10 PremAire® Cadet Escape G1 US

4 Visual Inspection

Failure to follow this warning can result in serious personal injury or death.

4.1 All Components

1. Inspect all components for deterioration, dirt, cracks, debris, tears, holes, stickiness, signs of heat or chemical

related damage or other visible signs of damage.

2. Inspect all straps (shoulder pads, pull straps, lumbar pad, waist straps, facepiece head harness) for tears, cuts, wear,

abrasion, missing buckles or straps.

3. Perform all component specific inspections listed below.

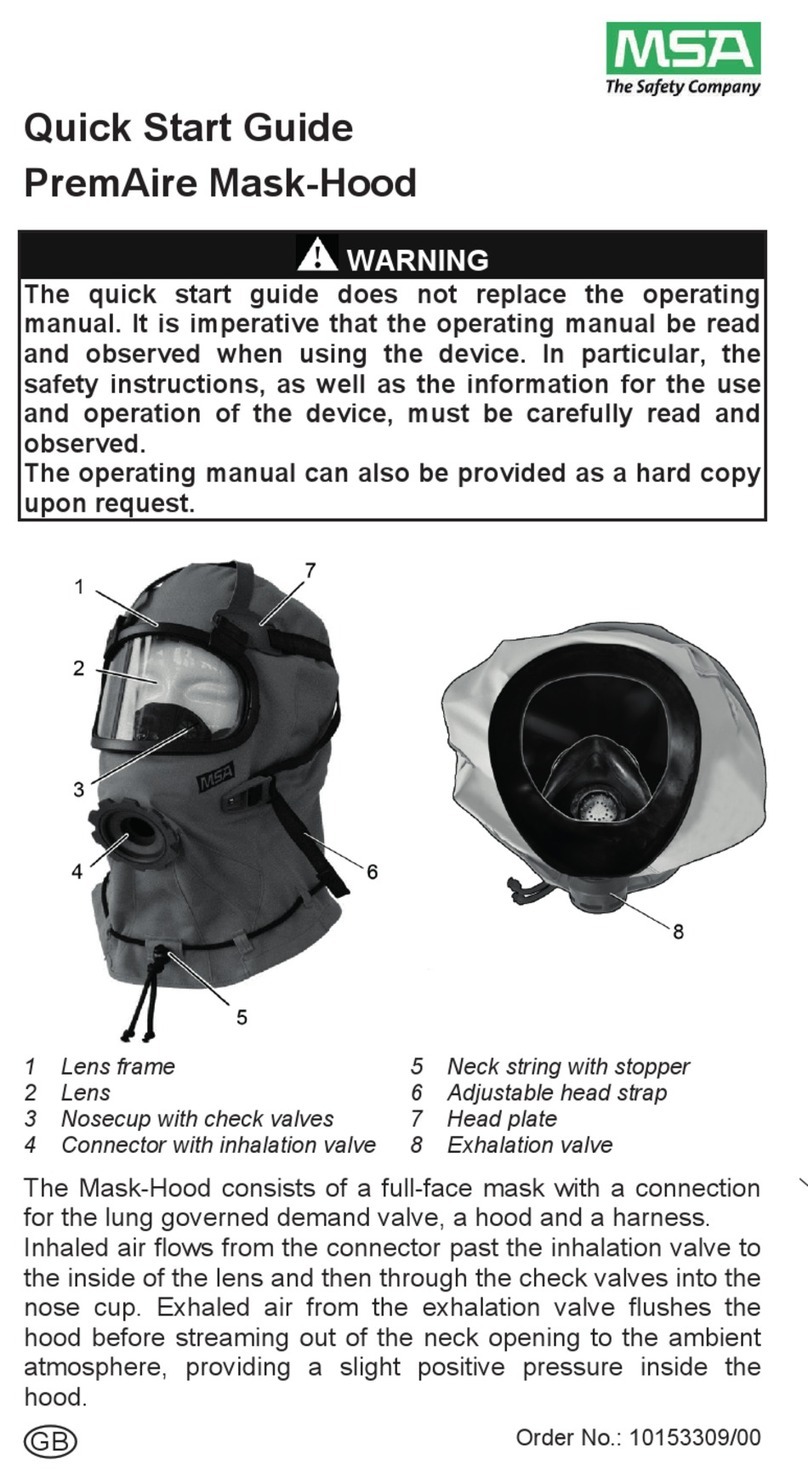

4.2 Facepiece

1. Inspect the lens for cracks, scratches, deformation, and color change.

2. Check the facepiece rubber for a tight seal and secure fit to the lens ring.

3. Ensure the exhalation valve is clean and operates easily. The valve must move off the seat and return when released

(from inside the facepiece).

4. Inspect the facepiece inlet for damage. Ensure the inhalation valve is in place.

5. Inspect the nosecup to ensure the check valve are in place and the nosecup is secure to the component housing.

4.3 Regulator

1. Ensure that moisture or debris is not present, especially inside the regulator.

2. Ensure the o-ring and seal ring are free of debris and not damaged or missing.

3. If the SCBA is equipped with a quick connect hose, inspect the rubber seal for deterioration, dirt, cracks, tears, or

tackiness.

○ Inspect the quick connect fittings.

○ Ensure that the openings are clear and free of debris and other contaminants.

○ Ensure that the quick connect fittings operate properly and are secured.

4.4 Cylinder and Valve Assembly

Breathing apparatus cylinders should be recharged as soon as possible after use. Cylinders should not be stored partially

charged for two reasons:

If used without recharge, the service life of the respirator is reduced.

The cylinder burst disc vents excess pressure if a full cylinder is over exposed to fire or heat. If the cylinder is not full, it may

be damaged before the burst disc vents.

1. If the cylinder is less than FULL, recharge it before storing it. Cylinder air must be at least CGA Quality Verification

Level (Grade) D respirable air.

2. Inspect the cylinder valve for signs of damage.

3. Inspect the cylinder body for cracks, dents, weakened areas, corrosive agent, causing the fibers to break or peel, or

signs of heat-related damage. If the cylinder is damaged return it to an MSA Service Center. Call 1-800-MSA-2222

for instructions.

4. Check the hydrostatic test date on the cylinder approval sticker located on the cylinder neck. Aluminum and carbon

fiber cylinder must be tested every five years.

5. Ensure the needle and gauge face on the cylinder valve gauge are clearly visible and that the gauge stem is not bent.

6. Inspect the high pressure relief device. Verify that the relief holes are clear and free of debris or other contamination.

7. Inspect the intermediate pressure relief valve. Verify that the relief holes are clear and free of debris or other

contamination.

8. Inspect the valve assembly seal ring to verify that it is present and properly seated. Inspect the seal ring for rubber

deterioration, dirt, cracks, tears, holes, or tackiness.

9. Inspect the hose connections. Verify that the hoses are properly secured.