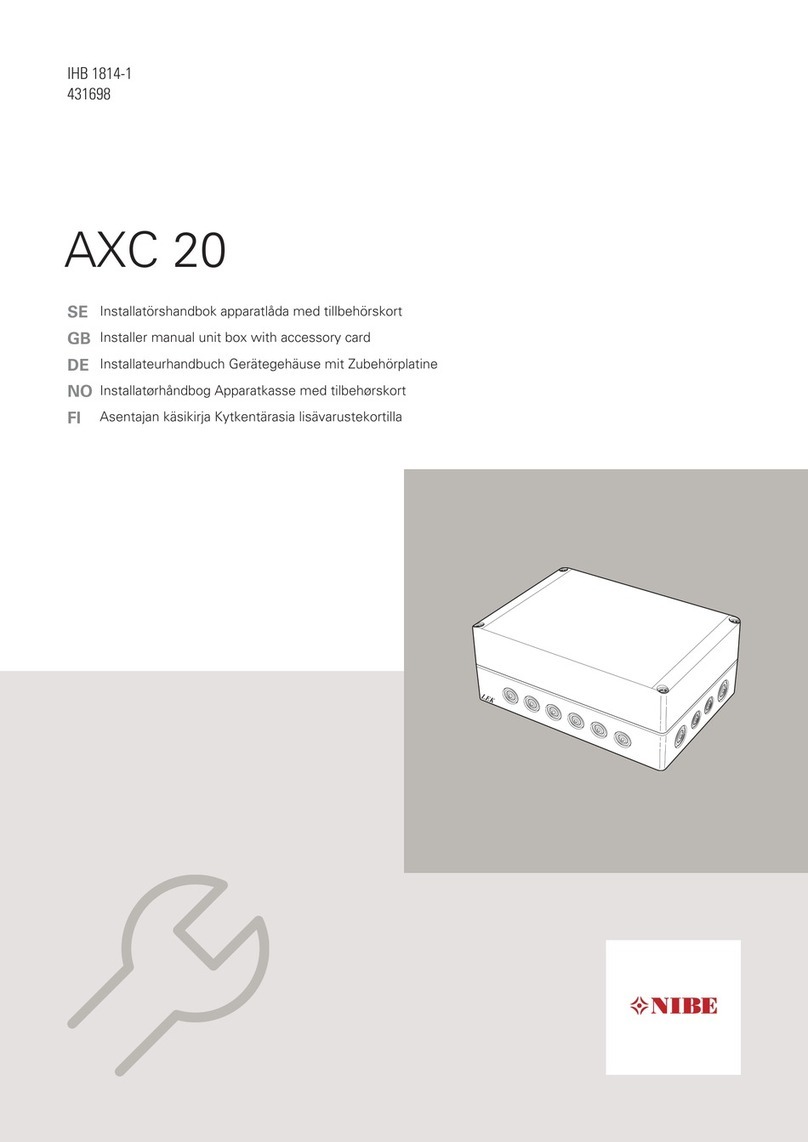

Safety information

This manual describes installation and service procedures

for implementation by specialists.

The manual must be left with the customer.

This appliance can be used by children

aged from 8 years and above and per-

sons with reduced physical, sensory or

mental capabilities or lack of experience

and knowledge if they have been given

supervision or instruction concerning use

of the appliance in a safe way and under-

stand the hazards involved. Children shall

not play with the appliance. Cleaning

and user maintenance shall not be made

by children without supervision.

Rights to make any design or technical

modifications are reserved.

©NIBE 2018.

NOTE

If the supply cable is damaged, only

NIBE, its service representative or

similar authorised person may re-

place it to prevent any danger and

damage.

Symbols

NOTE

This symbol indicates danger to person or ma-

chine .

Caution

This symbol indicates important information

about what you should observe when maintain-

ing your installation.

TIP

This symbol indicates tips on how to facilitate

using the product.

Marking

The CE mark is obligatory for most products sold

in the EU, regardless of where they are made.

CE

Classification of enclosure of electro-technical

equipment.

IP21

Danger to person or machine.

Read the User Manual.

General

Software version

The heat pump must have software version 8432R2

(F370)/3585R2 (F750) or later. Visit www.nibeuplink.com

and click on the tab "Software" to download the latest

software to your installation or use the enclosed USB

memory.

Serial number

The serial number can be found at the bottom left inside

the front cover.

Caution

You need the product's 14 digit serial number

for servicing and support.

Recovery

Leave the disposal of the packaging to the in-

staller who installed the product or to special

waste stations.

When disposing of the product, its constituent

materials and components, e.g. compressors,

fans, circulation pumps and circuit boards, must be dis-

posed of at a special waste station or dealer who

provides this type of service.

To access the separate components, refer to the section

that shows the construction of the product. No special

tools are required for access.

Improper disposal of the product by the user results in

administrative penalties in accordance with current legis-

lation.

SAM 40Chapter 1 | Important information4

1 Important information