Contents

Safety Precautions..........................................................................................................................................0

1. Specifications.............................................................................................................................................0

2. Scope of application...................................................................................................................................0

3. Environmental conditions ..........................................................................................................................0

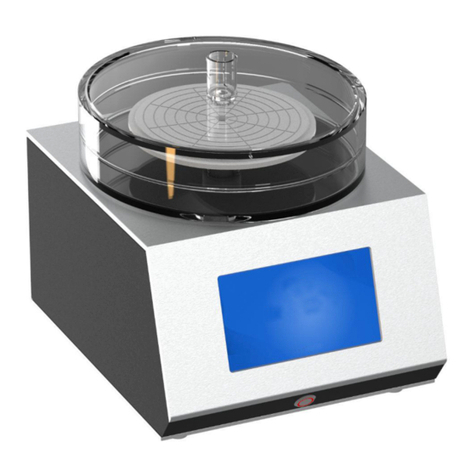

3.1 Basic operating conditions ...............................................................................................................0

3.2 Transport and storage conditions......................................................................................................0

4.1 Mounting position............................................................................................................................1

4.2 Connection between power cable and ground wire..........................................................................1

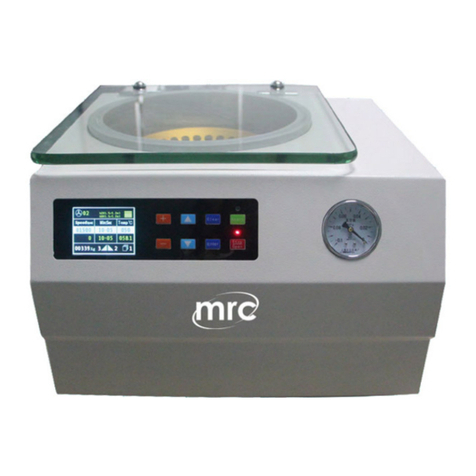

5. Structure.....................................................................................................................................................1

6. Operating panel..........................................................................................................................................2

7. Rotor preparation........................................................................................................................................3

7.1 Prepare the samples to be separated.................................................................................................3

7.2 Transfer the samples into the centrifuge tube...................................................................................3

7.3 Ensure the balanced centrifuge tube.................................................................................................4

7.4 Check rotor.......................................................................................................................................4

7.5 Symmetrically load centrifuge tubes into rotor ................................................................................4

8. Operation....................................................................................................................................................4

8.1 Normal operation..............................................................................................................................4

8.2 RCF operation..................................................................................................................................7

8.3 Transient operation...........................................................................................................................8

9. Cleaning & Maintenance............................................................................................................................8

9.1 Cleaning ...........................................................................................................................................8

9.2 Wearing parts....................................................................................................................................9

9.3 Routine check...................................................................................................................................9

10. Common failures and solutions..............................................................................................................10

10.1 List of common failures ...............................................................................................................10

10.2 How to open the upper cover lid .............................................................................................11

10.3 Replace the fuse ...........................................................................................................................12

11. Introduction to rotor and centrifuge tube.............................................................................................12

11.1 Introduction to rotor .....................................................................................................................12

12. RCF calculation......................................................................................................................................14

13. Ordering information..............................................................................................................................15

14.Warranty.............................................................................................................................................15

14.1 Unit warranty................................................................................................................................15

14.2 Rotor warranty..............................................................................................................................15

After-sales services ......................................................................................................................................15