Table of Contents

PREPARING THE HD-CX1600/1700/1750 (C9xx) PRINTER...................................................................3

FEEDER STAND ASSEMBLY AND STAND HEIGHT ADJUSTMENT.................................................5

Feeder Stand Assembly..............................................................................................................................5

Setting the height of the stand to match your printer.................................................................................7

Attaching the feeder to the stand................................................................................................................8

Aligning the feeder with the printer and final stand height adjustment.....................................................9

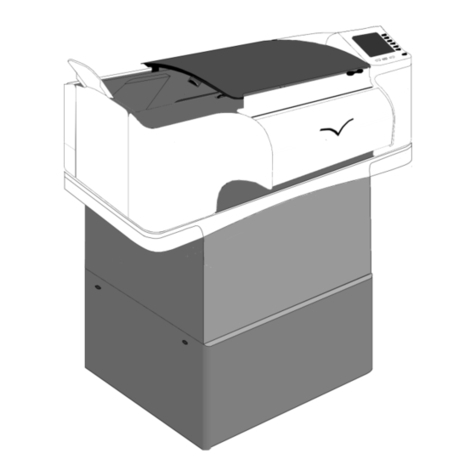

HD-CXENVL-FDR FEEDER OVERVIEW...............................................................................................13

Component Identification.........................................................................................................................13

Features and function...............................................................................................................................14

Time-out (out of paper) Feature...............................................................................................................14

SETTING UP THE FEEDER......................................................................................................................15

Setting the Hopper Paper Guides.............................................................................................................15

Setting the Sheet Separator(s)..................................................................................................................17

Setting up the envelope support wedge (back wedge).............................................................................19

Setting the Envelope Support Wedge for Other Envelope Types............................................................22

Setting the delivery table paper guides ....................................................................................................23

Testing the feeder.....................................................................................................................................25

Setting the speed of the feeder .................................................................................................................27

RUNNING A JOB WITH THE FEEDER AND PRINTER........................................................................28

DETACHING THE FEEDER FROM THE PRINTER...............................................................................33

IMPORTANT OPERATING TIPS/NOTES................................................................................................34

Suggested Feeder Speed Settings.............................................................................................................34

Feeder Ready Lever Function..................................................................................................................34

How to Pause/Resume Print.....................................................................................................................34

Automatic “Feeder Ready Lever” Reset..................................................................................................35

Avoiding false “Paper Jam” conditions ...................................................................................................35

TROUBLESHOOTING...............................................................................................................................36

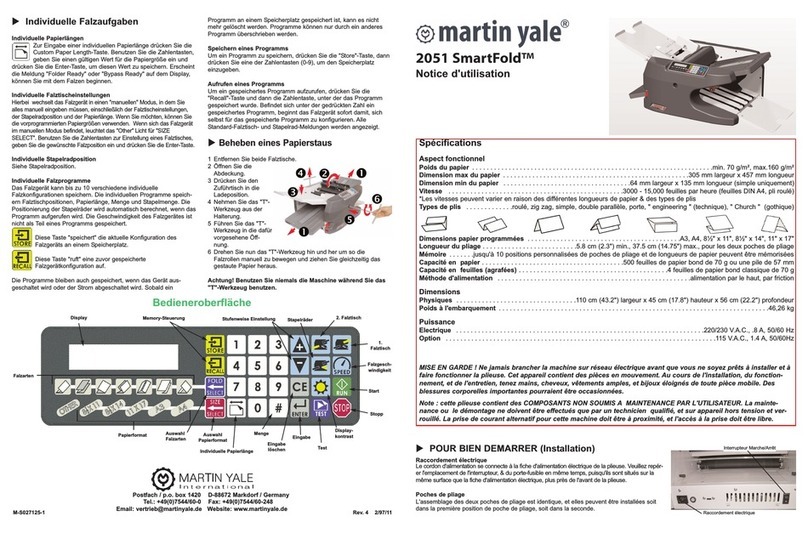

SPECIFICATIONS......................................................................................................................................38

OPERATOR MAINTENANCE ..................................................................................................................38

OPTIONAL HARDWARE..........................................................................................................................39

The HD-CXENVL-FDR feeder is designed to operate with the Neopost HD-CX Digital Color LED printers.

This guide will show the proper way to prepare the printer for the envelope feeder along with setup and

operation of the feeder.