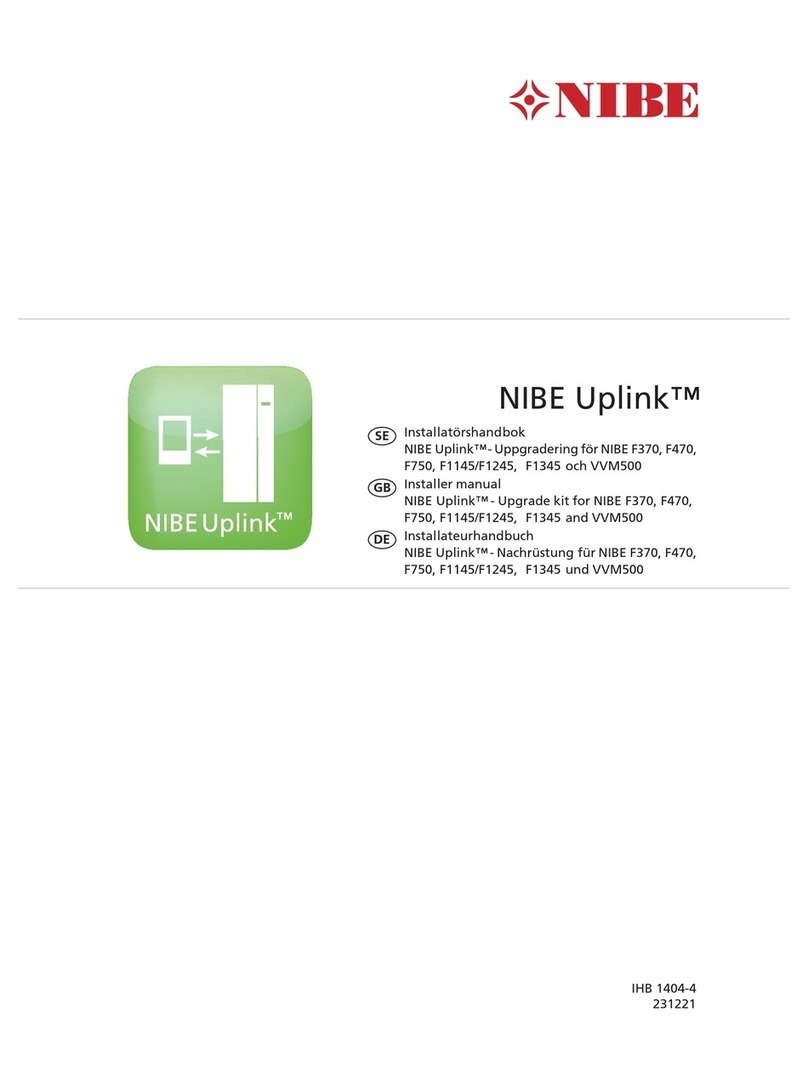

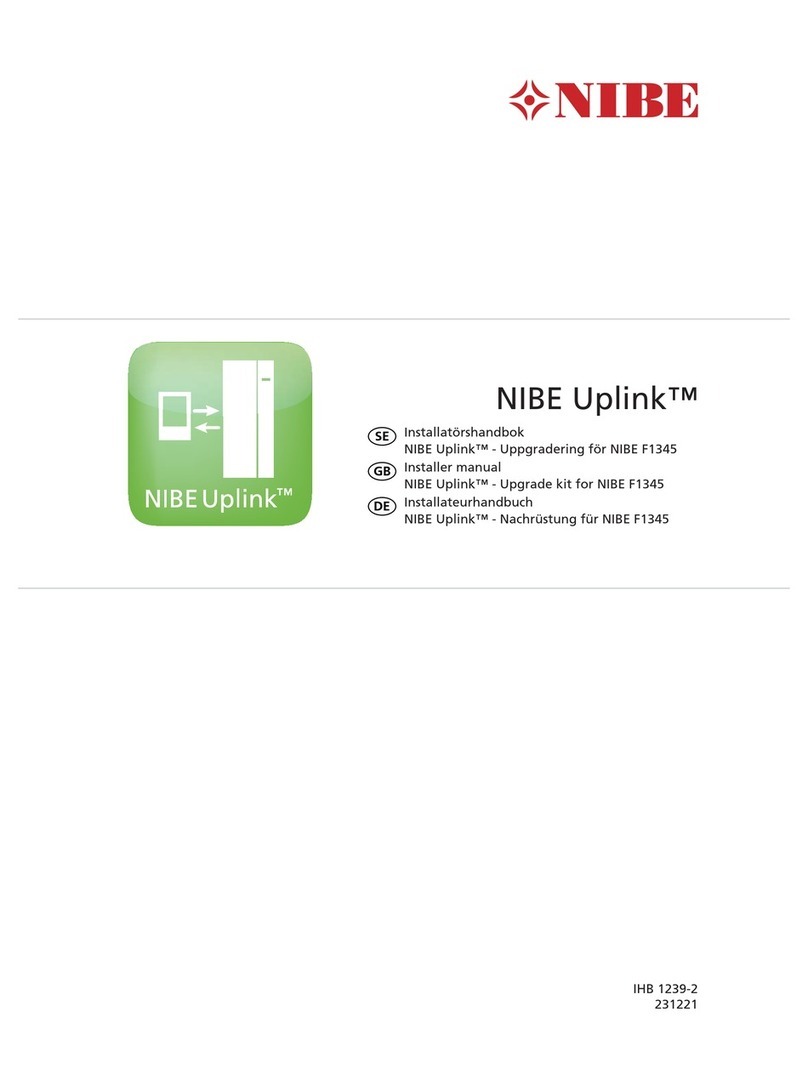

Outline diagram

Explanation

Heat pump system (Master)EB100

Temperature sensor, outdoorBT1

Temperature sensor, hot water chargingBT6

Temperature sensor, heating medium flow,

External

BT25

Temperature sensor, heating medium return,

External

BT71

Heat pump, F1345EB100

Cooling module AEP14

Cooling module BEP15

Safety valve, collector sideFL11 - FL12

Safety valve, heating medium sideFL13 - FL14

Particle filterHQ12 - HQ15

Shut-off valve, brine sideQM50 - QM53

Shut-off valve, heating medium sideQM54 - QM57

Reversing valve, heating/hot waterQN10

Non-return valveRM10 - RM13

External additional heatEM1

Accessory card (AXC 50)AA5

Temperature sensor, boilerBT52

Expansion vessel, closedCM5

Oil/gas boilerEM1

Safety valve, heating medium sideFL10

Auxiliary relay, external additional heatKA1

Mixing valve, additionQN11

Miscel-

laneous

Manometer, brine sideBP6

Temperature sensor, hot water flowBT70

Accumulator tank with hot water coilCP10, CP11

Buffer vessel, UKVCP20

Expansion vessel, closed, brine sideCM3

Collector, brine sideEP12

Safety valve, brineFL3

Circulation pump, heating medium externalGP10

Circulation pump, heating medium externalGP18

Venting valve, brine sideQM21

Shut off valve, brine flowQM33

Shut off valve, brine returnQM34

Non-return valveRM21

Trim valveRN60 - RN63

Connection, filling brineXL27 - XL28

Designations according to standards 81346-1 and 81346-

2.

Outline diagram F1345 with AXC 50 and external addition

-EB100-BT71

-EP12

-CM3

P

-BP6 -QM21 -FL3

-XL28-XL27

-QM33

-QM34

-EB100-BT1

-EB100-BT25

-HQ15

-HQ14

-RM12

-RM13

-QM54

-FL12

-QM55

-QM56

-QM57

-FL13

-HQ13

-RM11

-HQ12

-RM10-QM50

-QM51

-FL10

-QM52

-QM53

-FL11

-EB100

-EP15

-EP14

-EB100

-EB100

-BT6

-CP10

-RN63

-RN62

-CP11

-RN60

-RN61

-EB100-QN10

-QN11

-BT52

-EM1-AA5

-CM5

-FL10 -KA1

-EM1

-EM1

-RM21

-GP18

-CP20

-GP10

5Chapter 3 | Shunt controlled additional heatAXC 50