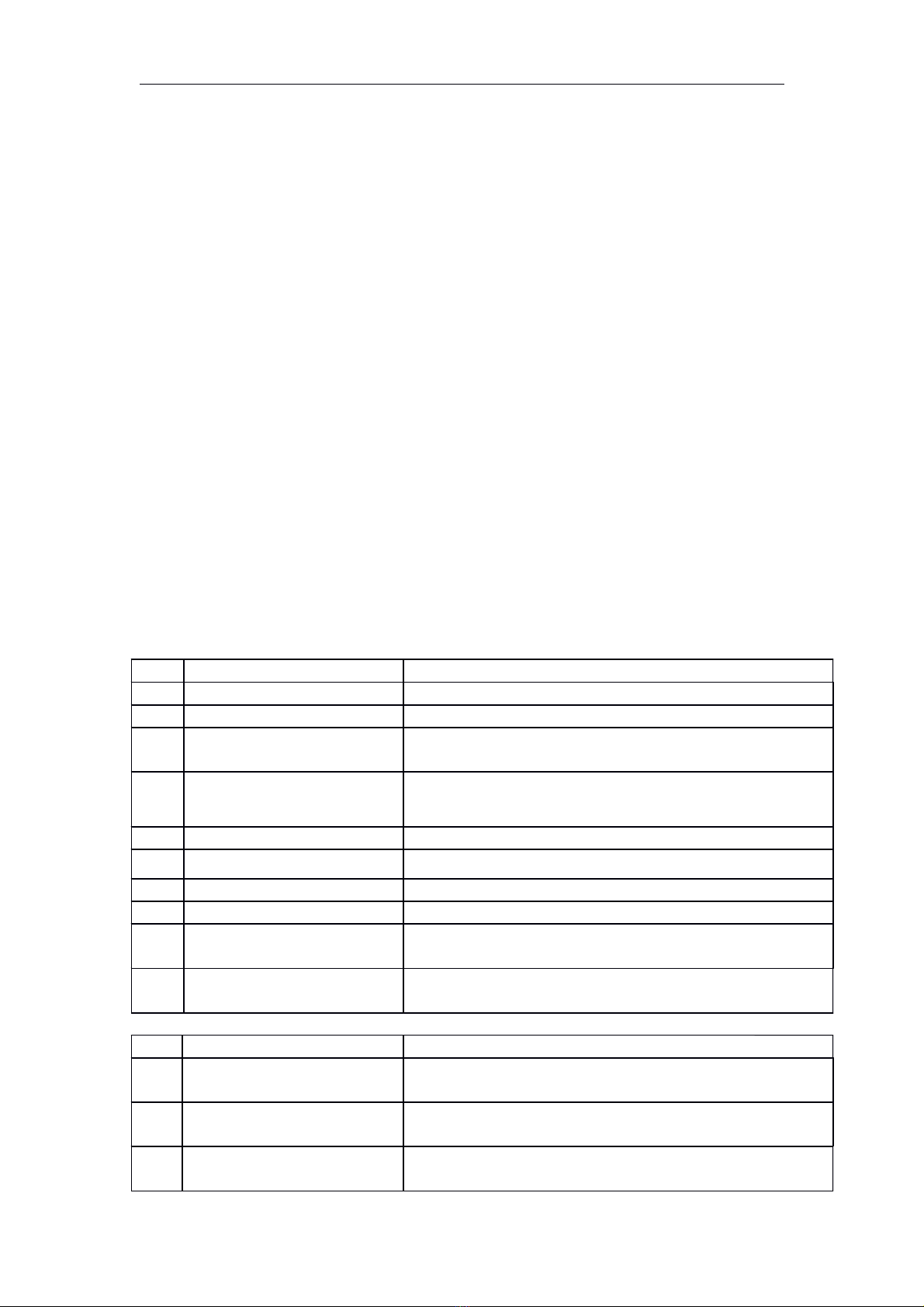

dissolution

Close the air

discharge valve

Local pressure-2℃( Default 98℃);Setting from(80-

110℃)

Note:

a. Parameters can be set except for the

fixed ones. Drying phase starts when

the time limit of 4 min for water

discharge exhausts or the temp. drops

to 100℃.

b. Water is discharged when the temp.

drops to 105~110℃. When the temp.

dropping to 80℃, alarm rings notifying

: “sterilization completed, please open

the door”

Water discharge

setting

Water discharge (open/close) after the sterilization can be set

freely;Temp. of water discharged (Default: discharging when the

temp. of water drops to 105℃)

Range: 6#Solid (Customize) 105~134℃; 7#Liquid (Customize):105-

110°C

Attention:The maximum temp. of air and water discharge can not exceed the sterilizing temp.

Introduction to the control panel:

There are five buttons: “Temp.”, “Time”, “▲”, ” ▼” and “Start/Stop”; 9 indicator

lights: “Add water”, “Temp. rising”, “Sterilizing”, “Air discharge”, “Drying”, “Finish”,

“Alarm”, “Liquid” and “Door”; and “Temp. display” and “Time display”.

Operating procedure:

Plug in, switch on the air switch on the left, and then turn on the rocker switch on

the panel. The panel lights on, the autoclave stands by. “Temp. diaplay” shows the

word, “Prog”. “Time display” shows number X (X is the number from 1 to 7)

which refers to the chosen program. Then “Time display” alternately shows the

current temp. and the set sterilizing time.

Choose different programs by pressing “▲”and“▼”. W h e n t h e f i f t h p ro g ra m ,

5#Liquid, is chosen, the light “Liquid” is on. When the seventh program, 7#Liquid

(Customize) is chosen, the light, “Liquid”, flashes, indicating users that the

current phase is “Liquid”-related. Then press “Start/Stop” to start the

sterilization.

After sterilization is complete, the "Finish" light, buzzer beep every 10

seconds."Finish" lights, the end of this sterilization, then confirm the gauge

pointer back to zero, counter-clockwise on the lid hand-wheel, open the lid, and

remove the items.

Note: