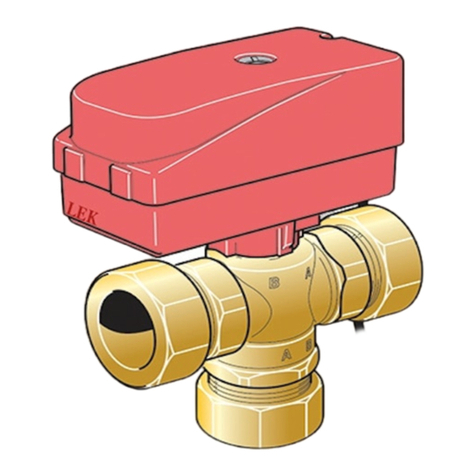

INSTALLING THE VALVE MOTOR

Example installation:

1. Ensure that the depression, in the shaft (1a) and the

shaft on the valve (1b), are at 12 o'clock with the

port up. In this example ▲ and ■ are open while ●

to begin with is closed.

2. Ensure that the knob on the motor is turned all the

way to the right.

3. Turn the knob to the left to close ■ and open ●.

180°

1. 2.

LEK

LEK

LEK

LEK

LEK

LEK

The symbols are marked on the terminals.

CHANGING THE DIRECTION OF ROTATION

NOTE

Electrical installation and service must be car-

ried out under the supervision of a qualified

electrician. Cut the current with the circuit

breaker before carrying out any servicing.

Electrical installation and wiring must be carried

out in accordance with the stipulations in force.

Change the direction of rotation on the valve motor as

necessary.

1. Slacken off the screws and cap on the valve motor.

180°

1. 2.

LEK

LEK

LEK

LEK

LEK

LEK

2. Pull out the pins, turn them 90 ° and put them back.

Electrical connection

NOTE

Electrical installation and service must be car-

ried out under the supervision of a qualified

electrician. Cut the current with the circuit

breaker before carrying out any servicing.

Electrical installation and wiring must be carried

out in accordance with the stipulations in force.

The valve motor is connected according to the following

diagram.

Brown

1 ~

L

Neutral

Control phase

MBlue

Black

QN10

For more information about electrical connections, see

relevant Installer manual/Assembly and maintenance

instructions for the system to which the reversing valve

is to be connected.

Technical

specifications

VST 20

230 V,~50 HzVoltage

40kWkWMax. charge power

DN32 (1 1/4”)Connection

16.0Kvs

089 388Part No.

VST 20 | GB6